Shop Fox

®

Classic Fence

-15-

Attaching the wood facing to the fence:

1.

Size a suitable piece of wood for the face

of the fence.

2.

Drill and counterbore six

3

⁄

8

" mounting

holes in the wood face piece using the

HDPE supplied fence facing as a drill

guide.

3.

Attach the wood facing to the fence,

making sure the screws are counterbored

1

⁄

8

"

-

1

⁄

4

" below the wood surface. Do not

over tighten.

To operate this, or any tool, safely and

efficiently, it is essential to become as familiar

with its characteristics as possible. Take as

much time as necessary to become acquainted

with the

SHOP FOX

®

Classic Fence. The time

you invest before you begin to use it will be

time well spent.

Operation of this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glasses

or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses

you wear meet the appropriate standards of

the American National Standards Institute

(ANSI).

It is extremely important to attach the wood

facing correctly. Lumber less than

3

⁄

4

" is not

recommended. Screws or fasteners must be

counter sunk at least

1

⁄

8

" below the wood

surface, but no more than

1

⁄

4

".

Using Board Buddies

®

A T-slot track can be mounted in the top of the

SHOP FOX

®

Classic Fence to accept another

popular product from Woodstock International

- Board Buddies

®

. These one directional, spring

loaded hold-down wheels keep material pressed

firmly against the table and fence. They are

fully adjustable and non-marking.

Be sure to request the T-nuts and T-slot

tracks separately from your Woodstock dealer

for mounting Board Buddies

®

to your fence.

Board Buddies

®

are a great addition to any

fence system! For the location of your nearest

Woodstock dealer, call Woodstock International

at (360) 734-3482.

Using a Wood Fence

Facing

The

SHOP FOX

®

Classic Fence can be faced

with

3

⁄

4

" kiln dried hardwood, plywood or

medium density fiber board (MDF) in place

of the HDPE plastic fence sides. For certain

operations such as dadoing or close sawing, it

is necessary to have a fence material which

can be cut into. If using kiln dried lumber, use

a piece that is free of knots and other defects

and preferably a species with dimensional

stability such as maple, birch or beech.

OPERATIONS

Summary of Contents for H6472

Page 3: ......

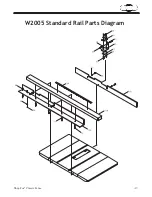

Page 20: ...Shop Fox Classic Fence 17 26 W2005 Standard Rail Parts Diagram ...

Page 23: ......

Page 24: ......

Page 25: ......