-38-

Model G0833P (Mfd. Since 06/17)

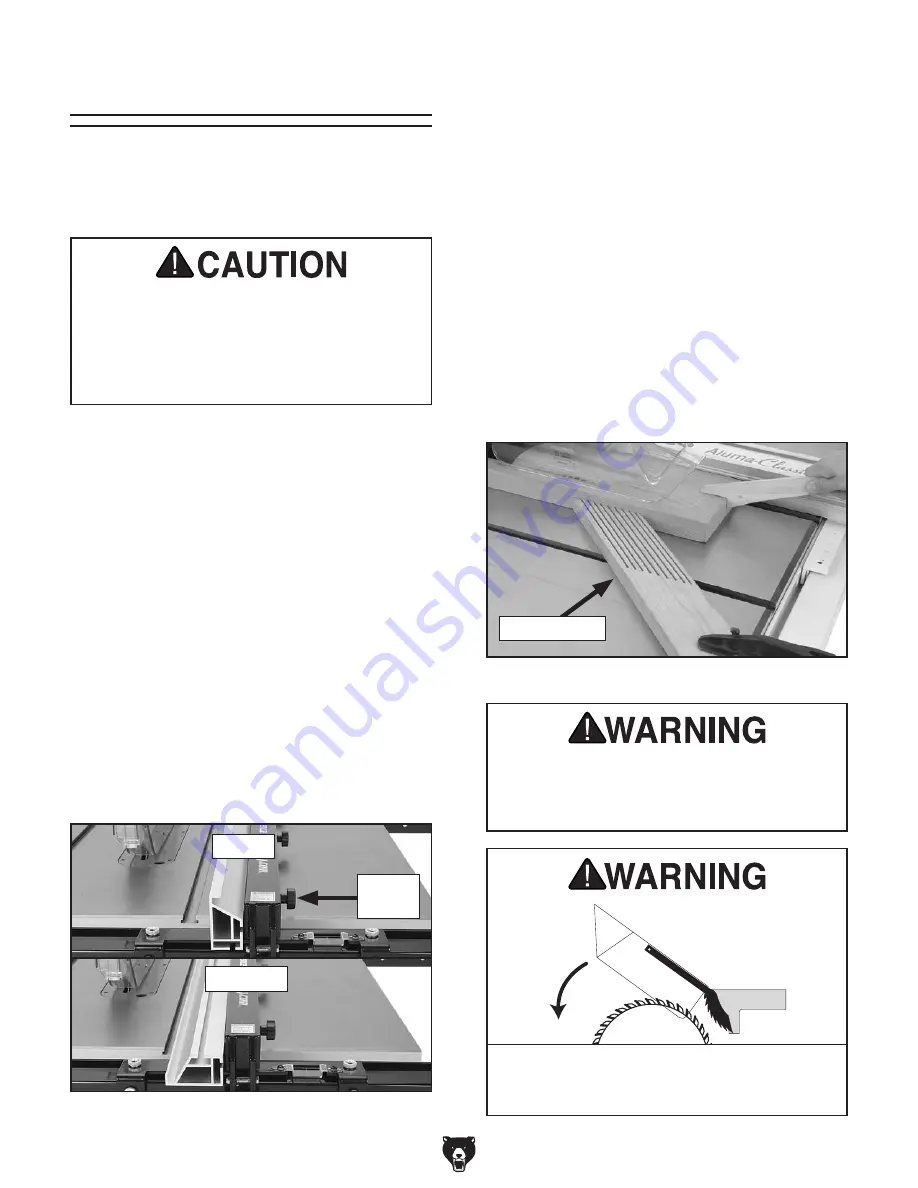

Figure 55. Typical ripping operation.

6. Set fence to desired width of cut on scale.

7. Adjust blade height so highest saw tooth pro-

trudes no more than

1

⁄

4

" above workpiece.

8. Set up safety devices such as featherboards

or other anti-kickback devices, making sure

no safety devices are contacting blade.

9. Plug saw into power source, turn it ON, and

allow it to reach full speed.

Note: Jointed edge of workpiece must slide

against fence during cutting operation.

10. Use push stick to feed workpiece through

saw blade, as shown in

Figure 55, until

workpiece is completely beyond saw blade.

To make a rip cut:

1. Review Preventing Kickback on Page 12

and take necessary precautions to reduce

likelihood of kickback.

2. If using natural wood, joint one long edge of

workpiece on a jointer.

3. DISCONNECT MACHINE FROM POWER!

4. Ensure that blade guard/spreader is installed.

5. Loosen fence knobs (see Figure 54), remove

rip fence, then re-install in vertical position for

thicker workpieces, or in horizontal position

for thinner workpieces and angled cuts where

blade is tilted over fence. Lift fence up and

tighten each fence knob.

"Ripping" means cutting with the grain of a natural

wood workpiece. In man-made materials such as

MDF or plywood, ripping means cutting length-

wise.

Ripping

Keep blade guard installed and in down

position. Failure to do this could result in

serious personal injury or death.

Turn saw OFF and allow blade to come to a

complete stop before removing cutoff piece.

Failure to follow this warning could result in

severe lacerations or amputation.

Serious injury can be caused by kickback.

Kickback is a high-speed ejection of stock

from table saw toward an operator. The

operator or bystanders may be struck by fly-

ing stock, or operator’s hands can be pulled

into blade during kickback.

Vertical

Horizontal

Figure 54. Rip fence positions.

Knob

(1 of 3)

Featherboard

Summary of Contents for Polar Bear G0833P

Page 92: ......