t23110/t23111/t23112 lever Chain hoist

-6

-

section 4: maintenance

Follow regular maintenance to keep the

hoist in good working condition. to avoid

serious injury from hoist failure, never

attempt to repair a hoist that malfunc-

tions or becomes damaged. hoist repair

or service must be done by a qualified

technician only.

the hazard of an improper repair job is

that it could cause the hoist to fail and

unexpectedly drop the load, which could

crush or kill people below, or cause major

property damage. For this reason, we

strongly recommend replacing the hoist if

it malfunctions or becomes damaged.

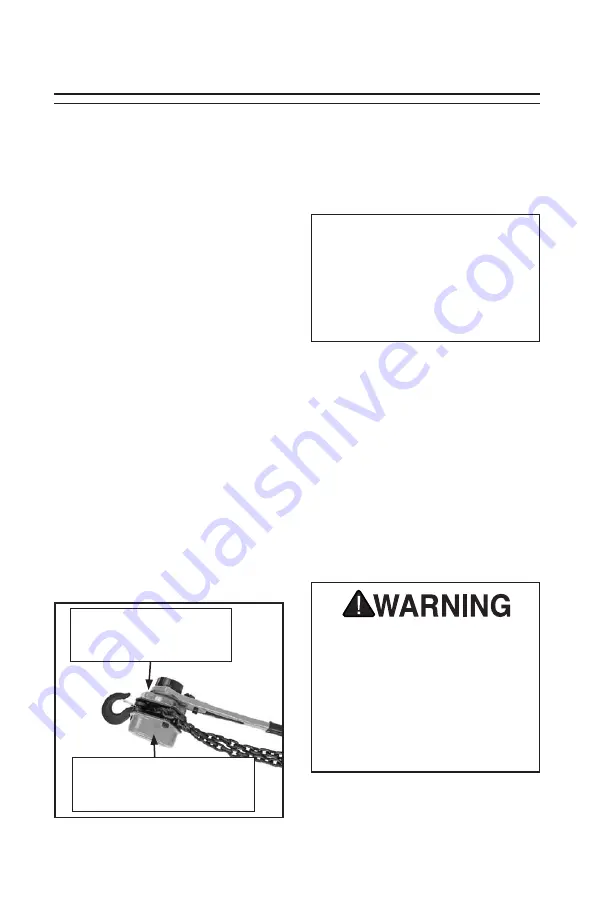

to avoid contaminating the friction brake

during maintenance, you must know the

difference between the gear cover and the

brake cover (see

figure 1).

the gear Cover will be removed during

routine maintenance. the Brake Cover

should only be removed by a qualified

technician; it encloses the friction brake

and protects it from exposure to contami-

nants, such as liquids or lubrication, that

will cause the brake to fail under load.

cleaning

to prevent the chains from jamming, clean

away dirt and debris from the outside of

the hoist housing and the chains.

NOTICE

do not submerge the hoist housing

in liquid of any kind or allow liquid

to enter the brake cover during

cleaning, or the braking mechanism

may fail to work properly.

chain lubrication

When the chains are clean and dry, apply

a thin coat of light machine oil to the links

with an oiled shop rag to ensure smooth

movement and prevent corrosion.

storage

Before storing the hoist, clean and lubri-

cate the chains. always store the hoist in

a clean, dry, and protected area to prevent

corrosion or damage.

a malfunctioning or damaged hoist

may drop its load and crush or kill

people below, or cause major property

damage. to reduce this risk, observe

all care and maintenance noted in

the manual. if hoist malfunctions

or becomes damaged, replace it, or

have it serviced by a qualified service

technician.

figure 1. hoist housing cover

identification.

gear cover

Can be removed by operator for

gear lubrication.

brake cover

May be removed only by a

qualified technician.