-20-

Model T32002 (Mfd. Since 02/20)

Workpiece

Inspection

Electrical system is not waterproof. DO NOT

use this grinder with a liquid cooling system

required for wet grinding wheel operations.

Ignoring this warning can lead to electrocu-

tion or machine damage.

Some workpieces are not suitable for grinding on

a bench grinder.

Before grinding, inspect all

workpieces for the following:

•

Hard Workpiece: Workpieces that are made

of stone, carbide, stainless steel, ceramics,

glass, or have hardened welds will wear out

most general-grade grinding wheels quickly.

If hard materials are to be ground, you must

install the correct type of grinding wheel.

•

Soft Workpiece: Workpieces that are made

of aluminum, brass, lead, and other nonfer-

rous metals will load up in the grinding wheel

and render the abrasive useless. Grinding

wood, plastics, rubber, fiberglass, or other

soft materials can also cause the same

problem and lead to the wheel overheating

and possibly bursting during use if ignored.

To restore a loaded grinding wheel surface,

redress with a dressing tool.

•

Flexible/Unstable Workpiece: Grinding on

the side or the ends of cable, chain, or round

workpieces creates the hazard of workpiece

twist or grab, leading to entanglement with

the wheel or shaft. This hazard must be

avoided.

•

Loose Parts: Make sure that the workpiece

is free of any parts like springs, pins, balls,

or other components that may loosen or dis-

lodge during grinding, and hit the operator.

•

Strength: Make sure that the workpiece is

strong enough to be ground. Should it break,

the broken piece may dig into the wheel and

cause kickback or severe injury.

Selecting

Grinding Wheel

The Model T32002 only accepts Type 1 wheels

with a

3

⁄

8

" bore.

Aluminum oxide and silicon carbide wheels are

marked in a somewhat uniform manner by all

the major manufacturers. Understanding these

markings will help you understand the capabilities

of various wheels. Always refer to the manufac-

turer’s grinding recommendations when selecting

a wheel for your project.

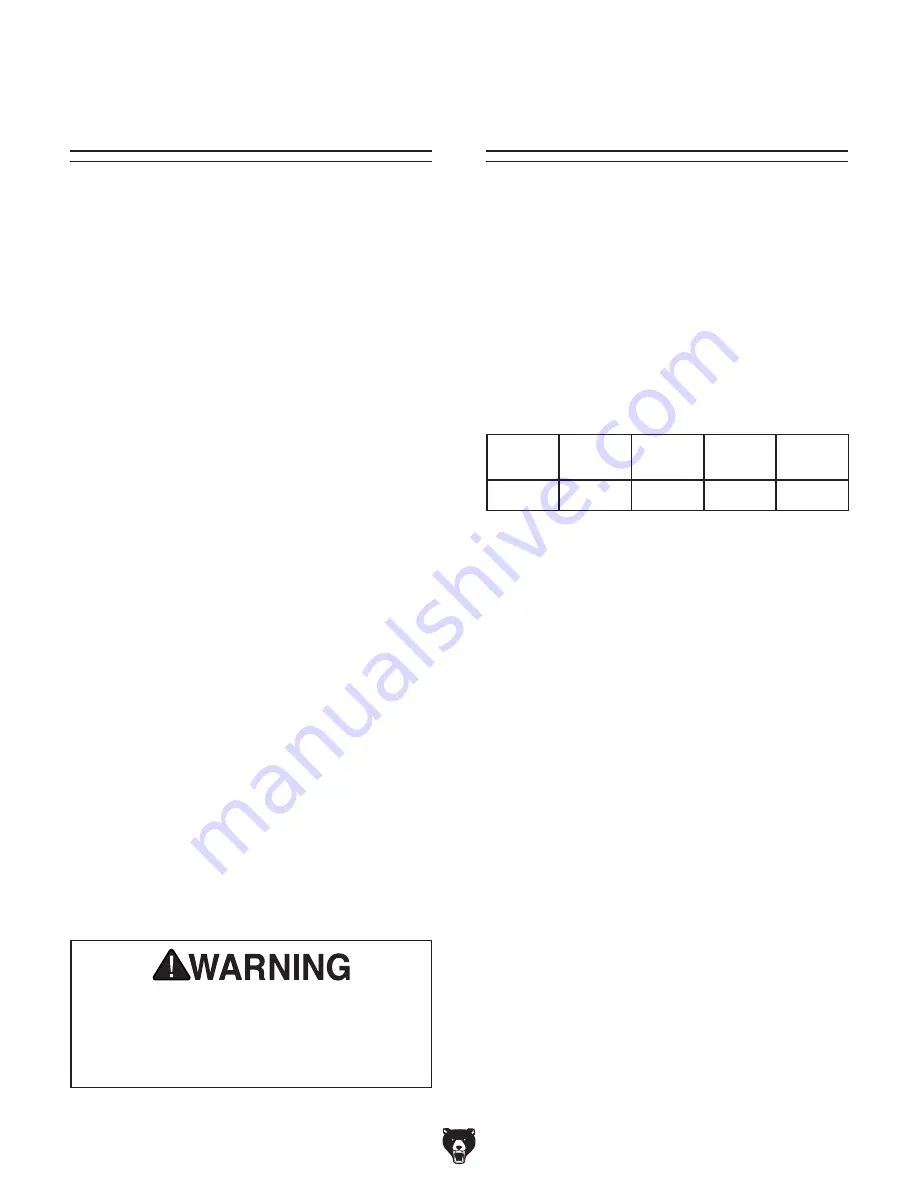

The basic format for wheel numbering is:

Prefix

Abrasive

Type

Grit Size Grade

Bond

Type

1

A

60

L

V

The

Prefix is the manufacturer’s designation for a

particular wheel type (eg. Type 1 wheels).

The most common

Abrasive Types used are A

for Aluminum Oxide, C for Silicon Carbide, and

occasionally SG for Seeded Gel.

The

Grit Size is a number that refers to the size

of the abrasive grain in the wheel. The lower the

number, the coarser the wheel. Ten is a very

coarse wheel for roughing and 220 is usually the

upper range for fine finish work.

Grade is an indication of the hardness of the

wheel—“A” being the softest and “Z” being the

hardest.

Bond Type refers to the type of bonding material

used to hold the abrasive material. Most general

purpose wheels will have a “V” indicating Vitrified

Clay is used. Vitrified Clay provides high strength

and good porosity. The other common bond type

is “B” for resin where synthetic resins are used.

These are used to grind cemented carbide and

ceramic materials.

Note: There may be other numbers inserted that

have meaning for a particular type of wheel. Refer

to the manufacturer’s technical data for a com-

plete explanation.

Summary of Contents for T32002

Page 36: ......