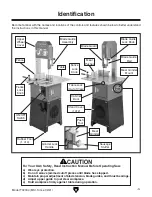

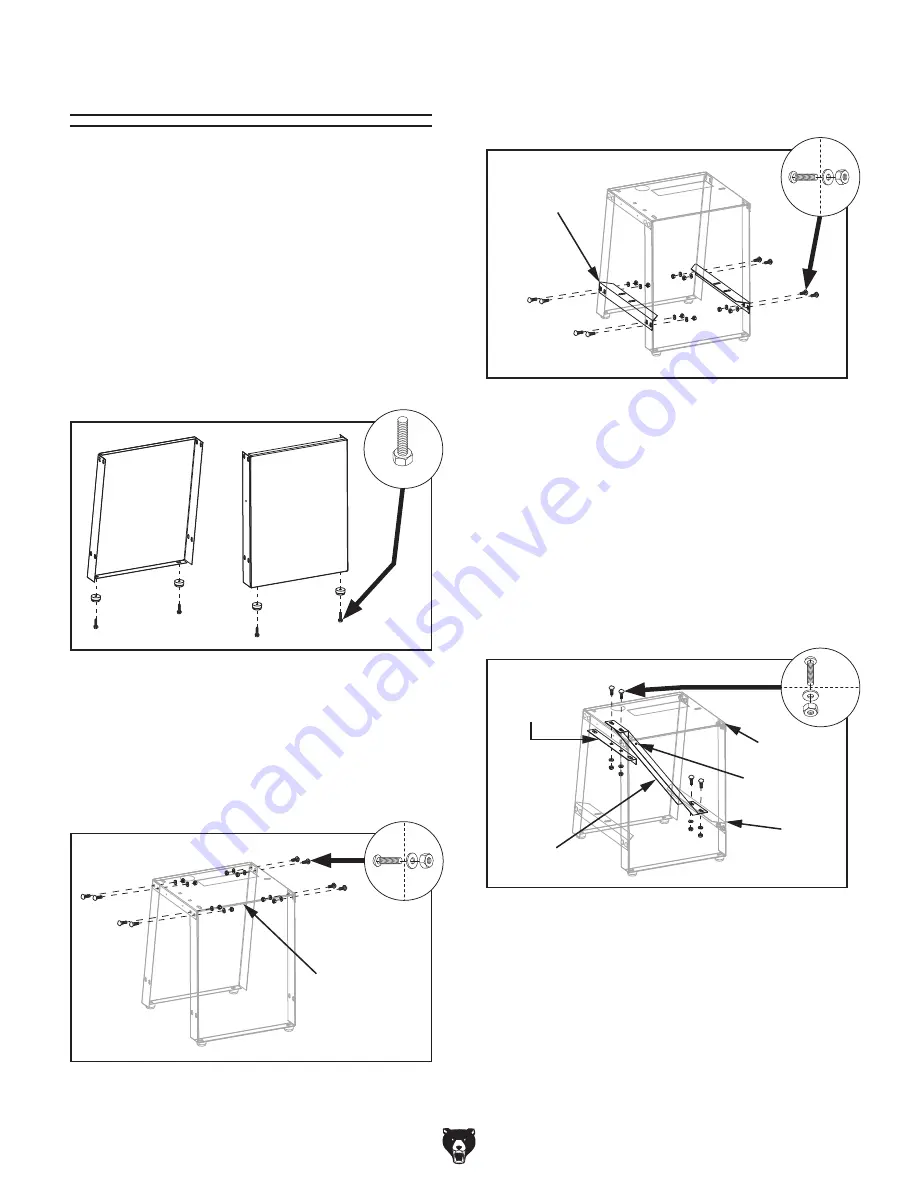

Figure 9. Attaching feet to stand legs.

Stand Top

Figure 10. Attaching stand legs to stand top.

Side Brace

(1 of 2)

Figure 11. Attaching side braces to stand legs.

Upper

Brace

Motor

Mount

Rear

Side

Brace

Clamp

Hole

Stand Top

Figure 12. Attaching motor mount to stand.

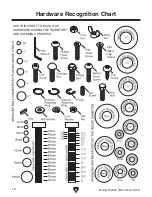

x 4

x 8

x 8

x 4

-16-

Model T32304 (Mfd. Since 02/21)

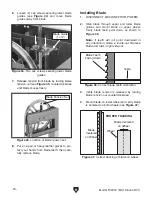

3. Attach side braces to stand legs with (8)

M8-1.25 x 16 carriage bolts, 8mm flat wash-

ers, and M8-1.25 hex nuts (see

Figure 11).

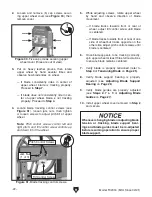

4. Attach motor mount to upper brace through

stand top with (2) M8-1.25 x 16 carriage

bolts, 8mm flat washers, and M8-1.25 hex

nuts (see

Figure 12), then attach motor

mount to rear side brace with (2) M8-1.25

x 16 carriage bolts, 8mm flat washers, and

M8-1.25 hex nuts.

IMPORTANT: Verify clamp hole on motor

mount is positioned on top (see

Figure 12)

before proceeding to the next step.

Assembly

To assemble machine:

1. Insert (4) M6-1 x 20 hex bolts into rubber feet,

and attach feet to each corner on stand legs

(see

Figure 9).

2. Attach stand legs to stand top with (8)

M8-1.25 x 16 carriage bolts, 8mm flat wash-

ers, and M8-1.25 hex nuts (see

Figure 10).

Note: DO NOT completely tighten fasteners

until instructed to in

Step 5.

The machine must be fully assembled before it

can be operated. Before beginning the assembly

process, refer to

Needed for Setup and gather

all listed items. To ensure the assembly process

goes smoothly, first clean any parts that are cov-

ered or coated in heavy-duty rust preventative (if

applicable).

5. Make sure stand top is centered over stand

sides and tighten all loose hex nuts.

Summary of Contents for T32304

Page 52: ......