H6141 Air Palm Nailer

-9

-

Replacing Pistons/O-

Rings

If you use your nailer day in and day out,

replacement pistons are cheap insurance

against wasted down time and lost profits,

in the event that a piston or piston shaft

becomes worn out.

6.

Push the ram pin towards the inside of

the nailer. This will push the cylinder

free of the housing.

7.

Remove the piston from the cylinder

by pulling it free by the ram pin.

8.

Place a new O-ring on the new piston

and apply a thin film of the nailer lubri-

cating oil on the O-ring.

9.

Insert the new piston in the cylinder.

The new piston should easily slide

into the cylinder.

DO NOT force the

piston into the cylinder!

If the piston

is not easily inserted, double-check

the alignment of the piston inside the

cylinder.

10.

After the piston is inserted correctly,

place the cylinder back in the housing.

If seated correctly, the cylinder will

snap into place.

11.

Push the cylinder collar down into

the housing as far as it will go. The

horizontal air slots on the side of the

cylinder should be visible.

12

. Replace the rear cap assembly and

tighten the four cap screws.

13.

Replace the flat washer, compression

spring, depth guide and nose piece

and tighten using a 19mm wrench.

14.

For more assistance, or to install a

complete O-ring set, refer to the appro-

priate breakdown diagram in the back

of this manual for component loca-

tions.

To replace a piston:

1.

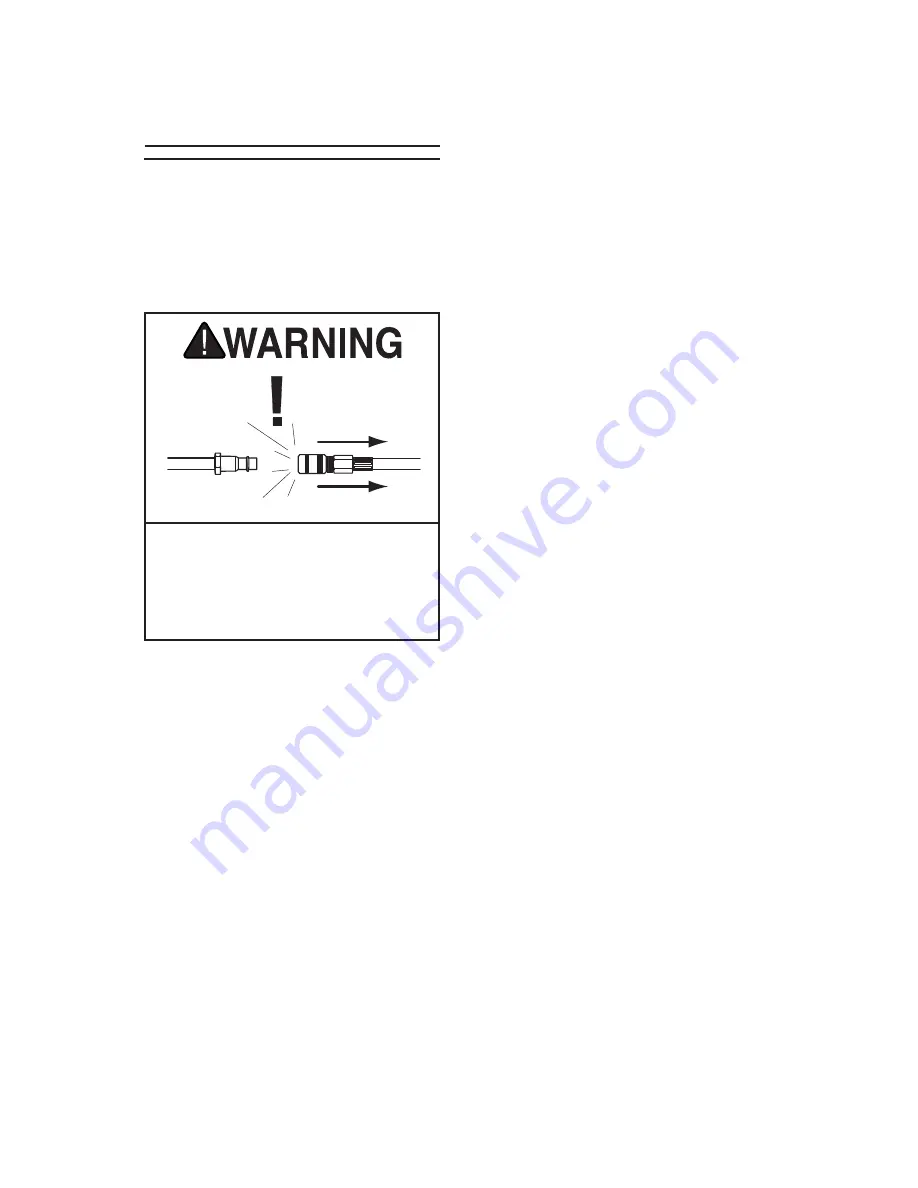

DISCONNECT NAILER FROM THE

AIR SUPPLY!

2.

Unscrew the nose piece with a 19mm

wrench.

3.

Remove the nose piece, depth guide,

compression spring and flat washer.

4.

Remove the four cap screws and

washers on the back of the nailer.

5.

Remove the cap.

Always disconnect air from nailer

whenever servicing! During mainte-

nance, a nailer connected to air may

fire accidentally, causing serious

personal injury!

Summary of Contents for H6141

Page 13: ......