Model T32338 (Mfd. Since 12/20)

-25-

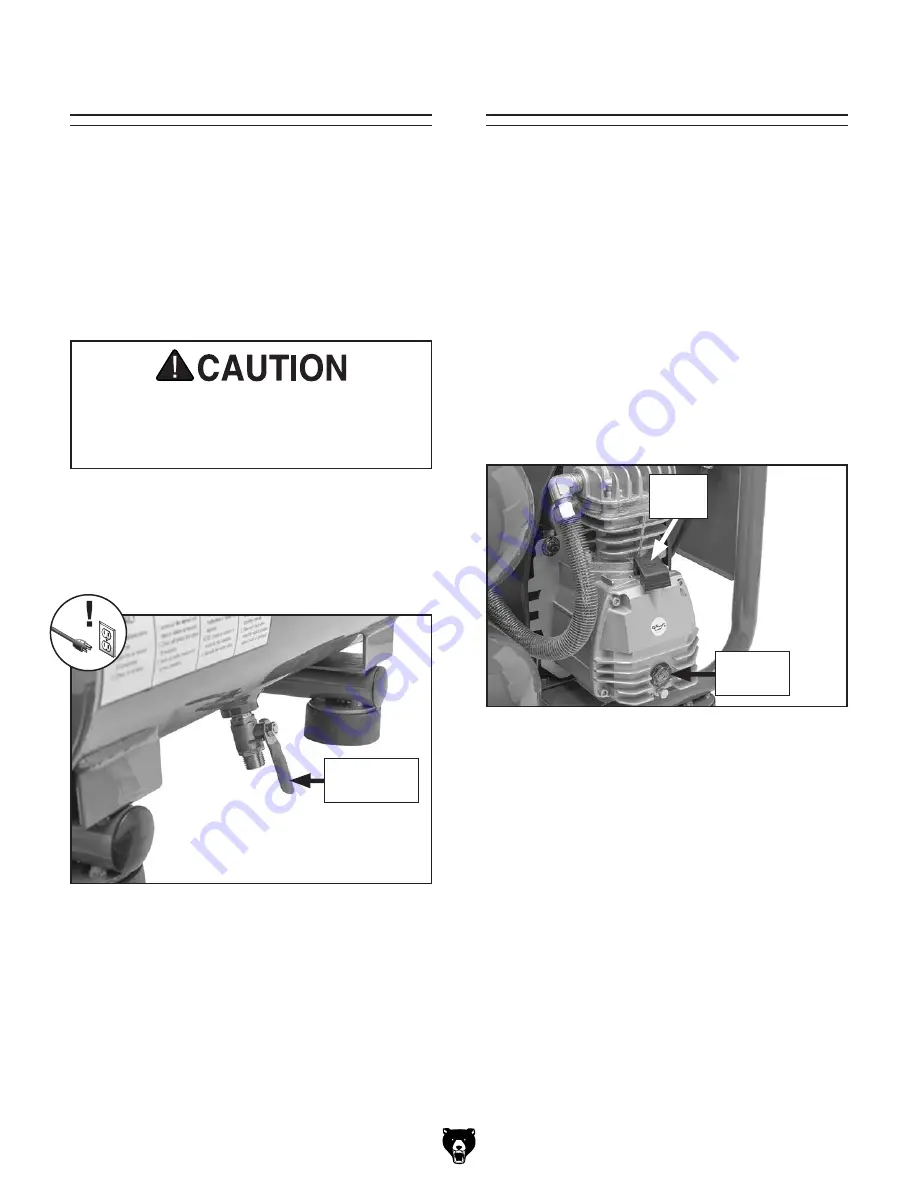

The oil level in the Model T32338 should be

checked daily to prevent overheating and dam-

age to the compressor. Change the oil every 500

hours of use. See Accessories on

Page 23 for an

air compressor oil offered by Grizzly.

Lubrication

To check oil level:

1. Check oil sight glass (see Figure 34). Oil

level should be kept between bottom and top

of red circle.

— If oil level is between top and bottom of red

circle, no additional oil is needed.

— If oil level is below bottom of red circle,

proceed to

Step 2.

2. DISCONNECT MACHINE FROM POWER!

3. Remove oil fill plug (see Figure 34).

4. Add oil to compressor until oil level is between

bottom and top of red circle, then install fill

plug.

Note:

There is also a dipstick connected to oil

fill plug. Oil level should reach between

L and

H marks on dipstick.

Checking Oil Level

Item Needed

Qty

Model T28041 (or SAE 30 Equiv.) ..... As Needed

Some water may accumulate in the tanks depend-

ing on usage and humidity. Drain water from

the tanks daily to increase the lifespan of the

compressor and air tools and to prevent tank

corrosion.

Draining Tanks

Figure 33. Drain valve handle open.

Drain Valve

Handle

To drain tanks:

1. DISCONNECT MACHINE FROM POWER!

2. Use safety relief valve to reduce tank pres-

sure to less than 10 PSI.

3. Open drain valve (see Figure 33) to drain

condensation from tanks.

Releasing air through safety relief valve

can be extremely loud. Protect hearing

with ANSI-approved hearing protection in

following step.

Figure 34. Location of oil sight glass and oil fill

plug.

Oil Sight

Glass

Oil Fill

Plug