27

Electrical System

18 690 01 Rev. C

KohlerEngines.com

Carbon Fouled

Soft, sooty, black deposits indicate incomplete

combustion caused by a restricted air cleaner, over rich

carburetion, weak ignition, or poor compression.

Overheated

Chalky, white deposits indicate very high combustion

temperatures. This condition is usually accompanied

by excessive gap erosion. Lean carburetor settings,

an intake air leak, or incorrect spark timing are normal

causes for high combustion temperatures.

BATTERY

A 12 volt battery (not furnished) with a minimum current

rating of 230 cold cranking amps/18 amp hours should

be suf

fi

cient for cranking most electric start engine

models. Actual cold cranking requirement depends

on engine size, application and starting temperatures.

Cranking requirements increase as temperatures

decrease and battery capacity shrinks. Refer to

equipment's operating instructions for speci

fi

c battery

requirements.

If battery charge is insuf

fi

cient to turn over engine,

recharge battery.

Battery Maintenance

Regular maintenance is necessary to prolong battery

life.

Battery Test

To test battery, follow manufacturer's instructions.

ELECTRONIC IGNITION SYSTEM

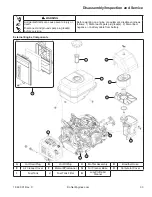

Inductive Discharge Ignition System Components

A

C

D

E

F

G

H

I

J

B

A

Kill Switch/Off Position

of Key Switch

B

Air Gap 0.254 mm

(0.010 in.)

C

Flywheel

D

Magnet

E

Ignition Module

F

Spark Plug

G

Kill Terminal

H

Lamination

I

Spark Plug Terminal

J

Spark Plug Boot

These engines are equipped with a dependable

magneto breakerless ignition. In such a system,

electrical energy is generated by cutting of magnetic

fl

ux

lines generated from ignition magnet on engine

fl

ywheel

via prescribed air gap as it passes ignition module.

This energy is transferred through ignition module

laminations and is then converted in module electronics

and stored in module primary coil, as a current. Stored

energy is transferred at correct moment by triggering a

semiconductor switch inside module. Electrical break

by switch initiates energy transfer by causing collapse

of magnetic

fi

eld at coil primary. This includes a voltage

at coil primary that is ampli

fi

ed via transformer action at

coil secondary. Amplitude of voltage at coil secondary

is suf

fi

cient to jump gap at spark plug, igniting fuel air

mixture in gap and initiating combustion. Note that by

design, these modules only will provide proper function if

mounted in correct orientation.

This ignition system is designed to be trouble free for

life of engine. Other than periodically checking/replacing

spark plugs, no maintenance or timing adjustments

are necessary or possible. Mechanical systems do

occasionally fail or break down. Refer to Troubleshooting

to determine root of a reported problem.

Reported ignition problems are most often due to poor

connections. Before beginning test procedure, check

all external wiring. Be certain all ignition-related wires

are connected, including spark plug leads. Be certain all

terminal connections

fi

t snugly. Make sure ignition switch

is in run position.

Summary of Contents for T27710

Page 40: ...38 Model T27710 Mfd Since 04 16...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 115: ...53 18 690 01 Rev C KohlerEngines com...

Page 116: ...54 KohlerEngines com 18 690 01 Rev C...

Page 117: ...55 18 690 01 Rev C KohlerEngines com...

Page 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...