Maintenance

Lubricate at the beginning of the sanding task.

Place one or two drops of pneumatic tool oil

directly into the air fitting as shown in

Figure 5

.

Figure 5

.

Lubricating directly into air fitting.

Operation

To operate the sander:

1.

Plug the tool into compressed air and turn

ON

the optional canister vacuum.

2.

Hold the sander and press the throttle lever

(

Figure 4

) to turn the sander

ON

.

Considerable caution must be used with an inline

lubricator set up, as excess oil will be expelled

from the sander onto the workpiece. If you must

use an inline lubricator, monitor the exhaust port

for oil emissions to avoid spraying oil on your

workpiece.

Before installing the sanding disc, run the sander

for a few minutes to eject excess oil, then wipe

the tool down with a clean rag and begin sanding.

Oil the tool after use or storage.

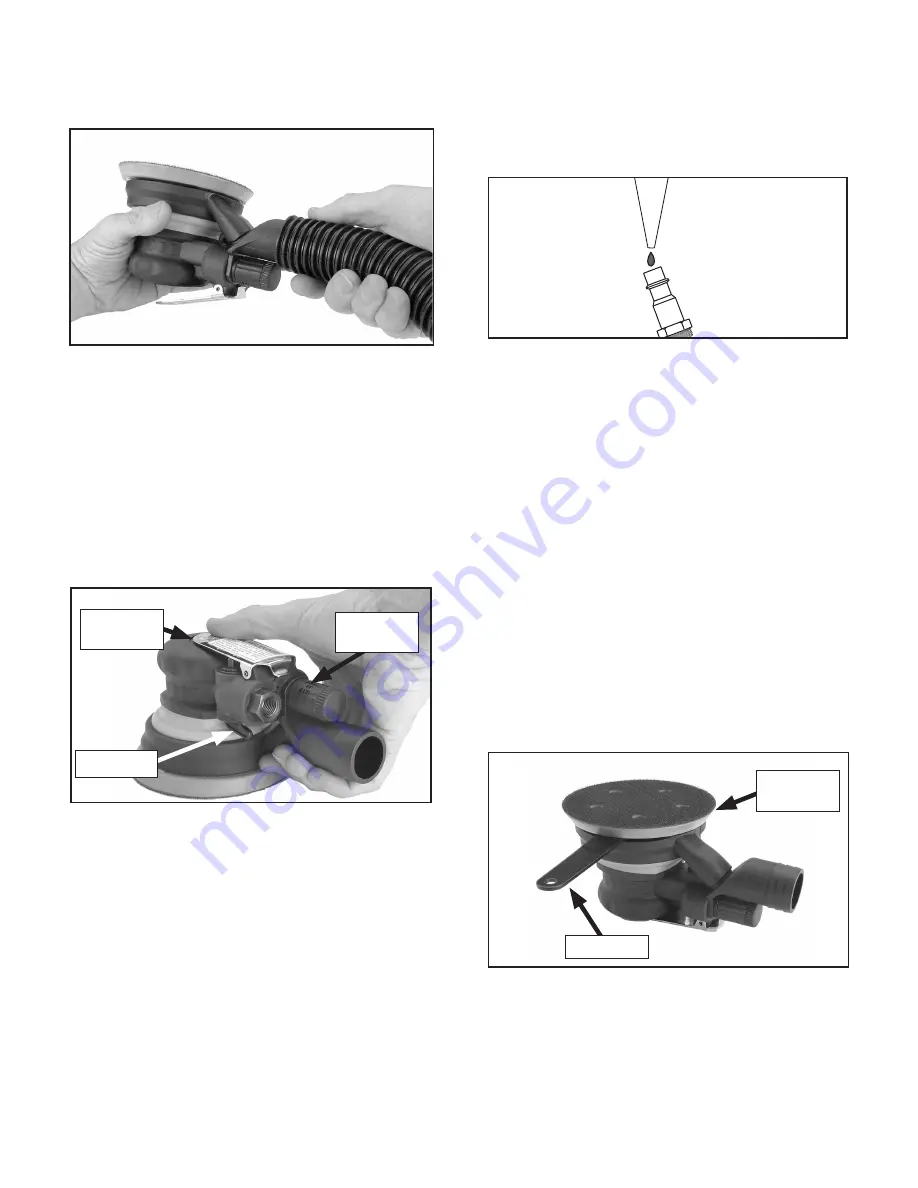

Service

To replace the sanding pad:

1.

Insert the included wrench onto the spindle

as shown in

Figure 6

.

3.

Turn the regulator (

Figure 4

) to adjust the

sanding pad speed to a fixed rate, and rotate

the directional exhaust port.

4.

Remove pressure on the throttle lever to stop

the sanding pad, then turn the vacuum

OFF

.

5.

When the sandpaper loses its effectiveness,

disconnect the sander

and replace the

sandpaper.

If you need help with your new pneumatic tool, call

our Tech Support at: (570) 546-9663.

Figure 4

. Sander controls.

Figure 6

. Wrench inserted onto spindle.

2.

Hold the wrench and unscrew the sanding

pad.

3.

Install a new sanding pad (Part # PH6192039)

and secure it with the wrench.

Wrench

Sanding

Pad

3.

(Optional) Attach the sander to a 1

1

/

4

" vacu-

um hose as shown in

Figure 3

.

Figure 3.

Attaching sander to 1

1

/

4

" canister

vacuum hose.

Regulator

Exhaust

Port

Throttle

Lever