-30-

G9744Z Metal Cutting Bandsaw

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

al injury.

SECTION 6: MAINTENANCE

Lubrication

Cleaning the Model G9744Z is relatively easy.

After using your bandsaw, remove excess chips

by sweeping. Then remove chips for recycling.

Wipe down the machine and remove any stand-

ing coolant.

Cleaning

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check:

•

Loose mounting bolts.

•

Damaged saw blade.

•

Worn or damaged wires.

•

Any other unsafe condition.

•

Clean after each use.

•

Proper blade tension.

•

Coolant level.

•

Coolant condition.

Monthly Check:

•

Lubricate vise screw.

•

Check gear box fluid level

.

Annual Check:

•

Change gear box oil (every four months if

being used daily)

.

Schedule

Since all bearings are sealed and permanently

lubricated, leave them alone until they need to be

replaced. Do not lubricate them. However, you

must periodically lubricate threaded adjustment

locations and check the gear box oil level.

Lubricate the following areas as follows:

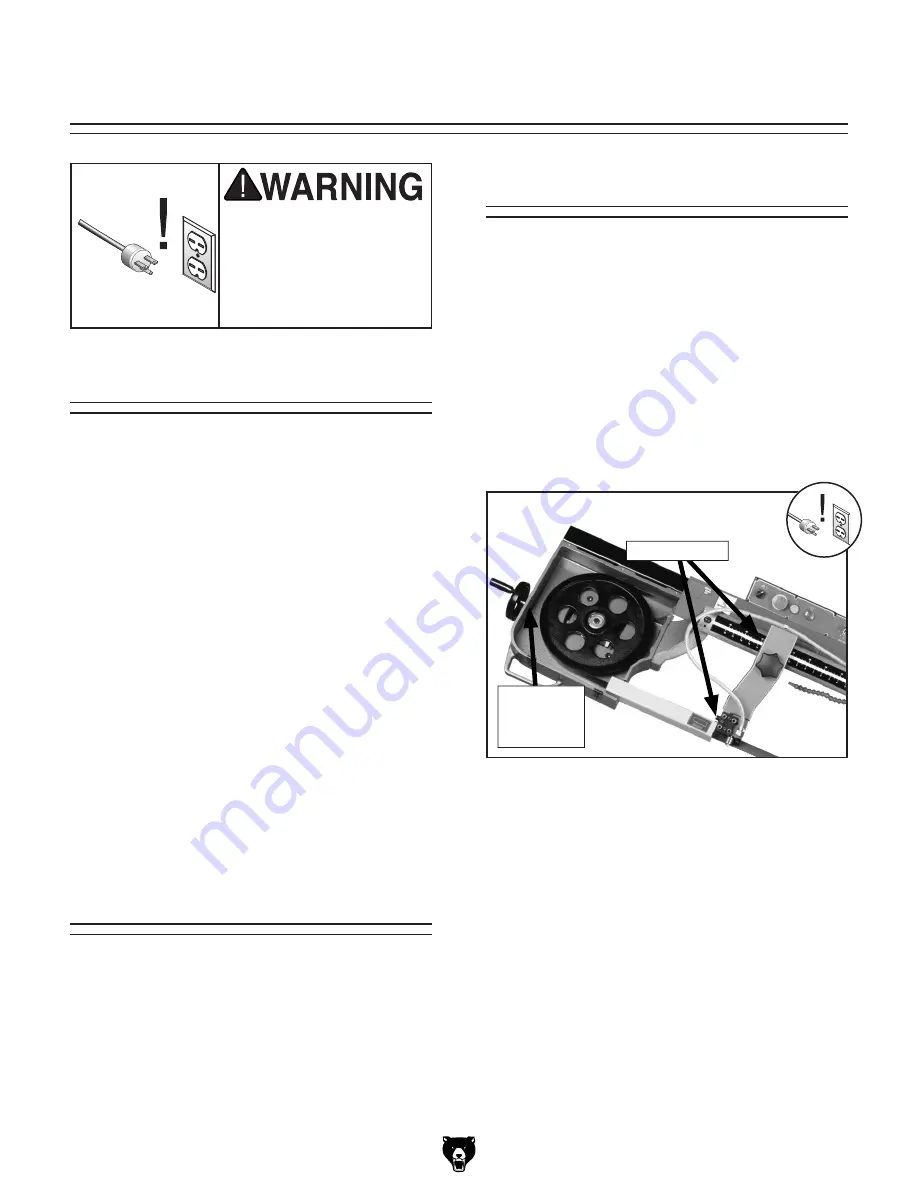

•

Blade Tension Mechanism:

Open the main

blade guard and drop a few drops of oil on

the tension knob lead screw (see

Figure

33

).

Figure 33

. Main lubrication points.

Tension

Knob Lead

Screw

Blade Guide

Summary of Contents for G9744Z

Page 2: ......

Page 16: ...14 G9744Z Metal Cutting Bandsaw Hardware Recognition Chart...

Page 42: ...40 G9744Z Metal Cutting Bandsaw Blade Guide Parts Breakdown...

Page 43: ...G9744Z Metal Cutting Bandsaw 41 Drive Wheel Parts Breakdown...

Page 44: ...42 G9744Z Metal Cutting Bandsaw Main Parts Breakdown...

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......