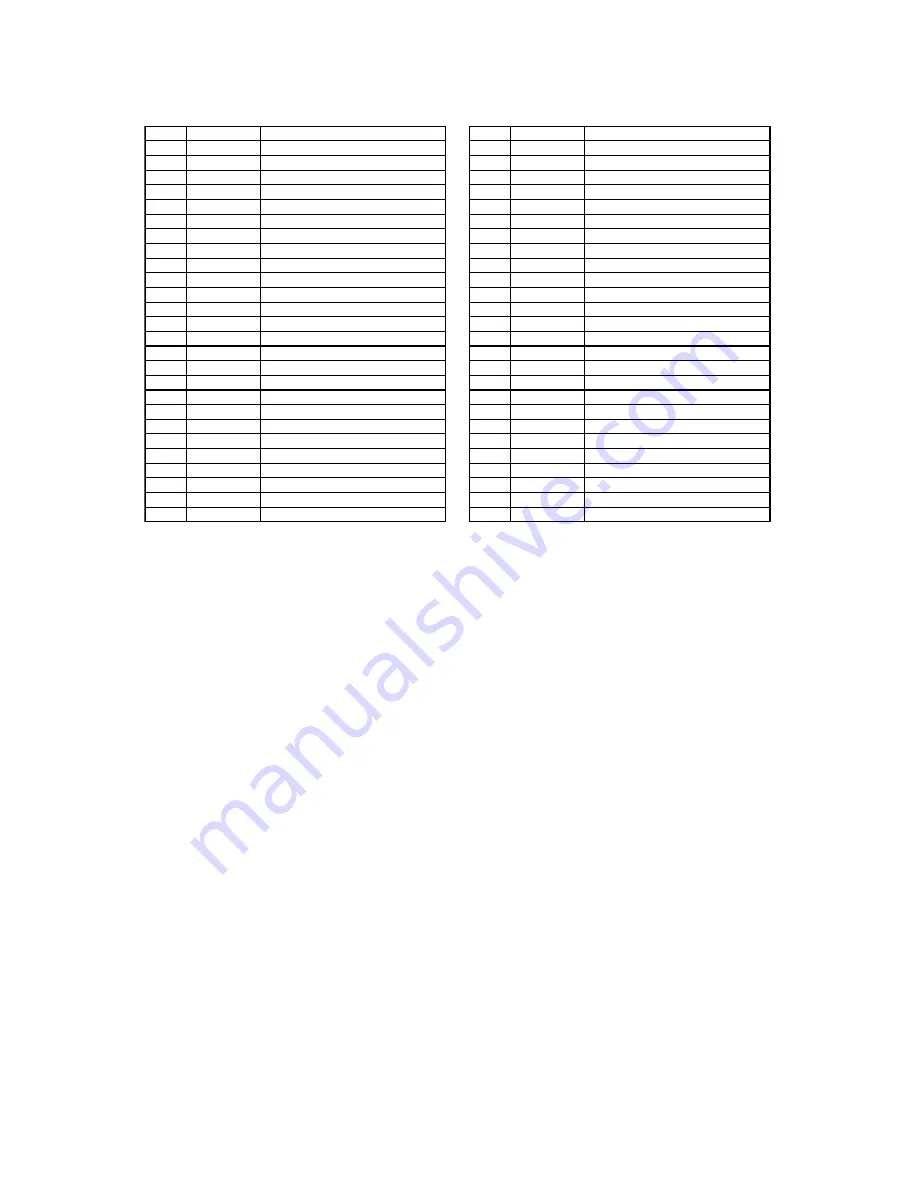

Model T10745

1

⁄

2

" x 18" Belt Sander

-15

-

main parts list

REF

PART #

DESCRIPTION

REF

PART #

DESCRIPTION

1

PT10745001

POWER CORD 18G 2W 72" 1-15

27

PT10745027

GEAR WHEEL PIN

2

PT10745002

POWER CORD SLEEVE

28

P608-2RS

BALL BEARING 608-2RS

3

PT10745003

ON/OFF SWITCH 250V 6A

29

PS07M

PHLP HD SCR M4-.7 X 8

4

PHTEK11M

TAP SCREW M3 X 8

30

PT10745030

DRIVE WHEEL COVER

5

PT10745005

VARIABLE SPEED CIRCUIT BOARD

31

PS52M

PHLP HD SCR M4-.7 X 20

6

PHTEK6M

TAP SCREW M4 X 16

32

PT10745032

DRIVE WHEEL COVER MOUNT

7

PT10745007

CABLE CLAMP

33

PS12M

PHLP HD SCR M3-.5 X 6

8

PT10745008

LEFT HOUSING

34

PT10745034

ARM BRACKET

9

PT10745009

MODEL NUMBER LABEL (L)

35

PN06M

HEX NUT M5-.8

10

PT10745010

REAR DRIVE WHEEL

36

PT10745036

ARM SUPPORT STAND

12

PT10745012

RIGHT HOUSING

37

PHTEK1M

TAP SCREW M3-.5 X 12

13

PT10745013

STATOR

38

PT10745038

MODEL NUMBER LABEL (R)

14

PT10745014

DAMPING RING

39

PT10745039

PIVOT KNOB M5-.8 X 20

15

P626ZZ

BALL BEARING 626ZZ

40

PT10745040

BELT TENSION BUTTON

16

PT10745016

ROTOR

40A

PT10745040A BELT TENSION BUTTON ASSEMBLY

16A

PT10745016A ROTOR ASSEMBLY

41

PT10745041

COMPRESSION SPRING

17

P626ZZ

BALL BEARING 626ZZ

42

PT10745042

BUTTON LATCH HOOK

18

PT10745018

PINION BUSHING PIN

43

PT10745043

COMPRESSION SPRING

19

PT10745019

PINION BUSHING

44

PT10745044

TENSION ARM

20

PT10745020

PINION

44A

PT10745044A TENSION ARM ASSEMBLY

21

PR04M

EXT RETAINING RING 6MM

45

PT10745045

MOUNTING PLATE ARM

22

PT10745022

CARBON BRUSH 2-PC SET

46

PT10745046

RIVET 3 X 10 FLAT HEAD ALUM

23

PT10745023

CARBON BRUSH HOLDER

47

P605ZZ

BALL BEARING 605ZZ

24

P608-2RS

BALL BEARING 608-2RS

48

PT10745048

FRONT BEARING SHAFT

25

PT10745025

GEAR WHEEL

49

PT10745049

FRONT ARM SUPPORT BRACKET

25A

PT10745025A GEAR WHEEL ASSEMBLY

50

PT10745050

RIVET 3 X 14 FLAT HEAD ALUM

26

PT10745026

OUTPUT SHAFT

51

PT10745051

SANDING BELT 1/2" X 18"

Summary of Contents for T10745

Page 18: ...Model T10745 1 2 x 18 Belt Sander 16...

Page 20: ......