Model t23103 (Mfg. 12/09 and later)

-15-

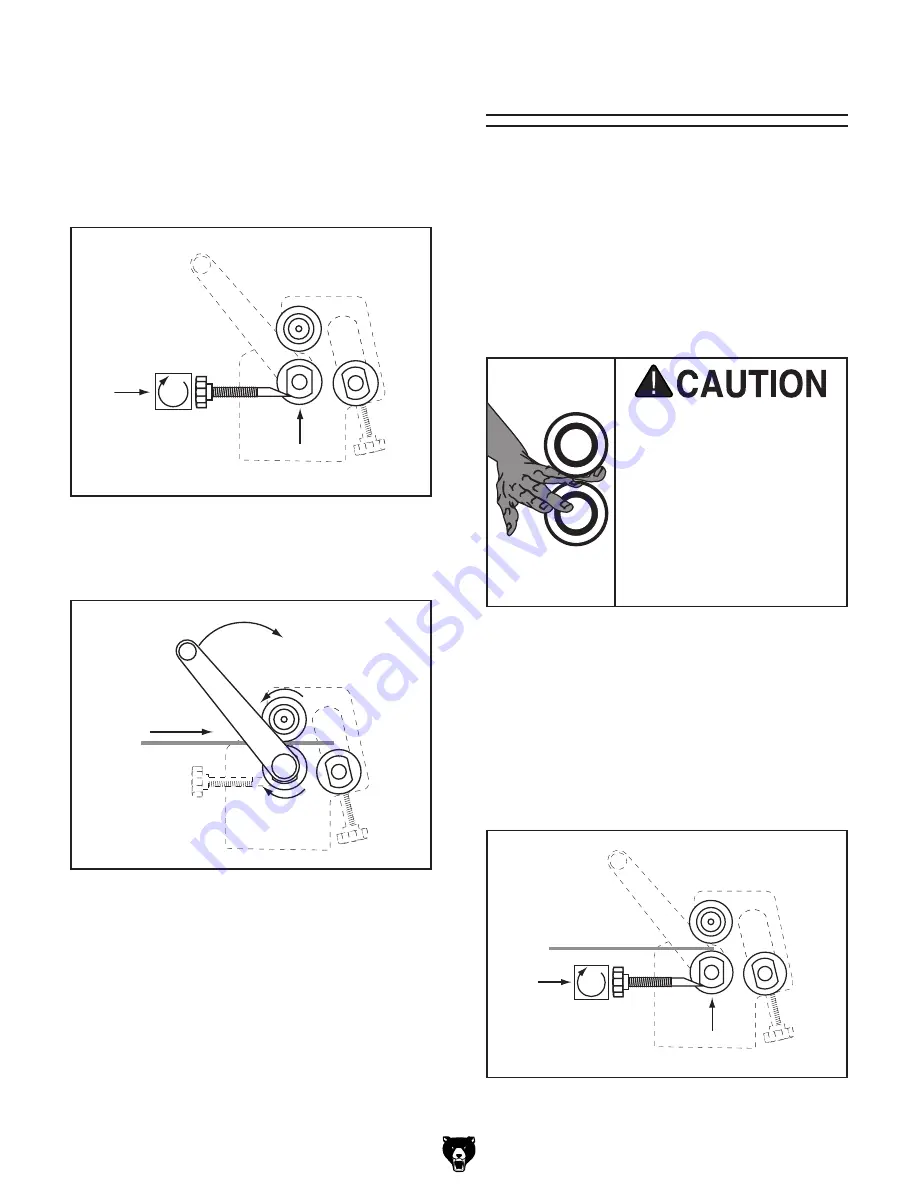

creating bends

the Model t23103 can easily create constant-

radius bends in sheet metal up to 20 gauge.

Note:

The method for creating a specific radius is

a trial-and-error process. Due to the many varia-

tions among metal workpieces, no single position-

ing will create the same curve on all materials. We

recommend using scrap pieces the same dimen-

sions and material as your final workpiece until the

desired curve is achieved.

2. remove the workpiece from between the

rollers, then raise the bottom roller slightly

by rotating each thickness adjustment knob

approximately

1

⁄

4

turn. also, make sure the

rear roller is lowered completely and will not

interfere with the workpiece as it exits the

machine (see

figure 15).

CW

figure 15. raising bottom roller

1

⁄

4

turn.

3. Feed the workpiece into the rollers while turn-

ing the crank (see

figure 16).

approximately

1

⁄

4

turn.

figure 16. Flat rolling the workpiece.

4. Continue processing the workpiece by repeat-

ing

Steps 2 and 3 until the desired results are

produced.

CW

figure 17. raising bottom roller.

To create a bend in a workpiece:

1. place the workpiece between the top and

bottom rollers, as shown in

figure 17. turn

the thickness adjust knobs to raise the bot-

tom roller until the workpiece is held snug

between the top and bottom rollers. Be sure

to turn the thickness adjust knobs equal

amounts.

The main rollers of this

machine present a pinch-

ing hazard. Make sure no

body part or clothing is

near the area between the

rollers. failure to follow this

warning may result in fin-

gers, hair, or clothing being

pulled into the machine,

causing personal injury.