Model T30945 (Mfd. Since 12/19)

-17-

Test Run

Once assembly is complete, test run the machine

to ensure it is properly connected to power and

safety components are functioning correctly.

If you find an unusual problem during the test run,

immediately stop the machine, disconnect it from

power, and fix the problem BEFORE operating the

machine again. The

Troubleshooting table in the

SERVICE section of this manual can help.

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine

may result in malfunction or unexpect-

ed results that can lead to serious injury,

death, or machine/property damage.

Serious injury or death can result from

using this machine BEFORE understanding

its controls and related safety information.

DO NOT operate, or allow others to operate,

machine until the information is understood.

To test run machine:

1. Clear all setup tools away from machine.

2. Connect machine to power supply.

3. Turn machine ON by pulling switch paddle up,

verify motor operation, and then turn machine

OFF by pushing switch paddle down.

The motor should run smoothly and without

unusual problems or noises.

The Test Run consists of verifying the following: 1)

The motor powers up and runs correctly.

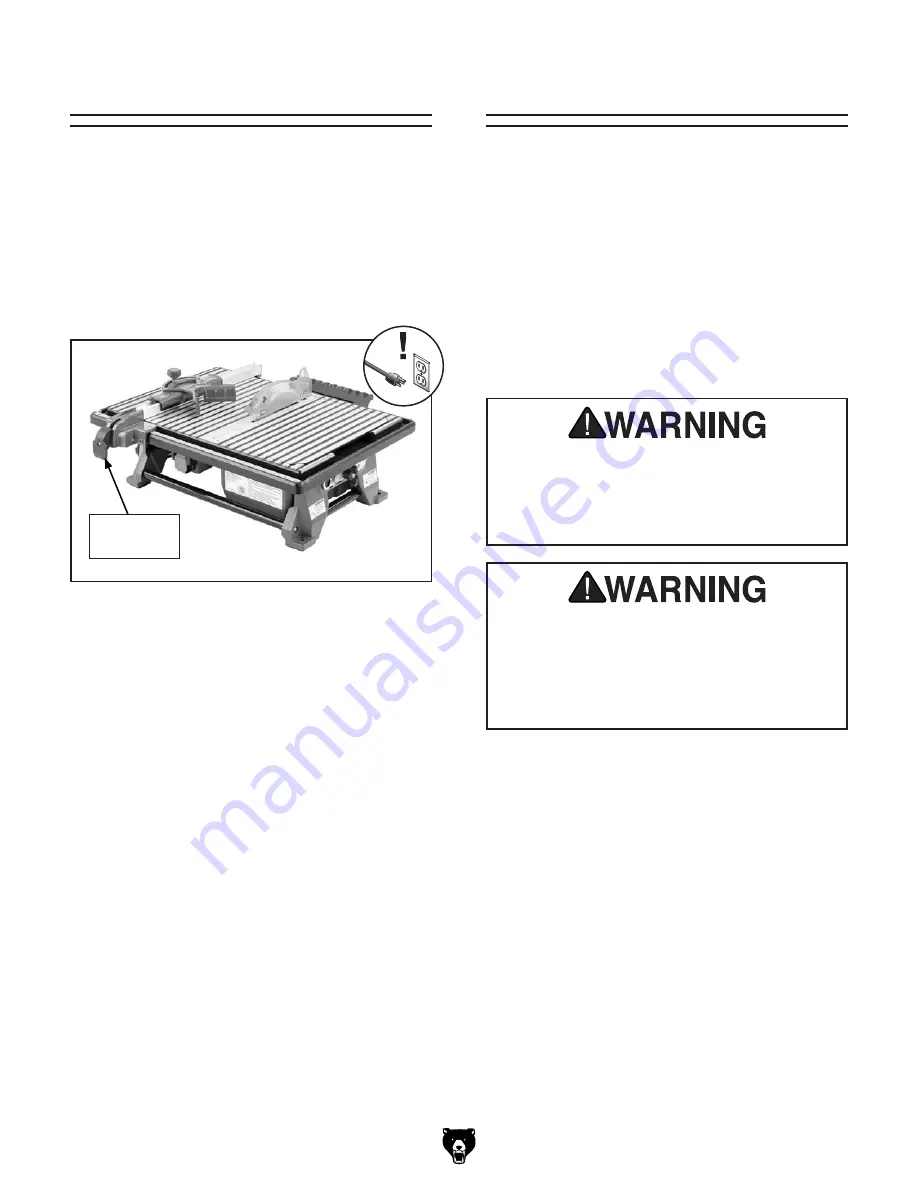

Lifting & Moving

To lift and move machine:

1. DISCONNECT MACHINE FROM POWER!

2. Secure rip fence position with rip fence lock

lever (see

Figure 17).

The Model T30945 is light enough for one person

to lift and move a short distance.

Figure 17. Rip fence lock location.

Rip Fence

Lock Lever

3. Lift machine by table edges and move to pre-

pared location.

Summary of Contents for T30945

Page 40: ......