Model H8235 3-Piece Framing/Brad/Palm Nailer Kit

-11

-

Depending on the type of stock and nails

you are using, it may be necessary to

adjust the depth of nail penetration for your

framing nailer.

To adjust the depth for your framing

nailer:

1.

DISCONNECT NAILER FROM THE

AIR SUPPLY!

2.

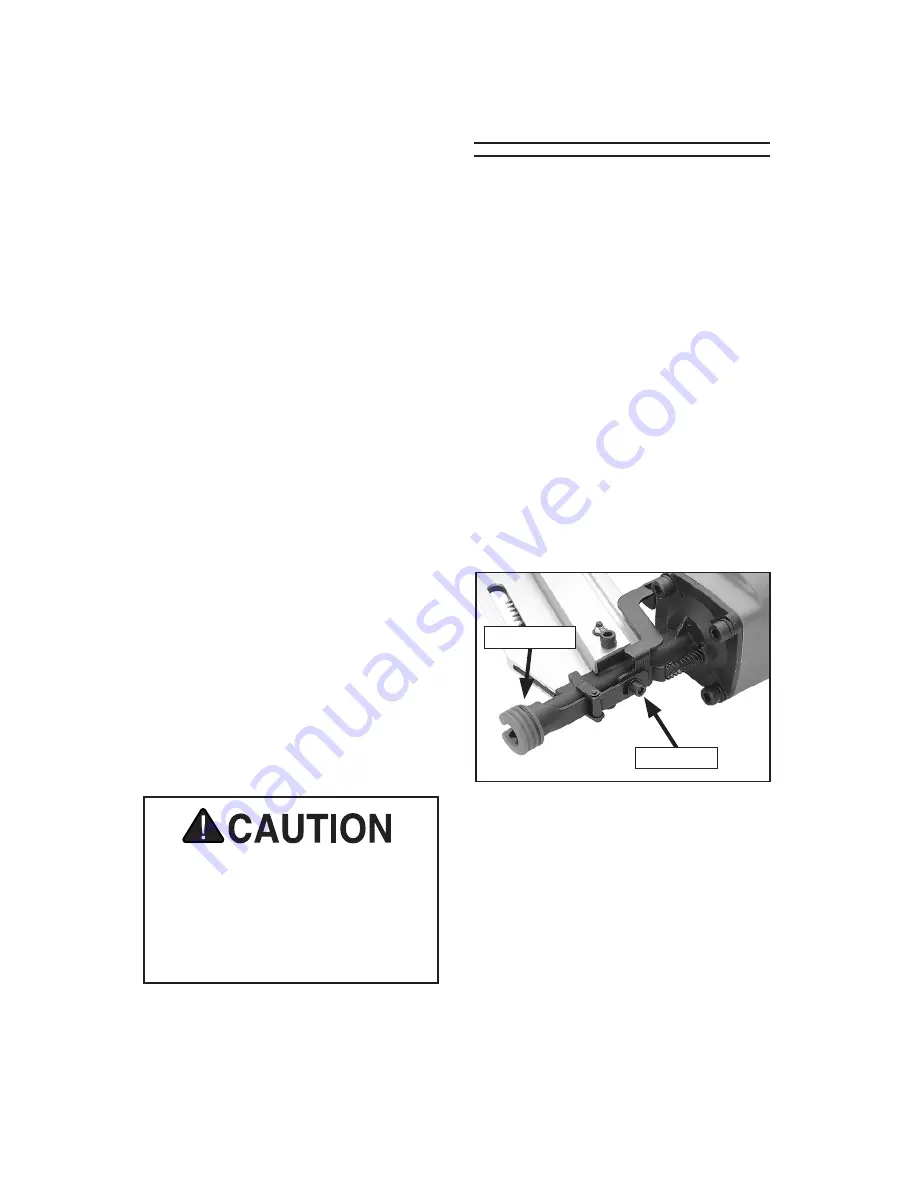

Use a 4mm hex wrench to loosen the

cap screw shown in

Figure 8

.

3.

Move the safety nose away from the

nailer body to decrease nail depth, and

toward the nailer body to increase nail

depth.

Adjusting Framing

Nailer Depth

4.

Re-tighten the cap screw, then connect

the nailer to the air supply and test the

nail depth.

5.

Repeat

Steps 2–4

, if necessary, until

the nail depth is satisfactory.

Figure 8.

Loosening cap screw for depth

adjustment.

Safety Nose

Cap Screw

Palm Nailer

1.

Connect the air supply to the quick con-

nect fitting.

2.

Make sure your free hand and other

body parts are positioned out of the

way of a potential path of a nail in case

of deflection.

3.

Hold the nail firmly in place with one

hand as if using a regular hammer.

4.

Place the tip of the palm nailer over

the top of the nail. When the ram pin

touches the nail head, the nailer will

automatically begin to hammer the nail

into place.

5.

Hold the nailer in place until the sliding

depth guide is completely depressed

up into the nailer and the nail is fully

hammered into the workpiece.

Note:

You can stop the nailer at any

time by simply lifting it away from

the nail. This is useful if you do not

want to countersink the nail into the

workpiece.

If the nailer is allowed to continue

hammering until it stops by itself, it will

countersink the nail to an approximate

depth of 2mm or

5

⁄

64

".

DO NOT attempt to adjust the depth on

your brad nailer. The nose of the brad

nailer is not designed to be adjusted.

Doing so could cause the safety nose

mechanism to malfunction and cause

personal injury.