-22-

G4030 6

1

⁄

2

" x 10" Metal-Cutting Bandsaw

The speed at which the saw blade will cut through

a workpiece is controlled by blade type, feed rate,

and feed pressure.

Note:

If a lubricant is used on the cut, the feed

rate can be increased by approximately 15%

.

To set the feed rate:

1.

Raise the headstock to the vertical position.

2.

Using a 14mm wrench, adjust the feed

pressure tension spring. Tighten enough

to remove play but not enough to apply

tension to the spring (see

Figure 22

).

Note:

This spring adjustment is an

initial setting. Depending on cutting

circumstances, you will have to fine-tune

the feed pressure with this adjustment.

Increasing the spring tension will reduce the

feed pressure.

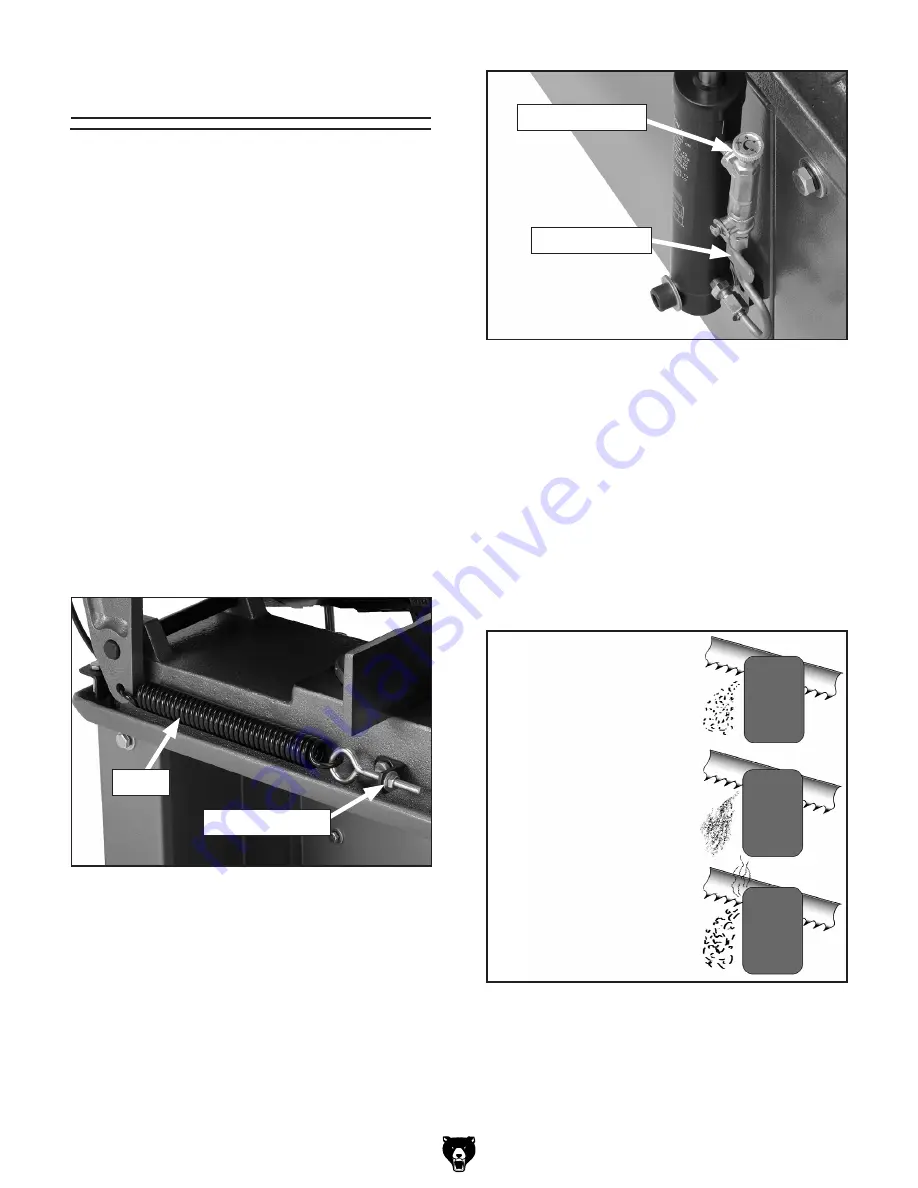

Figure 24.

Reading chip characteristics.

Chips are silvery,

thin, small, or

powdery: Increase

feed rate.

Chips are large,

curled, blue or

brown, or smoking:

Decrease feed rate.

Chips are width

of tooth, thin and

curled, and silvery:

Optimum speed and

feed rate.

Feed Rate

3.

Clamp the workpiece in the table vise.

4.

Close the feed ON/OFF valve to lock the

headstock and blade a few inches above the

workpiece (see

Figure 23

).

Figure 22

. Spring tension adjustment.

Spring

Adjustment Nut

Figure 23

. Feed rate dial.

Feed Rate Dial

ON/OFF Valve

5.

With the correct saw blade and blade speed

selected, turn the saw and lubricant pump

ON

.

6.

Slowly rotate the feed rate dial clockwise to

a slow feed rate until the saw begins to cut

the workpiece (see

Figure 23

).

7.

Observe the chips that exit the cut, and

increase or decrease the feed rate according

to the chip characteristics (see

Figure 24

).

Summary of Contents for G4030

Page 15: ...G4030 61 2 x 10 Metal Cutting Bandsaw 13 Hardware Recognition Chart...

Page 37: ...G4030 61 2 x 10 Metal Cutting Bandsaw 35 Parts Breakdown G4030...

Page 38: ...36 G4030 61 2 x 10 Metal Cutting Bandsaw Parts Breakdown G4030...

Page 39: ...G4030 61 2 x 10 Metal Cutting Bandsaw 37 Parts Breakdown G4030...

Page 47: ......