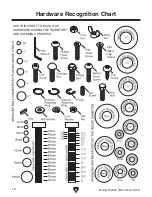

Straightedge

Belt Pulley

Motor

Touching Evenly

Figure 17. Checking pulley alignment with a

straightedge.

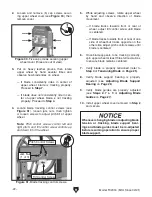

Clamp Hole

Figure 18. Motor mount clamp hole location

(components removed for clarity).

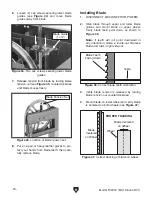

Table

Lock

Table Slot

Open End

Figure 19. Table lock located, and open table

slot aligned with blade.

-18-

Model T32304 (Mfd. Since 02/21)

10. Hold a straightedge close to the center of

both pulleys, and make sure straightedge

fully extends across rims of both pulleys, as

shown in

Figure 17.

— If pulleys are parallel and coplanar,

straightedge will touch the top and bottom

rims on both pulleys. No further adjust-

ment is required.

— If pulleys are parallel but not coplanar,

straightedge will touch the top and bot-

tom rims on one pulley, but will not touch

either rim on the other pulley. In this case,

loosen (4) carriage bolts securing motor

mount, then re-position motor so straight-

edge touches the top and bottom rims on

both pulleys. Repeat

Steps 9–10.

11. Connect motor power cord to power cord

receptacle on rear ON/OFF switch housing,

and secure to motor mount clamp hole (see

Figure 18) with cable holder.

12. Verify table lock location (see Figure 19), and

align open end of table slot with blade.

Summary of Contents for T32304

Page 52: ......