Model G4000 (Mfg. Since 8/09)

-23-

4. slide the #1 jaw into the #1 jaw guide and

hold it firmly against the scroll gear threads,

then rotate the chuck key clockwise approxi-

mately one turn until the lead thread engages

with the jaw.

Note: Tug on the jaw to make sure it is

engaged with the scroll gear thread.

5. repeat Steps 3–4 for jaws #2 and #3 in

sequence.

6. rotate the chuck key clockwise to bring the

jaws together in the center of the chuck.

— if installed correctly, the jaws will converge

evenly at the center of the chuck.

— if the jaws do not come together evenly,

remove them, make sure the numbers of

the jaws and the jaw guides match, then

properly re-install them.

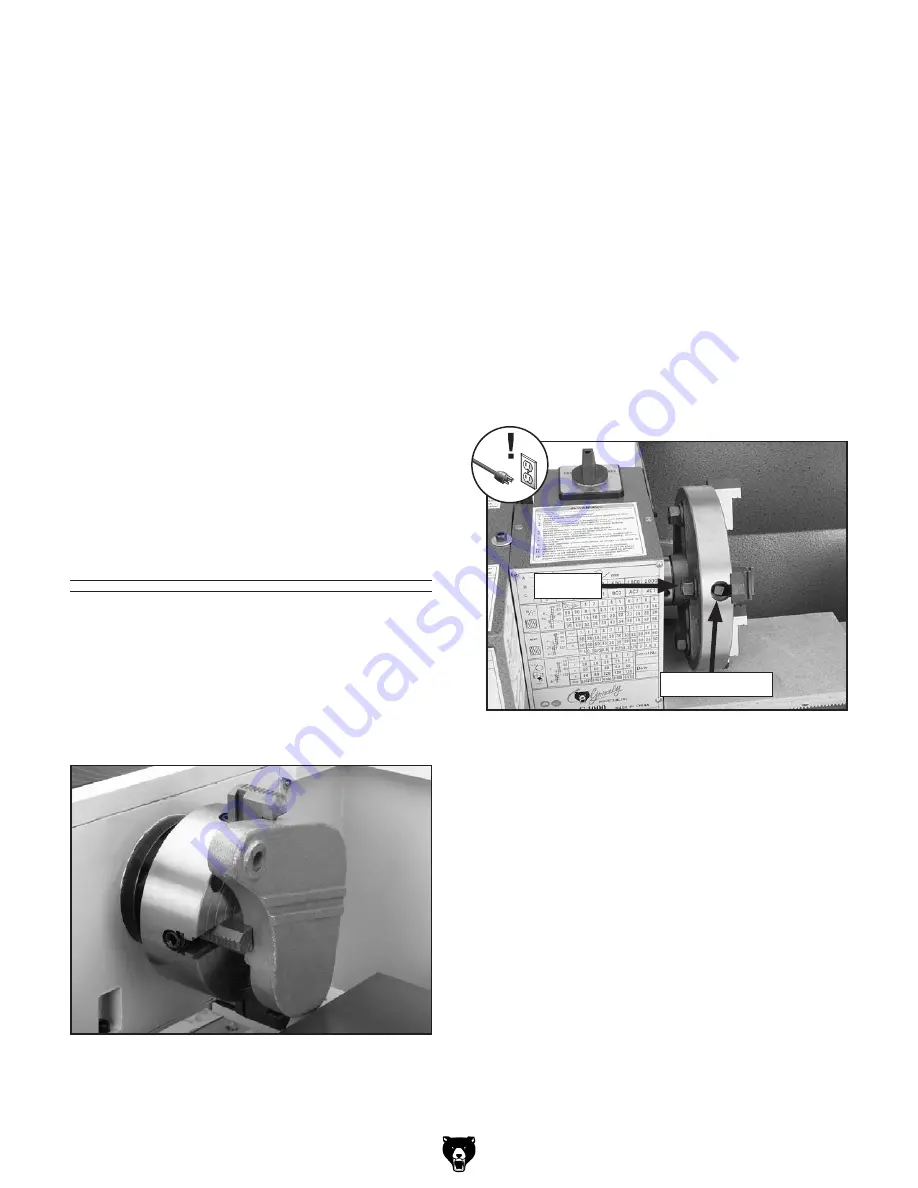

4-Jaw Chuck

the 4-jaw chuck included with your lathe features

independently adjustable, hardened steel jaws.

Each jaw can be removed from the chuck body

and reversed for a wide range of work holding

configurations. the 4-jaw chuck is typically used

to hold non-concentric workpieces (see

figure 20

for an example).

figure 20. Example of a non-concentric

workpiece held in a 4-jaw chuck.

Mount or remove the 4-jaw chuck according the

instructions beginning on

page 20.

Tools Needed

Qty

hex Wrench 3mm .............................................. 1

Wrench 19mm ................................................... 1

4-Jaw Chuck Key .............................................. 1

Mounting Workpiece

1. disConnECt LAthE FroM poWEr!

2. Lay a piece of plywood on the bedway under-

neath the spindle to protect the precision

ground surfaces.

3. Loosen the hex nut on the back of the chuck

for each jaw (see

figure 21).

4. With assistance to support the workpiece,

use the chuck key to open each jaw until you

can position the workpiece flat against the

chuck face or evenly on the jaw steps.

figure 21. 4-jaw chuck components.

hex nut

scroll Keyway