-34-

Model T32338 (Mfd. Since 12/20)

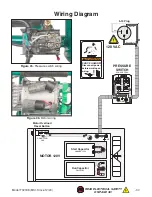

Figure 41. Location of pressure switch cover

Phillips head screw.

Pressure Switch

Cover

Releasing air through safety relief valve

can be extremely loud. Protect hearing with

ANSI-approved hearing protection while

performing following step.

3. Use safety relief valve to reduce tank pres-

sure to less than 10 PSI.

4. Remove Phillips head screw shown in

Figure 41 to remove pressure switch cover.

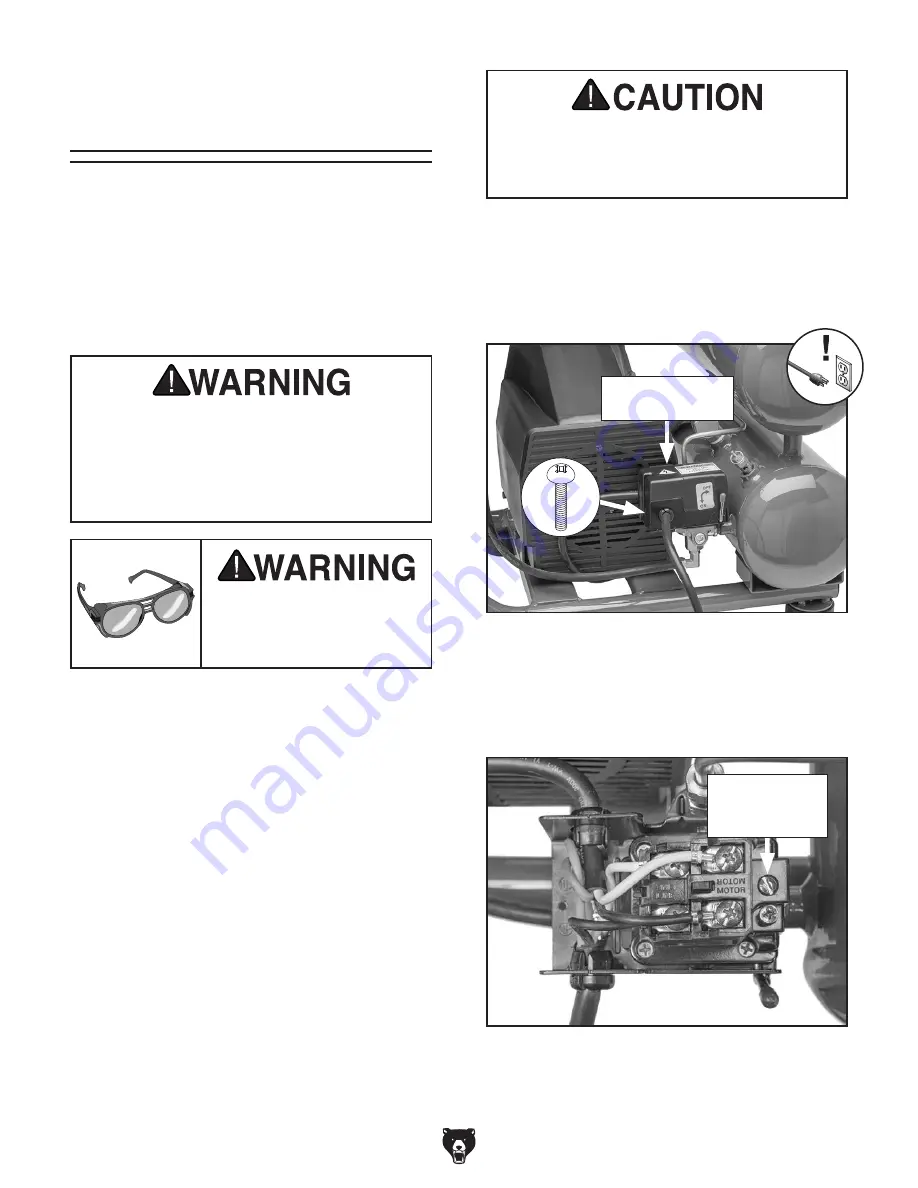

5. Adjust screw shown in Figure 42 to change

minimum and maximum tank pressure

settings.

Figure 42. Location of cut-in/cut-out adjustment

screw.

Cut-In/Cut-Out

Adjustment

Screw

To adjust cut-in/cut-out settings:

1. Operate compressor and record cut-in and

cut-out pressures.

2. DISCONNECT MACHINE FROM POWER!

Adjusting Cut-In/

Cut-Out Settings

The pressure switch ensures the compressor will

turn

ON when the tank pressure drops to approxi-

mately 95 PSI (cut-in pressure), and will turn

OFF

when the tank pressure reaches 125 PSI (cut-out

pressure). Should the pressure switch fail to turn

OFF the machine, the safety relief valve will open

shortly after the pressure exceeds 125 PSI and

prevent over-pressurization.

Cut-in and cut-out settings have been

factory set at proper PSI range. Only adjust

pressure switch settings if compressor

is cutting-in or cutting-out at incorrect

pressures. Tanks could burst if filled with

more pressure than it is designed for.

Eye injury hazard! Always

wear safety glasses when

handling pressurized air

system.

Tools Needed

Qty

Phillips Head Screwdriver #2 ............................ 1

Flat Head Screwdriver

1

⁄

4

" .................................. 1

Adjusting Cut-In/Cut-Out Settings

If the minimum and maximum tank pressure set-

tings both have to be raised or lowered at the

same time, then follow these steps.