Model G9743 (Mfg. since 12/07)

-31-

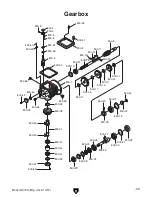

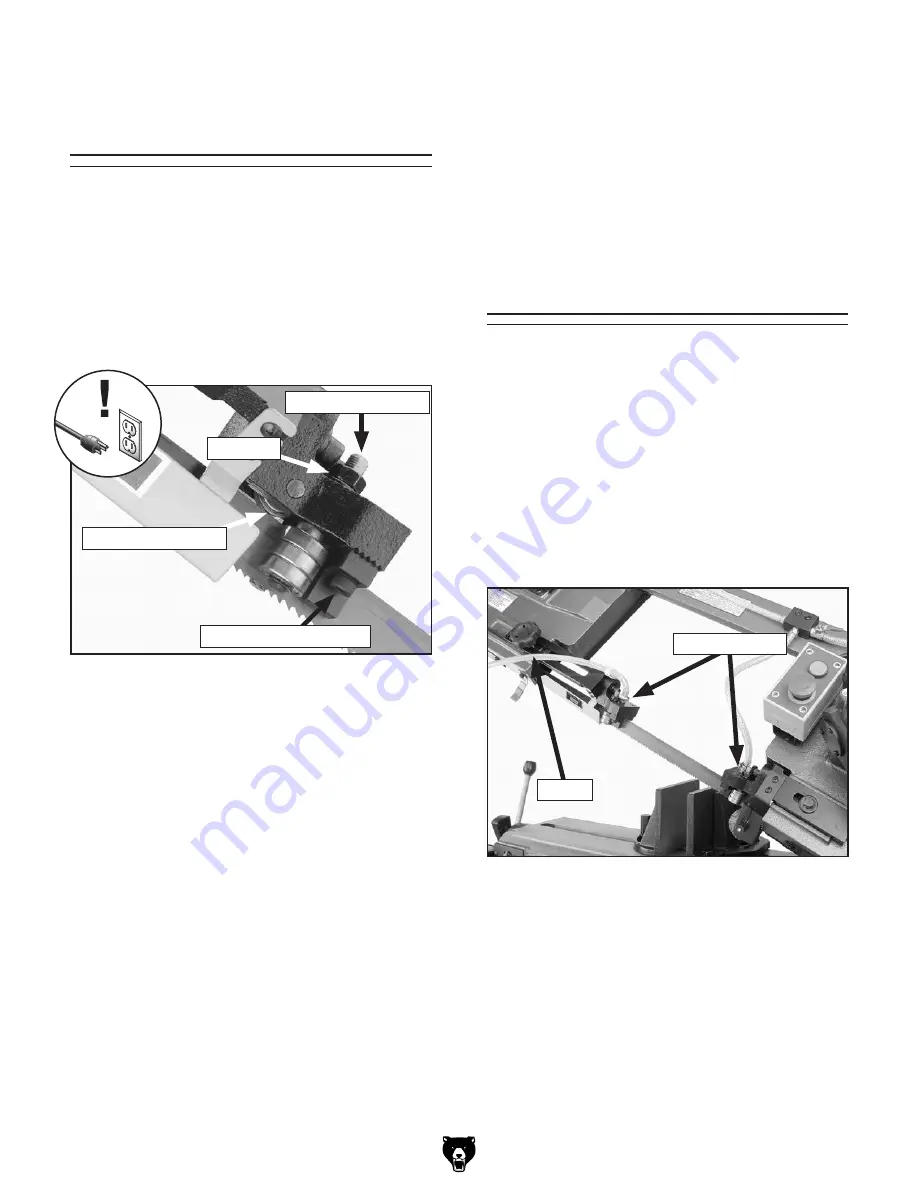

The blade guide bearings come adjusted from the

factory and the need for adjustment should rarely

occur. Uneven blade wear and crooked cuts

may be the result of improper adjustment. Each

bearing assembly has an eccentric bushing that

allows the distance between the blade and bear-

ings to be adjusted. The bearings are secured in

place by a hex nut and a lock washer as shown

in

Figure 33

.

Blade Guide

Bearings

To adjust the blade guide bearings:

1.

UNPLUG THE BANDSAW!

2.

Raise the bandsaw to the highest position

and close the feed rate ON/OFF valve.

3.

Loosen the hex nut that secures the eccentric

bushing.

4.

Adjust the eccentric bushing position to

achieve the desired clearance. The bearing

and blade should make light contact or have

a clearance of 0.001"-0.002".

5.

Tighten the nut to lock the eccentric bushing

and bearing in position.

Figure 33.

Blade guide adjustments.

Hex Nut

Backing Bearing

Eccentric Bushing

Carbide Blade Guide

Blade Guides

The blade guides should be as close to the

workpiece as possible. This will help ensure

straight cuts by keeping the blade from twisting

and drifting off the cut line.

To adjust the blade guides:

1. Loosen the knob shown in Figure 34 and

slide the rear blade guide as close to the

workpiece as possible, then tighten the

knob.

Figure 34. Blade guides.

Blade Guides

Knob

6.

Adjust the other eccentric blade guide bear-

ing in the same manner. The backing bear-

ing is not adjustable and will make light

contact with the blade.

7

. Adjust the carbide blade guides so they

make the same contact with the blade as

the bearings.

Summary of Contents for G9743

Page 15: ...Model G9743 Mfg since 12 07 13 5mm Hardware Recognition Chart...

Page 47: ...Model G9743 Mfg since 12 07 45 Notes...

Page 51: ......