Model T28325 (Mfd. Since 1/18)

-21-

SECTION 5: MAINTENANCE

For optimum performance from this machine, this

maintenance schedule must be strictly followed.

Ongoing

To maintain a low risk of injury and proper machine

operation, if you ever observe any of the items

below, stop operating the machine immediately

and fix the problem before continuing operations:

•

Loose mounting bolts.

•

Worn or damaged clamping fingers or bend-

ing blocks.

•

Any other unsafe condition.

Daily

•

Lubricate clamping leaf slide shafts.

•

Lubricate bending leaf pivot bushings.

Weekly Maintenance

•

Lubricate bending leaf cam.

•

Lubricate setback shafts.

Schedule

Cleaning &

Protecting

Use a brush to clear away any metal debris and

dust from the clamping fingers, clamping base,

and bending blocks.

Use a shop rag to carefully apply a thin coat of

quality metal protectant (see

Page 18 for offerings

from Grizzly) to all exposed unpainted surfaces to

prevent corrosion.

Lubrication

Clamping Leaf Slide Shafts

Oil Type ................ SB1365 or ISO 32 Equivalent

Oil Amount ..................................... 1 or 2 Squirts

Lubrication Frequency ................................. Daily

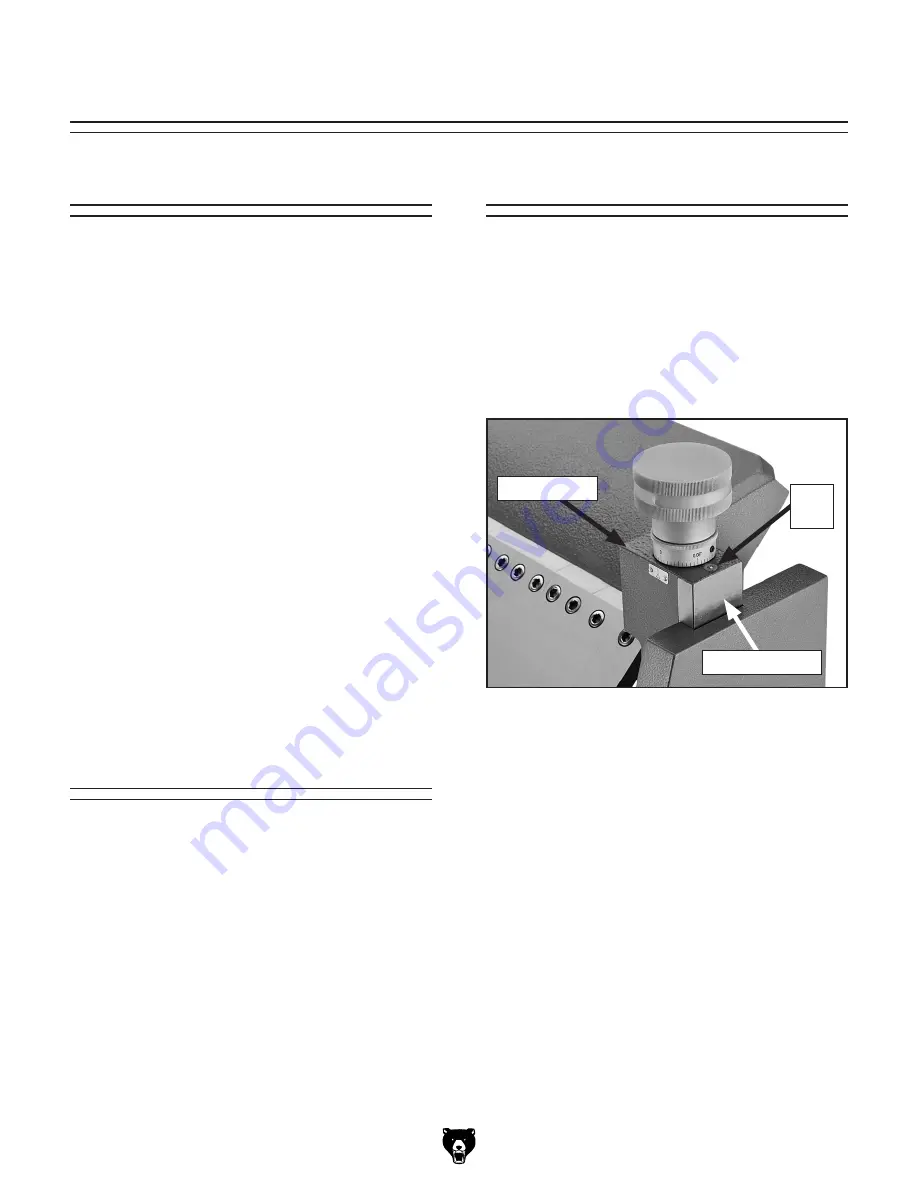

The slide shaft ball oilers (see

Figure 25) provide

lubrication to the sliding surfaces between the

shafts and the frame.

Figure 25. Clamping leaf slide shaft ball oiler.

Ball

Oiler

Sliding Surface

Only lubricate these ball oilers with a pump-type

oil can that has a plastic or rubberized cone tip.

Do not use oil cans with a metal needle or lance

tip, as they can push the ball too far into the oiler,

break the spring seat, and lodge the ball in the oil

galley.

When lubricating the ball oilers, first clean the out-

side surface to remove any dust or grime. Push

the tip of the oil can nozzle against the ball oiler

to create a hydraulic seal, then pump the oil can

once or twice to add oil.

Slide Shaft

Summary of Contents for T28325

Page 32: ......