-34-

Model T32002 (Mfd. Since 02/20)

BUY PARTS ONLINE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

1

PT32002001

HEX NUT M8-1.25 LH

17

PT32002017

MOTOR COVER (RH)

2

PT32002002

BUFFING WHEEL 3 X 3/4 X 3/8 NYLON

18

PT32002018

SAFETY SHIELD MOUNTING BRACKET

3

PT32002003

WHEEL FLANGE

19

PT32002019

STATOR

4

PT32002004

SPACER 10 X 14 X 4

20

PT32002020

STATOR CLAMP

5

PT32002005

BALL BEARING 6200ZZ

21

PT32002021

SPACER 4.4 X 8.1 X 15

6

PT32002006

EXT RETAINING RING 10MM

22

PT32002022

BRUSH HOLDER

7

PT32002007

ROTOR

23

PT32002023

SPACER 4.4 X 8.1 X 8

8

PT32002008

ARMATURE

24

PT32002024

BRUSH CAP

9

PT32002009

MOTOR FAN

25

PT32002025

COMPRESSION SPRING 0.25 X 4 X 18

10

PT32002010

BALL BEARING 6200ZZ

26

PT32002026

CARBON BRUSH (1 PAIR)

11

PT32002011

GRINDING WHEEL 3 X 3/4 X 3/8 100-GRIT

27

PT32002027

MOTOR HOUSING

12

PT32002012

HEX NUT M8-1.25

27A PT32002027A MOTOR ASSEMBLY

13

PT32002013

STANDOFF-HEX MF M8-1.25

28

PT32002028

MOTOR COVER (LH)

14

PT32002014

GRINDING WHEEL COVER

29

PT32002029

CIRCUIT BOARD XD-1110

15

PT32002015

HEX NUT M4-.7

30

PT32002030

BASE STAND

16

PT32002016

STUD-DE M4-.7 X 100, 20

31

PT32002031

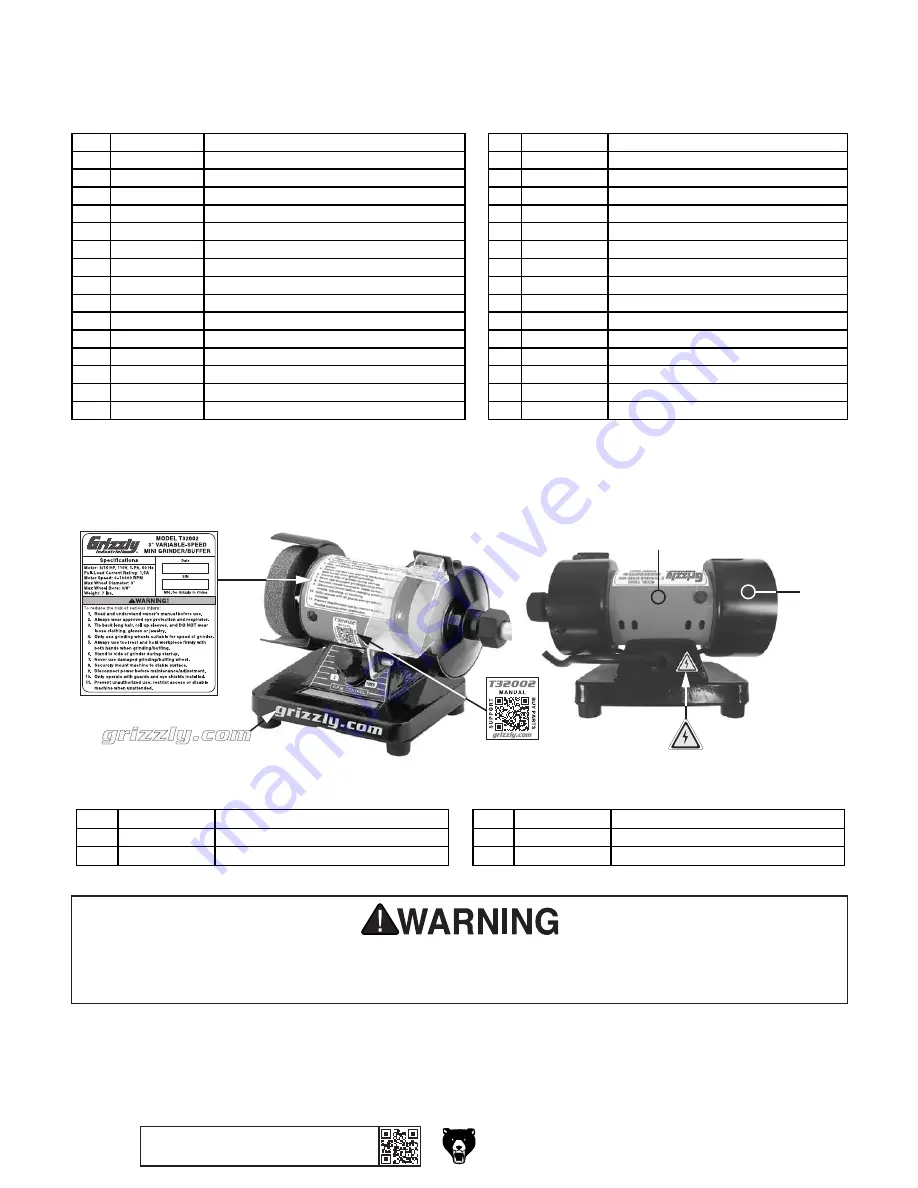

VARIABLE-SPEED DIAL K17-1

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

32

PT32002032

ROTATING FLEXIBLE SHAFT

49

PT32002049

O-RING 14 X 1.5

33

PT32002033

ROTARY SHAFT ADAPTER

50

PT32002050

WRENCH 9MM OPEN-END

34

PT32002034

POWER CORD 18G 3W 72" 5-15P

51

PT32002051

BASE

35

PT32002035

COMPRESSION SPRING 1 X 13 X 95

52

PT32002052

INT TOOTH WASHER 4MM

37

PT32002037

HEX NUT M20-2.5 PLASTIC

53

PT32002053

FLAT WASHER 4MM

38

PT32002038

TOOL REST

54

PT32002054

PHLP HD SCR M5-.8 X 20

39

PT32002039

ROTARY SHAFT HOSE

55

PT32002055

LOCK WASHER 5MM

40

PT32002040

COMPRESSION SPRING 1 X 13 X 95

56

PT32002056

RUBBER FOOT

41

PT32002041

ROTARY SHAFT BODY

57

PT32002057

PHLP HD SCR M4-.7 X 6

42

PT32002042

BALL BEARING 686ZZ

58

PT32002058

PHLP HD SCR M5-.8 X 6

43

PT32002043

SPINDLE SPACER 6ID

59

PT32002059

PHLP HD SCR M4-.7 X 30

44

PT32002044

BALL BEARING 686ZZ

60

PT32002060

LOCK NUT M4-.7

45

PT32002045

SPINDLE

61

PT32002061

SPEED DIAL HEX NUT M9

46

PT32002046

COLLET

62

PT32002062

SET SCREW M4-.7 X 5 SLOTTED

47

PT32002047

COLLET NUT

63

PT32002063

SAFETY SHIELD

48

PT32002048

GRINDING BIT 1/8" 100 GRIT

64

PT32002064

KNOB BOLT M6-1 X 13, 4-LOBE, D18

101

102

103

104

105

106

Labels & Cosmetics

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

101

PT32002101

MACHINE ID LABEL

104

PT32002104

ELECTRICITY LABEL

102

PT32002102

QR CODE LABEL

105

PT32002105

TOUCH-UP PAINT, GRIZZLY GREEN

103

PT32002103

GRIZZLY.COM LABEL

106

PT32002106

TOUCH-UP PAINT, GRIZZLY BLACK

Safety labels help reduce the risk of serious injury caused by machine hazards. If any label comes

off or becomes unreadable, the owner of this machine MUST replace it in the original location

before resuming operations. For replacements, contact (800) 523-4777 or www.grizzly.com.

Main Parts List (Cont.)

Summary of Contents for T32002

Page 36: ......