10

©Alcor 2011 All rights reserved

MOUNTING ATTACHMENTS

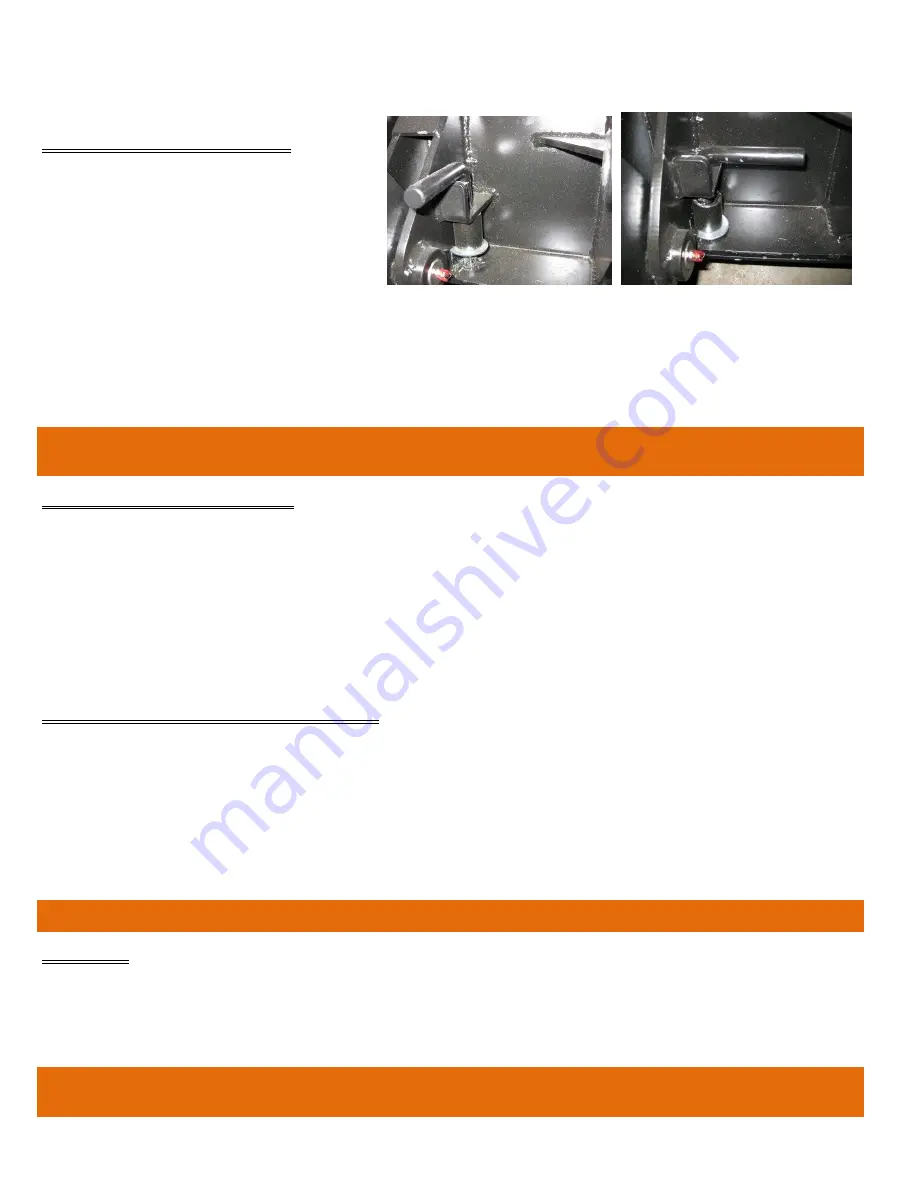

Check and clean the attachment plate

surfaces and place the lock pins in the

unlocked position. (Fig. 8)

Check that all controls are in their neutral

or “OFF” position. (Fig. 3)

Stand on the operator platform and start

the engine.

Drive up to the attachment and line up the attachment plate with the attachment’s mating plate lip.

Tilt the attachment plate back lifting the attachment off the ground just enough. Lift the loader arms is necessary.

Turn the engine off. (Fig. 7)

Place the lock pins in their locked position and make certain they are inserted all the way threw the pin holes on the

attachment. (Fig. 9)

WARNING;

DO NOT OPERATE THE MACHINE WITH AN ATTACHMENT THAT IS NOT

PROPERLY SECURED BY THE LOCK PINS.

RELEASING ATTACHMENTS

Drive the G41 to the area where the attachment will be released.

Set the attachment close to the ground in a way that the lock pins can be turned to the unlocked position. (Fig. 8)

Turn the engine off. (Fig. 7)

Place the lock pins in their unlocked position. (Fig. 8)

Start the engine.

Lower the attachment to the ground and tilt the attachment plate forward to disengage from the attachment’s mating

plate lip.

Reverse away from the attachment.

OPERATING THE STANDARD BUCKET

Do not lift more than 500 lbs, (including bucket) or machine may become unstable and tip forward.

When operating with a full bucket, travel forward and reverse with the bucket as close as possible to the ground, turn

with caution.

A full bucket will change the way the machine pivots when turning, moving the pivot position from the rear wheels

to the front wheels.

Move as close as possible to the dump area and stop before lifting to dump.

Lift the loader arms slowly to have a feel for the balance of the machine. Dump the load as soon as possible.

WARNING:

NEVER TRAVEL OR TURN WITH A RAISED BUCKET

LOUVERS

The G41 is equipped with louvers to protect the hydraulic components from falling debris.

The machine can be used without the louvers on very hot days where prolonged use may generate a lot of heat.

It is up to the operator to decide if the work being performed allows the machine to be used without these protective

louvers.

WARNING:

ALWAYS USE THE CYLINDER LOCK WHEN REMOVING OR INSTALLING

THE LOUVERS.

Unlocked position

Locked position

Fig. 8

Fig. 9