For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

MODEL T25251

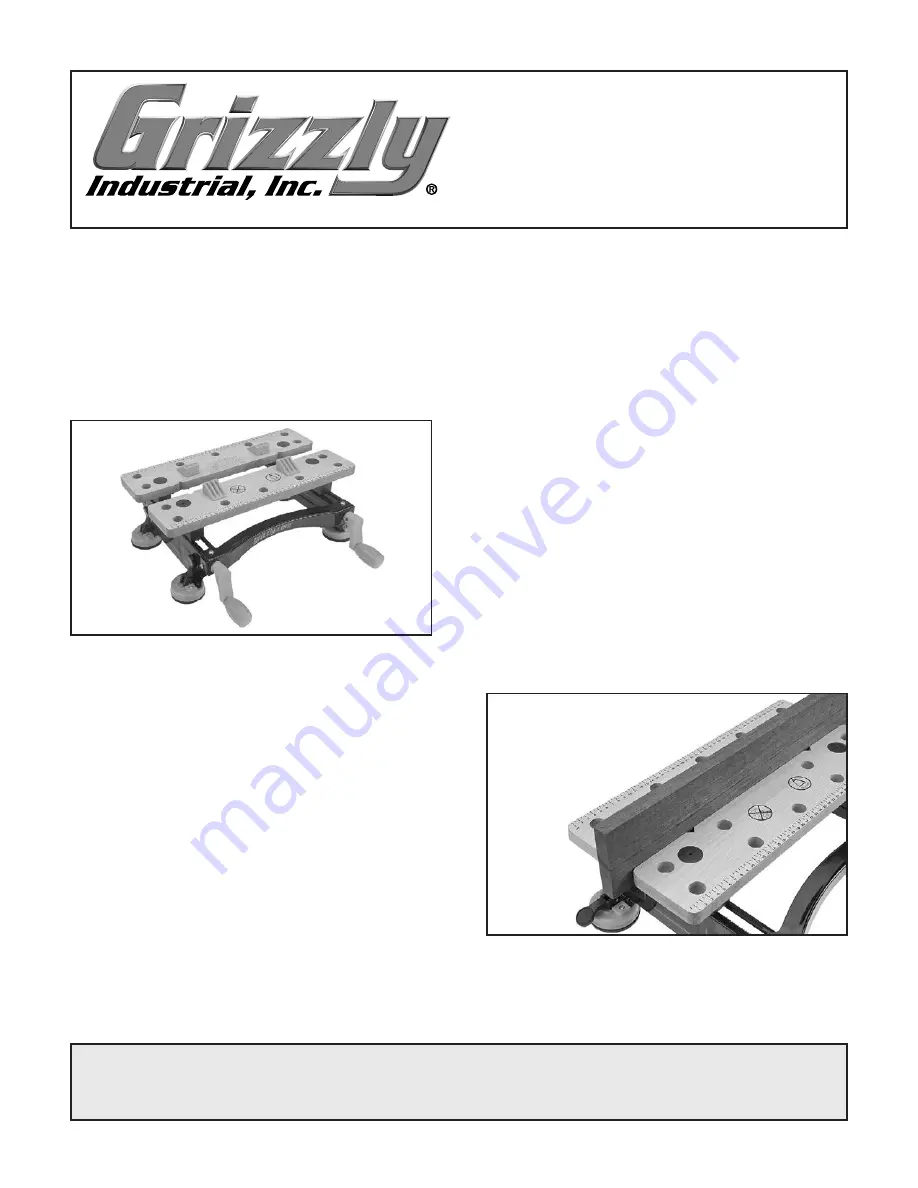

MINI WORKBENCH

INSTRUCTIONS

COPYRIGHT © APRIL, 2014 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#MN16530 PRINTED IN CHINA

This mini workbench features independently

adjustable hand screws for irregular clamping

with the table jaws, four pivoting clamp dogs for

gripping flat work, and non-marring suction cup

feet for securing the mini workbench to smooth,

flat surfaces.

Introduction

Operation

Figure 1. Model T25251 Mini Workbench.

Specifications

Weight .........................................................8 lbs.

Dimensions .........................18"W x 16

1

⁄

2

"D x 6"H

Work Surface .................................... 7

7

⁄

8

" x 17

3

⁄

4

"

Clamping Capacity w/Table Jaws ....................3"

Clamping Capacity w/Clamp Dogs ................8

1

⁄

8

"

Maximum Weight Capacity........................22 lbs.

Assembly

The Model T25251 Mini Workbench is completely

assembled. Insert the four clamp dogs into the

tables to accommodate different shapes and

sizes of work material.

Clamping Workpiece Between Table Jaws

The mini workbench can be used as a vise to

secure materials between the table jaws.

To clamp workpiece between table jaws:

1. Turn hand screws counterclockwise to open

jaws widely enough to insert workpiece.

2. Place workpiece between table jaws.

3. Rotate hand screws clockwise to tighten jaws

and secure workpiece (see

Figure 2).

Note: The hand screws on the mini work-

bench turn independently of one another.

By holding one hand screw stationary and

turning the other, the table opening can

be skewed (like a "V") to hold odd-shaped

objects.

Figure 2. Workpiece clamped between table

jaws.