Belt Pulley

¼" Deflection

Motor Pulley

Figure 57. Testing for

1

⁄

4

" V-belt deflection.

Figure 58. Location of motor mount hex nuts.

-40-

Model T32304 (Mfd. Since 02/21)

Tensioning/

Replacing V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belt must be properly

tensioned, and free of cracks, fraying, and wear.

Belt tension and condition should be checked

every month—more often if the bandsaw is used

daily under heavy load.

Items Needed

Qty

Straightedge 36" ................................................. 1

Open-End Wrench 13mm ................................... 1

Hex Wrench 5mm ............................................... 1

Checking & Tensioning V-Belt

1. DISCONNECT MACHINE FROM POWER!

2. Remove table and both stand covers, then

open cabinet door.

Note:

Fence and meat pusher can remain

installed when removing table.

3. Inspect V-belt; if it is cracked, frayed, or

glazed, proceed to

Replacing V-Belt on

Page 41.

4. Check V-belt tension by applying moderate

pressure between pulleys (see

Figure 57).

— If V-belt deflection is approximately

1

⁄

4

",

belt is correctly tensioned and no adjust-

ment is required.

— If deflection is not approximately

1

⁄

4

", V-belt

requires tensioning. Proceed to

Step 5.

5. Loosen (4) hex nuts securing motor to motor

mount (see

Figure 58).

6. Press down on center of motor to tension

V-belt, then tighten (4) hex bolts to secure

motor. Make sure that motor does not twist

while applying pressure.

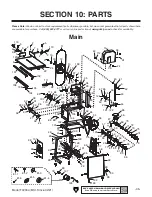

Summary of Contents for T32304

Page 52: ......