Model T32336 (Mfd. Since 05/22)

-19-

Connecting Air Tool

There are various air tools that can be connected

to your air compressor by means of an air hose,

and the setup will vary little across tools, but there

are a couple things to keep in mind before con-

necting a tool or hose.

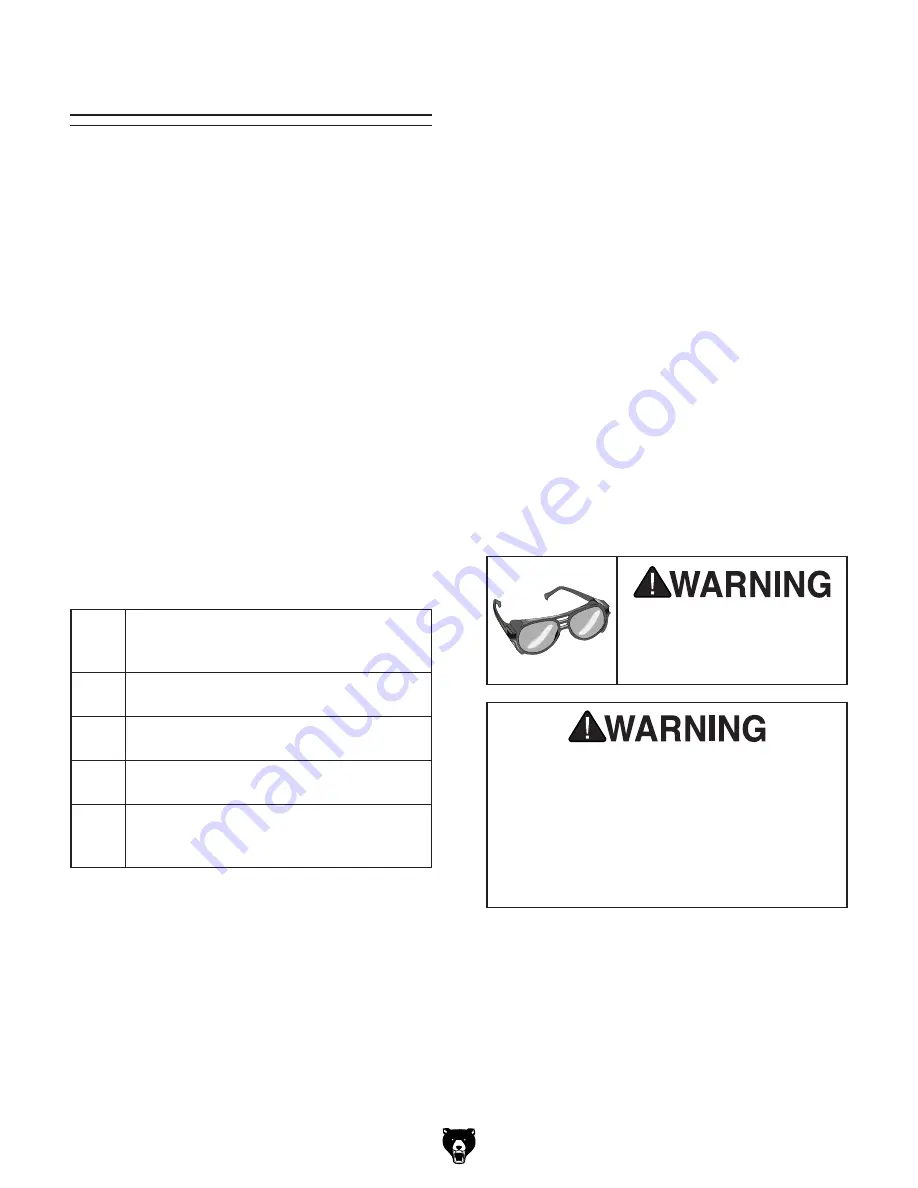

Figure 16. Common duty cycles.

50/50

Compressor can be used for up to half

of its cycle (spends same amount of

time resting as it does working).

60/40 Compressor can be used for up to 60%

of its cycle; spends 40% of time resting.

75/25 Compressor can be used for up to 75%

of its cycle; spends 25% of time resting.

85/15 Compressor can be used for up to 85%

of its cycle; spends 15% of time resting.

100

Compressor does not need to rest.

Engine/motor has a cooling component

allowing for constant air delivery.

Compressing air produces a lot of heat, so the

pump and motor require some resting time in

order to cool down. The "cycle" of an air compres-

sor refers to how long it takes for the compressor

to be used and subsequently cooled. The duty

cycle dictates what percentage of the cycle you

can spend using air before it must rest.

Airflow Delivery (CFM)

The first consideration when choosing an air tool

is whether or not the air delivery is compatible with

your compressor. Smaller compressors, capable

of less than 5 CFM, only supply enough pressure

for smaller air tools like nailers, staplers, chippers,

chisels, grinders, sanders, tire inflators, and paint

sprayers. Air hammers, impact wrenches, impact

hammers, and blow guns will probably require a

larger compressor capable of 10-110 CFM.

Duty Cycle

The duty cycle of your compressor will also have

an effect on how efficient the airflow delivery is.

Refer to

Figure 16 for some common duty cycles

and what they mean.

Your second consideration should be the recom-

mended or required operating pressure of your

tool. An air tool recommended for 70 PSI should

never be connected to a hose or system set to

higher than that operating pressure, as the tool or

valves could burst. A regulator allows tools with a

lower rating than the system to still be attached,

because the line can be adjusted to a safe level.

The Model T32336 has a regulator and pressure

gauge for controlling and observing line pressure.

Operating Pressure (Pounds/Inch

2

)

Connecting Air Tool

Use the following steps as a guide for attaching

an air tool. As there are a wide variety of tool and

hose options, your connections may differ slightly

from this simple outline.

Items Needed

Qty

Air Tool (Rated for 90 PSI or Less) ................... 1

Air Hose ............................................................. 1

Additional Connection Fittings ........... As Needed

Eye injury hazard! Always

wear safety glasses when

handling pressurized air

system.

Always wear personal protective equipment

required by air tool you are using. Pneumatic

grinders, sanders, paint sprayers, etc.,

require a respirator to protect against

long-term respiratory damage. Prolonged

exposure to tools with high sound ratings

can result in hearing loss without the use of

hearing protection.

Summary of Contents for T32336

Page 40: ......