-12-

Model T32002 (Mfd. Since 02/20)

Additional Safety for Buffers

CORRECT ACCESSORIES AND USE. Never

install a grinding wheel on buffing side of machine.

Buffer is only designed for buffing and polishing.

Never exceed maximum speed listed on each

buffing/polishing wheel.

HAND/WHEEL CONTACT. DO NOT allow hands

to contact buffing wheel. Abrasive accessories

can remove skin fast. Keep firm grip on workpiece

and keep hands at a safe distance away when

buffing. If workpiece is small or difficult to hold,

use a workpiece holding fixture.

WORKPIECE SELECTION. Always inspect con-

dition of workpiece. DO NOT buff pieces with

loose knots, large splinters, sharp edges, and DO

NOT buff knives, cable, chain or other potentially

dangerous objects that may be grabbed by buff-

ing wheel and thrown at operator.

WORKPIECE FEED. Allow wheel to reach full

speed, then slowly ease workpiece into wheel,

holding it in front of and slightly below wheel

center. Do not place workpiece on top or sides

of wheel and do not place edge or corner of

workpiece against wheel, or jam it against wheel.

Workpiece may eject toward operator or be torn

from hands, causing serious personal injury.

AVOIDING ENTANGLEMENT. Becoming entan-

gled in moving parts can cause severe injury or

death. Keep all guards and covers in place; DO

NOT wear loose clothing, gloves, or jewelry; and

tie back long hair.

EYE, FACE, & LUNG PROTECTION. Always

wear eye protection or face shield and heavy

leather apron when operating buffer. Wear dust

mask to protect lungs from microscopic par-

ticulates as they may cause allergies or long-term

respiratory health problems.

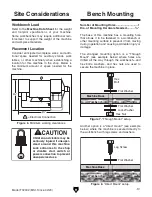

MOUNTING TO BENCH/STAND. An unsecured

machine may become dangerously out of control

during operation. FIRMLY secure machine to

bench/stand before use.

WORKPIECE CONTROL. If you cannot hold

small workpieces securely, do not buff them with

this machine. Secure workpiece with clamps or

jigs or use different machine.

AVOIDING KICKBACK. Avoid kickback by buff-

ing in accordance with wheel rotation. Always buff

on downward side of wheel and keep wheel cover

in place. Avoid buffing with excessive force.

DISCONNECT POWER WHEN SERVICING.

Disconnect machine from power and allow wheel

to come to complete stop before service, main-

tenance, or adjustments. Avoid pulling cord-con-

nected machinery from cord–instead, grasp plug

when disconnecting from power.

OPERATOR POSITION. DO NOT stand directly

in front of

buffer wheel when turning machine ON,

or when buffing. Do not buff material at rear of

machine.

Entanglement/amputation injuries can occur from being caught in moving parts or in-running

pinch points. Rotating buffing wheel can easily remove skin. To minimize risk of getting hurt or

killed, anyone operating machine MUST completely heed hazards and warnings below.

Summary of Contents for T32002

Page 36: ......