-30-

Model T32335 (Mfd. Since 11/20)

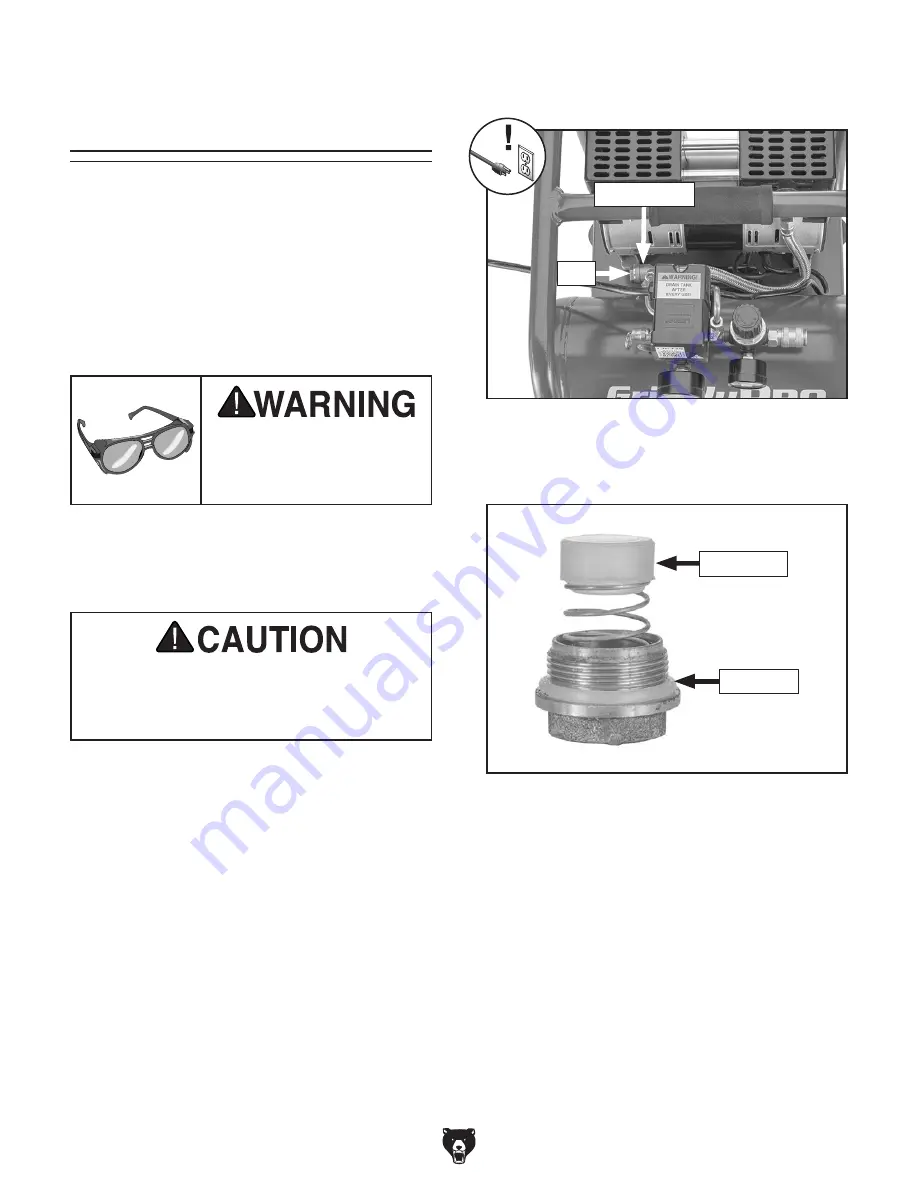

4. Inspect seal ring and diaphragm (see Figure

32) for damage and dirt.

Figure 32. Check valve components.

Seal Ring

Diaphragm

5. Replace any damaged parts and clean any

dirt from diaphragm and seal ring.

6. Re-install check valve/cap.

IMPORTANT: Make sure diaphragm presses

squarely against discharge line and exhaust

tube opening.

Note: Do not add thread sealant or Teflon

tape to cap threads. Seal ring provides suf-

ficient sealing.

Examining

Check Valve

The check valve pushes compressed air into the

tank and prevents it from flowing back toward

the pump. The diaphragm in the check valve can

become damaged, twisted, or dirty and cause

the valve to leak or prevent the compressor from

pressurizing.

Eye injury hazard! Always

wear safety glasses when

handling pressurized air

system.

Tool Needed

Qty

Wrench or Socket 19mm ................................... 1

To examine check valve:

1. DISCONNECT MACHINE FROM POWER!

Releasing air through drain valve can

be extremely loud. Protect hearing with

ANSI-approved hearing protection while

performing following step.

Figure 31. Location of check valve cap.

Check Valve

Cap

3. Remove cap shown in Figure 31 from check

valve.

2. Use safety relief valve to reduce tank pres-

sure to less than 10 PSI.

Summary of Contents for QUIET Series

Page 40: ......