Model T32337 (Mfd. Since 05/22)

-31-

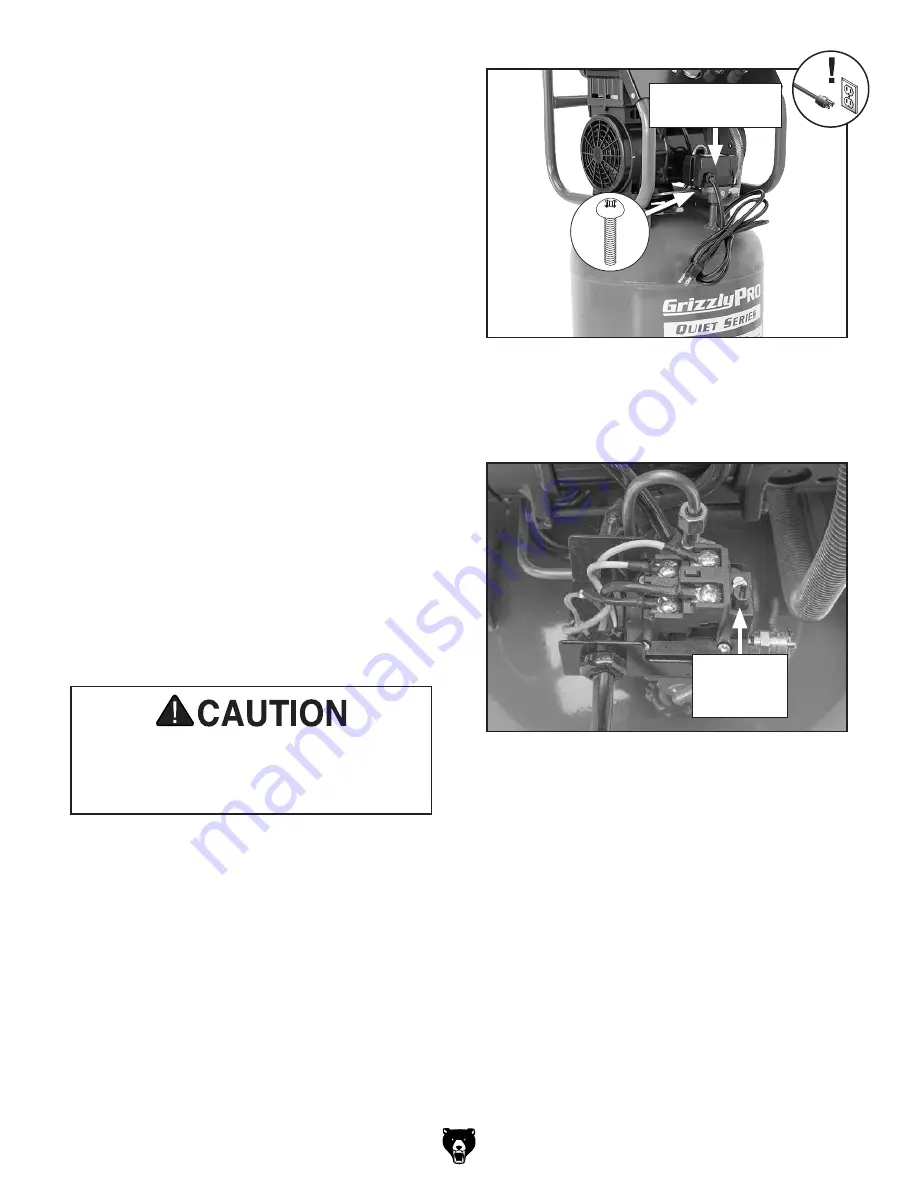

Pressure Switch

Cover

Cut-Out

Adjustment

Screw

— Turn screw half turn clockwise to increase

both settings.

— Turn screw half turn counterclockwise to

decrease both settings.

6. Install pressure switch cover.

7. Connect machine to power, start compres-

sor, and cycle compressor through cut-in/

cut-out pressures. If compressor does not

automatically turn

OFF at 150 PSI, turn

machine

OFF before pressure reaches 155

PSI. Adjust pressure switch settings until cut-

out pressure is 150 PSI or lower.

Adjusting Only Cut-Out Setting

If only the maximum tank pressure setting needs

to be adjusted, then follow these steps. Keep

in mind that the allowable pressure differential

between cut-in pressure and cut-out pressure

must be kept between 30–40 PSI. Exceeding this

range can cause the compressor to overheat.

To adjust only cut-out setting:

1. Operate compressor and record cut-in and

cut-out pressures.

2. DISCONNECT MACHINE FROM POWER!

Releasing air through safety relief valve

can be extremely loud. Protect hearing with

ANSI-approved hearing protection while

performing following step.

3. Use safety relief valve to reduce tank pres-

sure to less than 10 PSI.

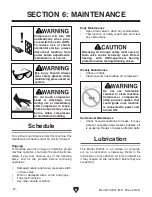

4. Remove Phillips head screw shown in

Figure 32 to remove pressure switch.

5. Adjust screw shown in Figure 33 to change

maximum tank pressure setting.

— Turn screw half turn clockwise to increase

tank pressure.

— Turn screw half turn counterclockwise to

decrease tank pressure.

6. Install pressure switch cover.

7. Connect machine to power, start compres-

sor, and cycle compressor through cut-in/

cut-out pressures. If compressor does not

automatically turn

OFF at 150 PSI, turn

machine

OFF before pressure reaches 155

PSI. Adjust pressure switch settings until cut-

out pressure is 150 PSI or lower.

Figure 33. Location of cut-out only adjustment

screw.

Figure 32. Location of pressure switch cover

Phillips head screw.

Summary of Contents for T32337

Page 40: ......