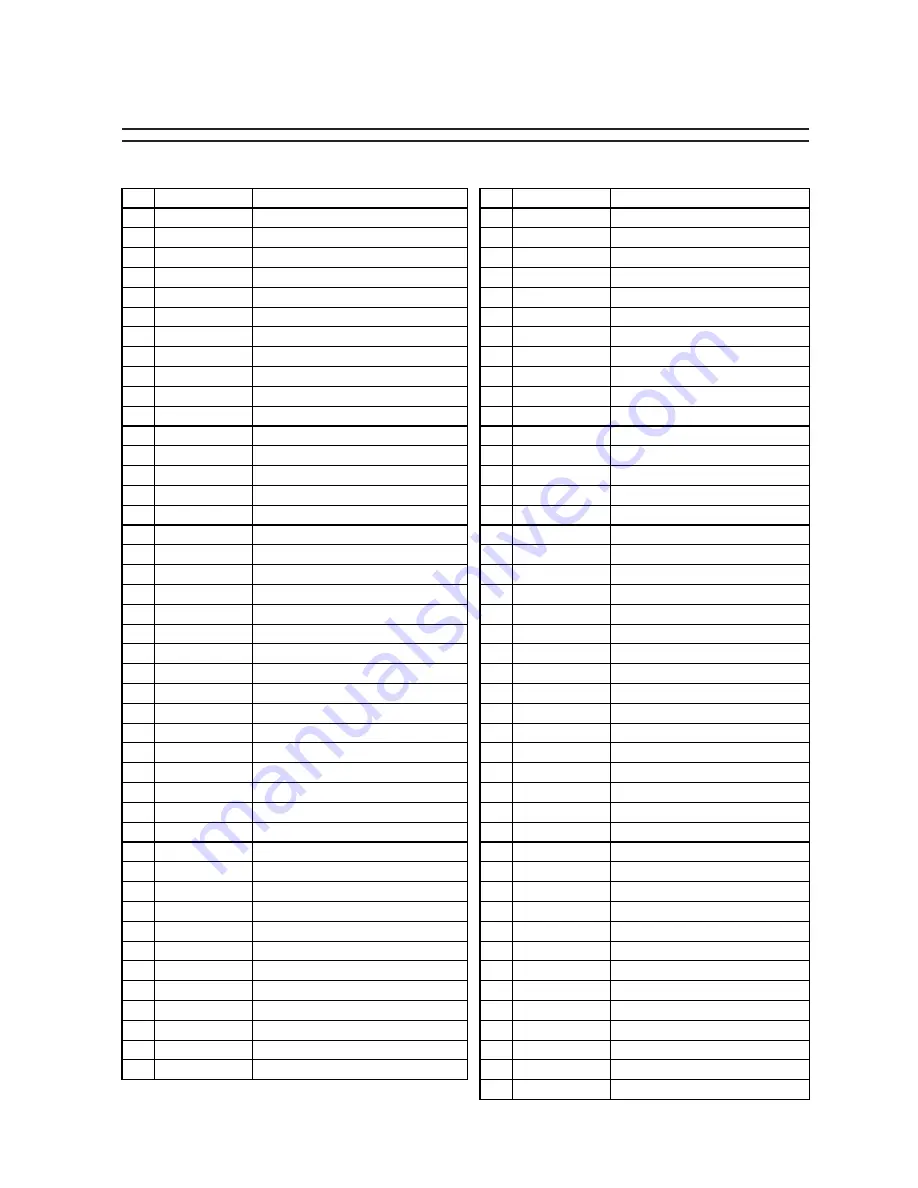

H6146 34° Clipped Head Framing Nailer

-14

-

H6146 PARTS LIST

PART #

DESCRIPTION

REFPART #

DESCRIPTION

1

PH6146001 SPCL CAP SCR M8-1.25 X 30

47 PSB03M

CAP SCREW M5-.8 X 8

2

PH6146002 AIR DEFLECTOR

48 PW02M

FLAT WASHER 5MM

3

PH6146003 RUBBER WASHER

49 PH6146049 ADJUSTING NUT

4

PH6146004 SPRING

50 PH6146050 SAFETY YOKE

5

PH6146005 SPRING WIRE

51 PH6146051 SAFETY NOSE

6

PSB06M

CAP SCREW M6-1 X 25

52 PH6146052 COPPER COLLAR

7

PLW03M

LOCK WASHER 6MM

53 PH6146053 SAFETY NOSE CASE

8

PH6146008 CYLINDER CORE

54 PH6146054 O-RING 61.5 X 1.8

9

PSS07M

SET SCREW M5-.8 X 5

55 PH6146055 DRIVER GUIDE

10 PH6146010 CYLINDER COVER

56 PLW04M

LOCK WASHER 8MM

11 PH6146011 HEAD VALVE PISTON

57 PSB13M

CAP SCREW M8-1.25 X 30

12 PH6146012 SPRING SEAT

58 PS14M

PHLP HD SCR M6-1 X 12

13 PH6146013 COMPRESSION SPRING

59 PH6146059 MAGAZINE

14 PH6146014 O-RING 56.7 X 3

60 PW03M

FLAT WASHER 6MM

15 PH6146015 COLLAR

61 PLN03M

LOCK NUT M6-1

16 PH6146016 O-RING 42.3 X 5

62 PH6146062 DRIVE NAIL BAR

17 PH6146017 PISTON

63 PSB18M

CAP SCREW M4-.7 X 8

18 PH6146018 O-RING 57.5 X 3

64 PLN01M

LOCK NUT M4-.7

19 PH6146019 O-RING 88 X 3

65 PSB46M

CAP SCREW M4-.7 X 40

20 PH6146020 FIXED RING

66 PH6146066 SAFETY PIPE

21 PH6146021 SEALING RING

67 PH6146067 SAFETY PIPE CASE

22 PH6146022 CYLINDER

68 PH6146068 PIN CASE

23 PH6146023 BUMPER

69 PRP23M

ROLL PIN 4 X 44

24 PH6146024 GASKET

70 PH6146070 PUSHER

25 PH6146025 BODY

71 PH6146071 PIN 3 X 20

26 PH6146026 RUBBER WASHER

72 PH6146072 PIN 5 X 20

27 PH6146027 TRIGGER VALVE SEAT

73 PSB93M

CAP SCREW M3-.5 X 14

28 PH6146028 O-RING 15 X 2.65

74 PN07M

HEX NUT M3-.5

29 PH6146029 O-RING 17 X 1.5

75 PH6146075 PIN 4 X 30

30 PH6146030 TRIGGER VALVE GUIDE

76 PH6146076 TORSION SPRING

31 PH6146031 O-RING 6.2 X 1.8

77 PH6146077 SPRING CORE

32 PH6146032 O-RING 6.4 X 2

78 PH6146078 PIN 5 X 12

33 PH6146033 O-RING 9 X 1.8

79 PH6146079 RELEASE LATCH

34 PH6146034 SWITCH SPRING

80 PH6146080 TORSION SPRING

35 PH6146035 SWITCH PIPE

81 PSB38M

CAP SCREW M5-.8 X 25

36 PH6146036 O-RING 2.5 X 1.5

82 PW02M

FLAT WASHER 5MM

37 PH6146037 O-RING 20.3 X 2.3

83 PH6146083 FIXED SEAT

38 PH6146038 SWITCH SEAT

84 PLN02M

LOCK NUT M5-.8

39 PH6146039 TRIGGER PIN

85 PH6146085 RUBBER HANDLE CASE

40 PH6146040 TRIGGER

86 PH6146086 GASKET

42 PH6146042 SAFETY SPACER

87 PH6146087 END CAP

43 PRP02M

ROLL PIN 3 X 16

88 PLW01M

LOCK WASHER 5MM

44 PH6146044 SAFETY GUIDE

89 PSB15M

CAP SCREW M5-.8 X 20

45 PH6146045 PIN 3 X 25

90 PH6146090 1/4" NPT MALE CONNECT

46 PH6146046 COMPRESSION SPRING

91 PH6146091 AIR PLUG COVER

92 PW02M

FLAT WASHER 5MM