-14-

Model T32337 (Mfd. Since 05/22)

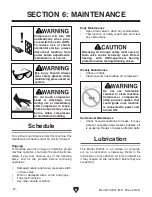

Figure 7. Minimum working clearances.

Electrical Connection

=

20"

17"

Min. 18"

from

Obstructions

Wall

Children and visitors may be

seriously injured if unsuper-

vised around this machine.

Lock entrances to the shop

or disable start switch or

power connection to prevent

unsupervised use.

Site Considerations

Workbench Load

Refer to the

Machine Data Sheet for the weight

and footprint specifications of your machine.

Some workbenches may require additional rein-

forcement to support the weight of the machine

and workpiece materials.

Consider anticipated workpiece sizes and addi-

tional space needed for auxiliary stands, work

tables, or other machinery when establishing a

location for this machine in the shop. Below is

the minimum amount of space needed for the

machine.

Placement Location

Assembly

To assemble machine:

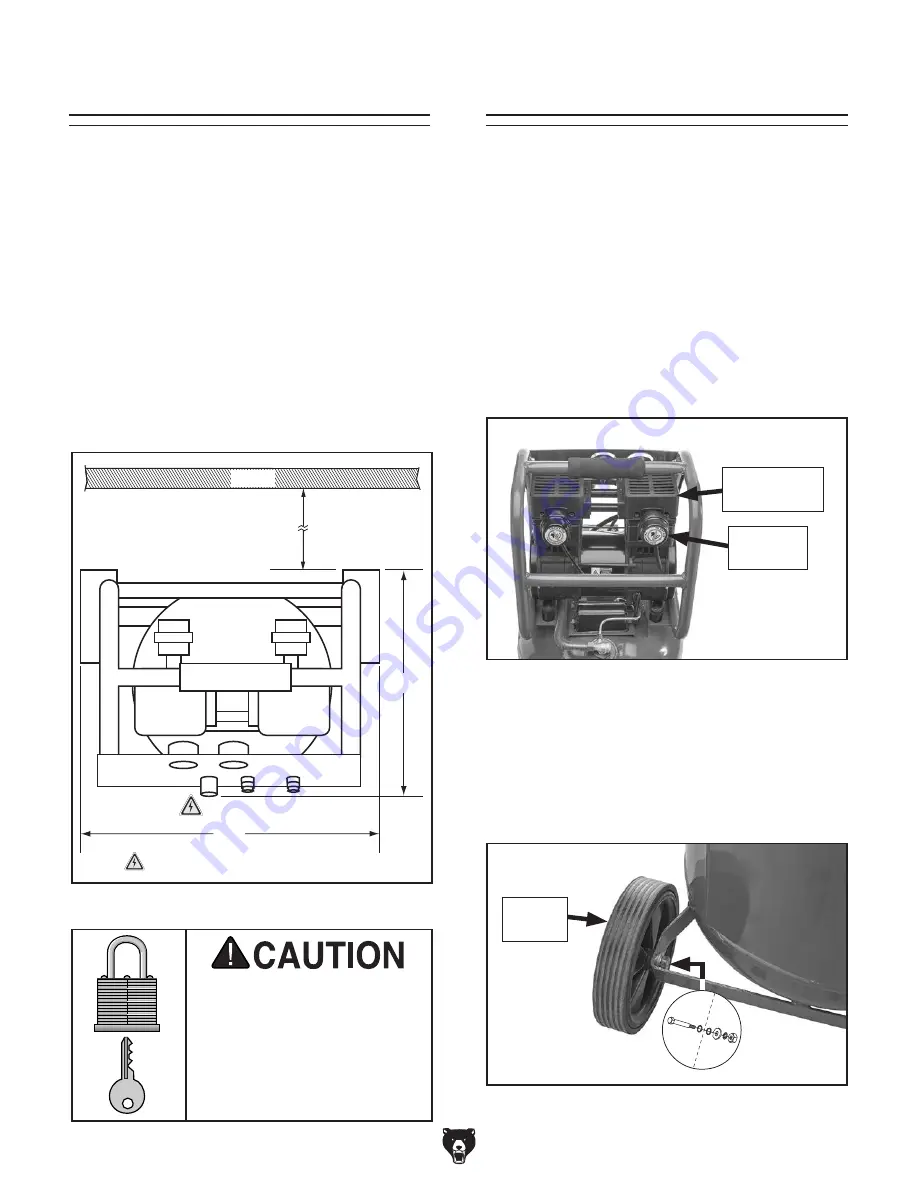

1. Thread air filter assemblies clockwise into

compressor pump heads (see

Figure 8) and

hand tighten.

The machine must be fully assembled before it

can be operated. Before beginning the assembly

process, refer to

Needed for Setup and gather

all listed items. To ensure the assembly process

goes smoothly, first clean any parts that are cov-

ered or coated in heavy-duty rust preventative (if

applicable).

Figure 8. Air filter assemblies installed on

compressor pump.

Air Filter

Assembly

Compressor

Pump Head

2. Attach (2) wheels to air compressor with (2)

3

⁄

8

"-16 x 1

1

⁄

2

" shoulder bolts, (4) 13 x 14 x 2mm

flat washers, (2)

3

⁄

8

" flat washers, (2)

3

⁄

8

" inter-

nal tooth washers, and (2)

3

⁄

8

"-16 hex nuts

(see

Figure 9).

Figure 9. Wheel attached to air compressor.

x 2

Wheel

(1 of 2)

Summary of Contents for T32337

Page 40: ......