32

Starter System

KohlerEngines.com

18 690 01 Rev. C

RETRACTABLE STARTERS

WARNING

Retractable starters contain a powerful, recoil spring that is

under tension. Always wear safety goggles when servicing

retractable starters and carefully follow instructions in

Retractable Starter for relieving spring tension.

Uncoiling Spring can cause severe injury.

Wear safety goggles or face protection when

servicing retractable starter.

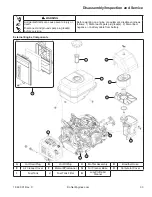

Retractable Starter Components

A

B

A

Kit, Pawl Repair

B

Kit, Starter Rope with Handle

Remove Starter

1. Remove screws securing starter to blower housing.

2. Remove starter assembly.

Rope Replacement

NOTE: Do not allow pulley/spring to unwind. Enlist aid

of a helper if necessary.

Rope can be replaced without complete starter

disassembly.

1. Remove starter assembly from engine.

2. Pull rope out approximately 12 in. and tie a

temporary (slip) knot in it to keep it from retracting

into starter.

3. Pull knot end out of handle, untie knot, and slide

handle off.

4. Hold

pulley

fi

rmly and untie slipknot. Allow pulley to

rotate slowly as spring tension is released.

5. When all spring tension on starter pulley is released,

remove rope from pulley.

6. Tie a double left-hand knot in one end of new rope.

7. Rotate pulley counterclockwise to pre-tension spring

(approximately 4 full turns of pulley).

8. Continue rotating pulley counterclockwise until rope

hole in pulley is aligned with rope guide bushing of

starter housing.

9. Insert unknotted end of new rope through rope hole

in starter pulley and rope guide bushing of housing.

10. Tie a slipknot approximately 12 in. from free end of

rope. Hold pulley

fi

rmly and allow it to rotate slowly

until slipknot reaches guide bushing of housing.

11. Insert starter rope through starter handle and tie a

double, left-hand knot at end of starter rope. Insert

knot into hole in handle.

12. Untie slip knot and pull on starter handle until starter

rope is fully extended. Slowly retract starter rope into

starter assembly. If recoil spring is properly

tensioned, starter rope will retract fully and starter

handle will stop against starter housing.

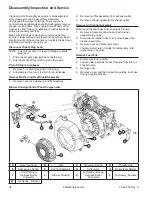

Pawls (dogs) Replacement

1. Install a clamp to hold pulley in starter housing and

prevent it from rotating.

2. Unscrew center screw and lift off drive plate.

3. Note positions of pawls and pawl springs before

removing. Remove parts from pulley.

4. Install pawl springs and pawls into pawl slots of

pulley. All parts must by dry.

5. Position drive plate over pawls, aligning actuating

slots in place with raised sections on each drive

pawl. Torque center screw to 5-6 N·m (44-54 in. lb.).

6. Remove clamp and pull starter rope out part way to

check operation of pawls.

Install Starter

1. Install retractable starter onto blower housing leaving

screws slightly loose.

2. Pull starter handle out until pawls engage in drive

cup. Hold handle in this position and tighten screws

securely.

Summary of Contents for T27710

Page 40: ...38 Model T27710 Mfd Since 04 16...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 115: ...53 18 690 01 Rev C KohlerEngines com...

Page 116: ...54 KohlerEngines com 18 690 01 Rev C...

Page 117: ...55 18 690 01 Rev C KohlerEngines com...

Page 118: ...56 KohlerEngines com 18 690 01 Rev C 2015 by Kohler Co All rights reserved...