-26-

Model T32338 (Mfd. Since 12/20)

Changing Oil

To change oil:

1. DISCONNECT MACHINE FROM POWER!

2. Remove oil fill plug (see Figure 35).

3. Place drain pan under oil drain plug, then

remove oil drain plug (see

Figure 35).

Items Needed

Qty

Drain Pan ........................................................... 1

Wrench or Socket 10mm ................................... 1

Wire Brush ......................................................... 1

Teflon Tape ........................................ As Needed

Model T28041 (or SAE 30 Equiv.) ............... 1 Qt.

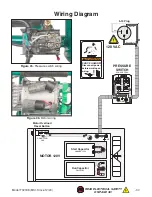

Figure 35. Location of oil fill and oil drain plugs.

4. Clean drain plug threads.

5. When oil is fully drained, wrap drain plug

threads with Teflon tape, then install drain

plug.

6. Add oil to compressor until oil level is between

bottom and top of red circle on oil sight glass

(see

Figure 34 on Page 25), then install fill

plug.

Note:

There is also a dipstick connected to oil

fill plug. Oil level should reach between

L and

H marks on dipstick.

The air filter helps prevent impurities and dust

from entering the compressor and reduces noise.

A dirty filter will result in a less efficient system

and could become a fire hazard.

To check air filter:

1. DISCONNECT MACHINE FROM POWER!

Checking Air Filter

— If filter is fairly clean and there has not

been a drop in efficiency of compressor,

replace cap. No replacement is required.

— If filter is dirty or clogged, or there has

been a drop in efficiency of compressor,

replace cap. Proceed to

Step 4.

4. Replace old filter with new filter element (refer

to Part #11 in

Parts beginning on Page 38).

Figure 36. Air filter assembly components.

Cap

Releasing air through safety relief valve

can be extremely loud. Protect hearing

with ANSI-approved hearing protection in

following step.

2. Use safety relief valve to reduce tank pres-

sure to less than 10 PSI.

3. Remove wing nut shown in Figure 36 to

remove filter cap and access filter.

Oil Fill

Plug

Oil Drain Plug