-20-

H8259 10" x 18" Benchtop Lathe

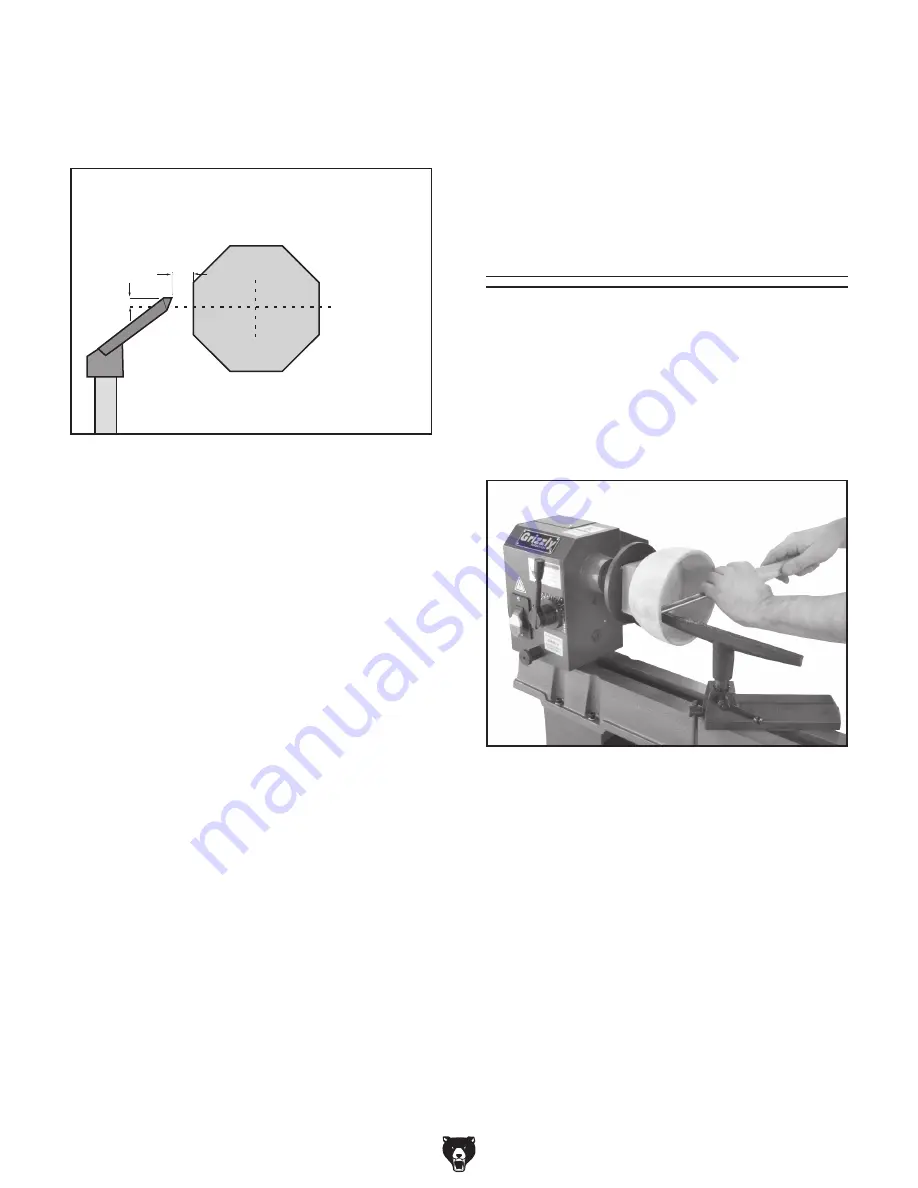

Faceplate turning (

Figure 27

) is when a workpiece

is mounted to the faceplate, which is mounted to

the headstock spindle. This type of turning is usu-

ally done with open-faced workpieces like bowls.

If screws cannot be placed in the workpiece, then

a backing block can be glued to the workpiece

and attached to the faceplate with screws.

Figure 27.

Typical faceplate turning operation.

To mount your workpiece to the faceplate:

1.

Find the center of your workpiece in the same

manner as when spindle turning.

2.

Cut off the corners of the workpiece.

3.

Center the faceplate on the workpiece and

attach it through the faceplate holes with

non-tapered head wood screws as shown in

Figure

28

.

4.

Thread the faceplate onto the headstock

spindle and tighten securely.

Faceplate Turning

•

Turn the lathe

OFF

immediately if the

workpiece vibrates excessively. Check to

make sure the workpiece is centered and

balanced. Remove the workpiece and trim

excess waste off corners with a bandsaw or

table saw to reduce vibration. Make sure the

workpiece is securely attached in the setup.

9.

Position the tool rest approximately

1

⁄

4

" away

from the workpiece and approximately

1

⁄

8

"

above the center line, as shown in

Figure

26

.

10.

Test the setup by hand-turning the workpiece

to make sure there is enough clearance all

the way around before starting.

Spindle Turning Tips:

•

When turning the lathe

ON

, stand to the side

of the spinning direction until the lathe reach-

es full speed and you can verify that the lathe

will not throw the workpiece.

•

Use the slowest spindle speed when rough

cutting.

•

Select the right speed for the size of workpiece

you are turning. Use slower speeds for

large workpieces (4" diameter and over); use

the middle range speeds for medium sized

workpieces (2" to 4" diameter); and use faster

speeds for small sized workpieces (under 2"

in diameter).

•

Keep the turning tool on the tool rest the

ENTIRE time that it is in contact with the

workpiece.

•

Learn the correct techniques for each tool

you will use. If you are unsure, read books or

magazines about lathe techniques and seek

training from experienced users.

���������

�����������

���������

���������

�

�

�

�

�

�

�

�

Figure 26.

Tool rest position.

Summary of Contents for H8259

Page 2: ... ...

Page 5: ...H8259 10 x 18 Benchtop Lathe 3 ...

Page 6: ... 4 H8259 10 x 18 Benchtop Lathe ...

Page 8: ... 6 H8259 10 x 18 Benchtop Lathe ...

Page 9: ...H8259 10 x 18 Benchtop Lathe 7 ...

Page 30: ... 28 H8259 10 x 18 Benchtop Lathe Main Breakdown ...

Page 33: ... ...

Page 34: ... ...

Page 36: ... ...