-4-

Model T32336 (Mfd. Since 05/22)

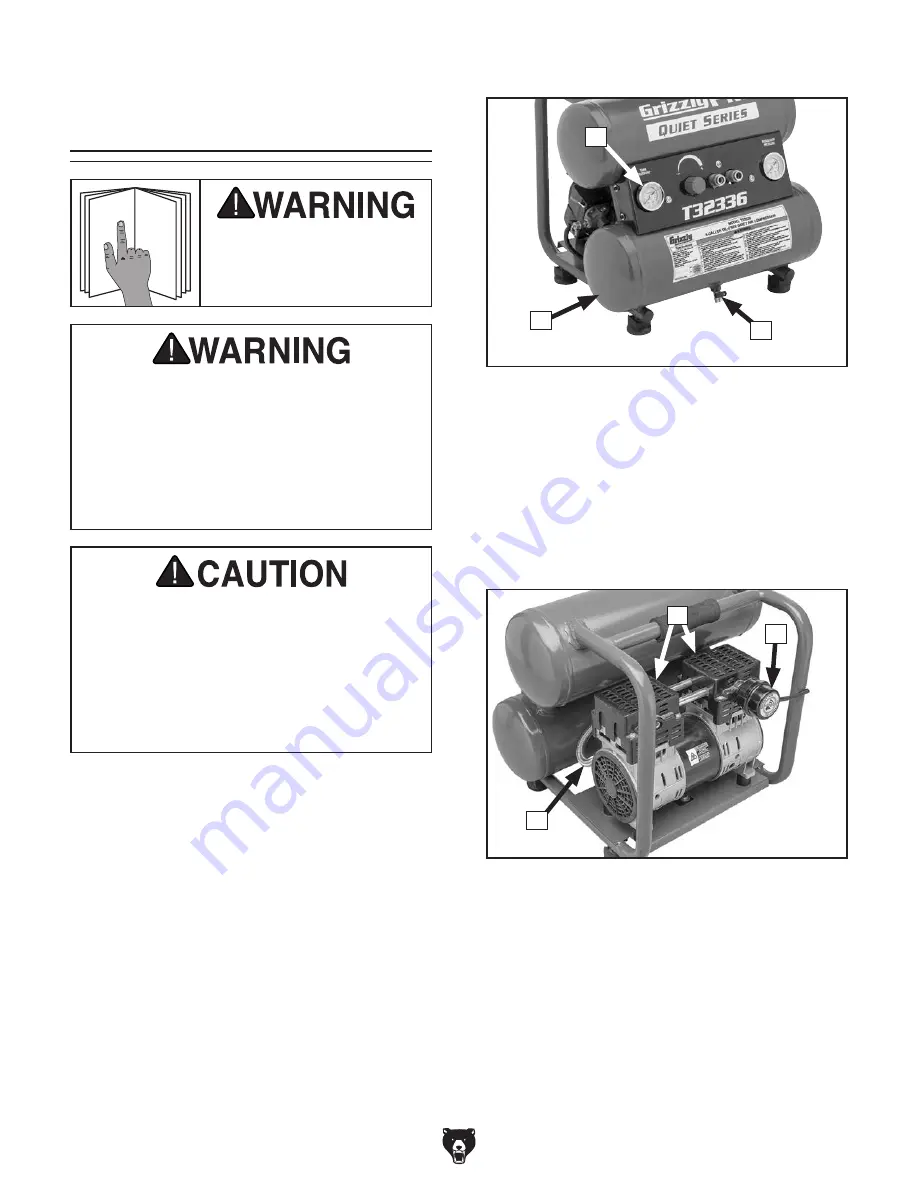

Controls &

Components

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

Refer to the following figures and descriptions to

become familiar with the basic controls and com-

ponents of this machine. Understanding these

items and how they work will help you understand

the rest of the manual and minimize your risk of

injury when operating this machine.

Air Input

C

B

Figure 1. Front air input components.

A

A. Tank Pressure Gauge: Indicates pressure

of air in tanks.

B. Drain Valve: Drains built-up moisture from

tanks when ball valve is opened.

C. Tank (1 of 2): Holds up to 2 gallons of pres-

surized air.

D. Dual Compressor Pump: Uses piston to

draw in and compress air before transferring

air to tanks.

E. Air Filter: Cleans air entering compressor

pump.

F. Exhaust Tube: Transfers compressed air

from pump to tanks.

Figure 2. Rear air input components.

E

F

D

Like all machinery there is potential danger

when operating this machine. Accidents

are frequently caused by lack of familiarity

or failure to pay attention. Use this machine

with respect and caution to decrease the

risk of operator injury. If normal safety pre-

cautions are overlooked or ignored, seri-

ous personal injury may occur.

No list of safety guidelines can be com-

plete. Every shop environment is different.

Always consider safety first, as it applies

to your individual working conditions. Use

this and other machinery with caution and

respect. Failure to do so could result in

serious personal injury, damage to equip-

ment, or poor work results.

Summary of Contents for T32336

Page 40: ......