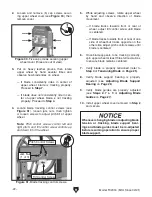

Serious cuts, amputation, or death can occur from contact with the moving saw blade during

operation or if blade breakage occurs. To reduce this risk, anyone operating this machine

MUST completely heed the hazards and warnings below.

CLEANING & SANITIZING. Keep machine and

work area clean and sanitary using solutions

approved for food processing by the USDA. DO

NOT use solvents that can contaminate meat and

cause illness. Properly clean and sanitize saw

before and after each use.

BLADE REPLACEMENT. Under normal condi-

tions, saw blade should be replaced after cutting

approximately 4400 lbs. of meat or bone. To avoid

mishaps that could result in operator injury, make

sure blade teeth face down toward table and

blade is properly tensioned and tracked before

operating.

SUPPORTING CUTS. Cuts should always be

fully supported by table, fence, and included meat

pusher. If necessary to maintain safe cuts, use

auxiliary fixtures. Do not cut very small or thin

pieces that are hard to control.

CUTTING TECHNIQUES. To avoid blade get-

ting pulled off wheels or accidentally breaking

and striking operator, always turn saw

OFF and

wait for blade to come to a complete stop before

backing workpiece out of blade. DO NOT back

workpiece away from blade while saw is running.

DO NOT force or twist blade while cutting. This

could result in blade damage or breakage.

WORKPIECE MATERIAL. This machine is

designed to cut fresh and frozen meat and bones.

This machine is NOT designed to cut wood,

metal, glass, stone, tile, etc.

HAND PLACEMENT. Placing hands or fingers

in line with blade during operation may result in

serious injury if hands slip or workpiece moves

unexpectedly. Do not position fingers or hands in

line with blade, and never reach under table while

blade is moving.

BLADE SPEED. Cutting workpiece before blade is

at full speed could cause blade to grab workpiece

and pull hands into blade. Allow blade to reach full

speed before starting cut. DO NOT start machine

with workpiece contacting blade.

FEED RATE. To avoid risk of workpiece slipping

and causing operator injury, always feed stock

evenly and smoothly.

BLADE CONDITION. Dull blades require more

effort to perform cut, increasing risk of accidents.

Do not operate with dirty, dull, cracked or badly

worn blades. Inspect blades for cracks and miss-

ing teeth before each use. Always maintain proper

blade tension and tracking while operating.

CLEARING JAMS AND CUTOFFS. Always stop

saw and disconnect power BEFORE clearing

scrap pieces that get stuck between blade and

table. Use brush or push stick, not hands, to clean

scraps from table.

BLADE CONTROL. To avoid risk of injury due to

blade contact, always allow blade to stop on its

own. DO NOT try to stop or slow blade with your

hand or the workpiece.

Model T32304 (Mfd. Since 02/21)

-9-

Additional Safety for Meat Saws

Summary of Contents for T32304

Page 52: ......