To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

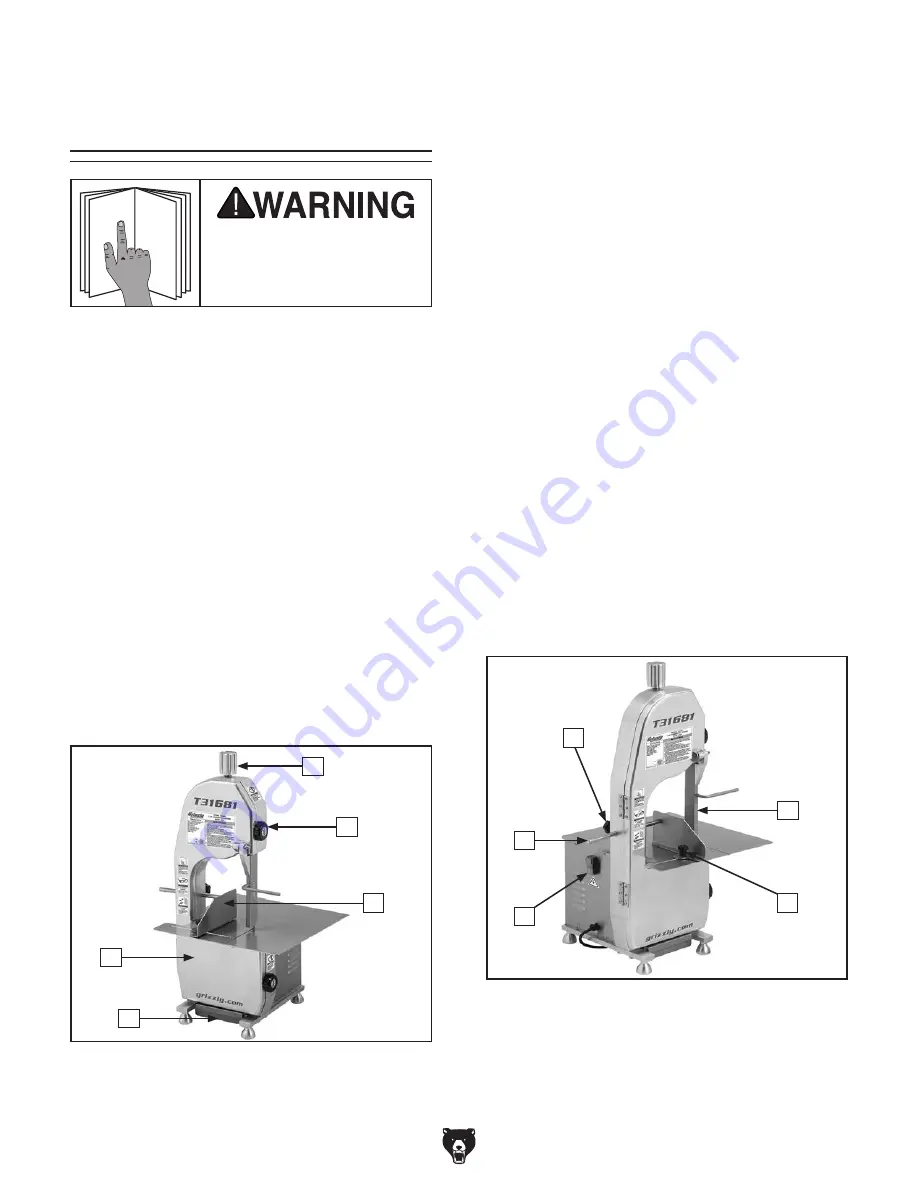

Figure 1. Front components.

Figure 2. Rear components.

-4-

Model T31681 (Mfd. Since 12/19)

Controls &

Components

A. Blade Tension Knob: Adjusts blade tension.

Turn clockwise to increase tension. Turn

counterclockwise to reduce tension.

B. Wheel Cover Knob: Locks and unlocks

wheel cover. Turn clockwise to unlock wheel

cover. Turn counterclockwise to lock wheel

cover.

C. Fence: Supports workpiece when making

straight cuts. Distance from blade determines

width of cut. Removable for cleaning and

sanitizing.

D. Scrap Tray: Collects scraps attached to

blade after cut is made. Removable for clean-

ing and sanitizing.

E. Wheel Cover: Covers saw blade and upper

and lower wheels. Disconnects power to

motor when opened.

F. Support Rod Knob: Locks and unlocks

fence support rod. Turn clockwise to lock

support rod. Turn counterclockwise to unlock

support rod.

G. Meat Pusher: Pushes meat for safe and

consistently-sized cuts. Removable for clean-

ing and sanitizing.

H. Fence Lock Knob: Locks and unlocks fence.

Turn clockwise to lock fence. Turn counter-

clockwise to unlock fence.

I. On/Off Push Button Switch: Starts and

stops the motor. Push the green "

I" button to

turn the motor

ON. Push the red "O" button to

turn the motor

OFF.

J. Fence Support Rod: Adjusts fence parallel-

ism and braces fence throughout length of

cut.

A

E

B

D

C

F

J

G

I

H

Refer to the following figures and descriptions to

become familiar with the basic controls and com-

ponents of this machine. Understanding these

items and how they work will help you understand

the rest of the manual and minimize your risk of

injury when operating this machine.

Summary of Contents for T31681

Page 36: ......