OM-TDH/TDHC 7

The kettle should be installed in a ventilated room for efficient performance. Items which

might obstruct or restrict the flow of air for combustion and ventilation must be removed.

The area directly around the appliance must be cleared of any combustible material.

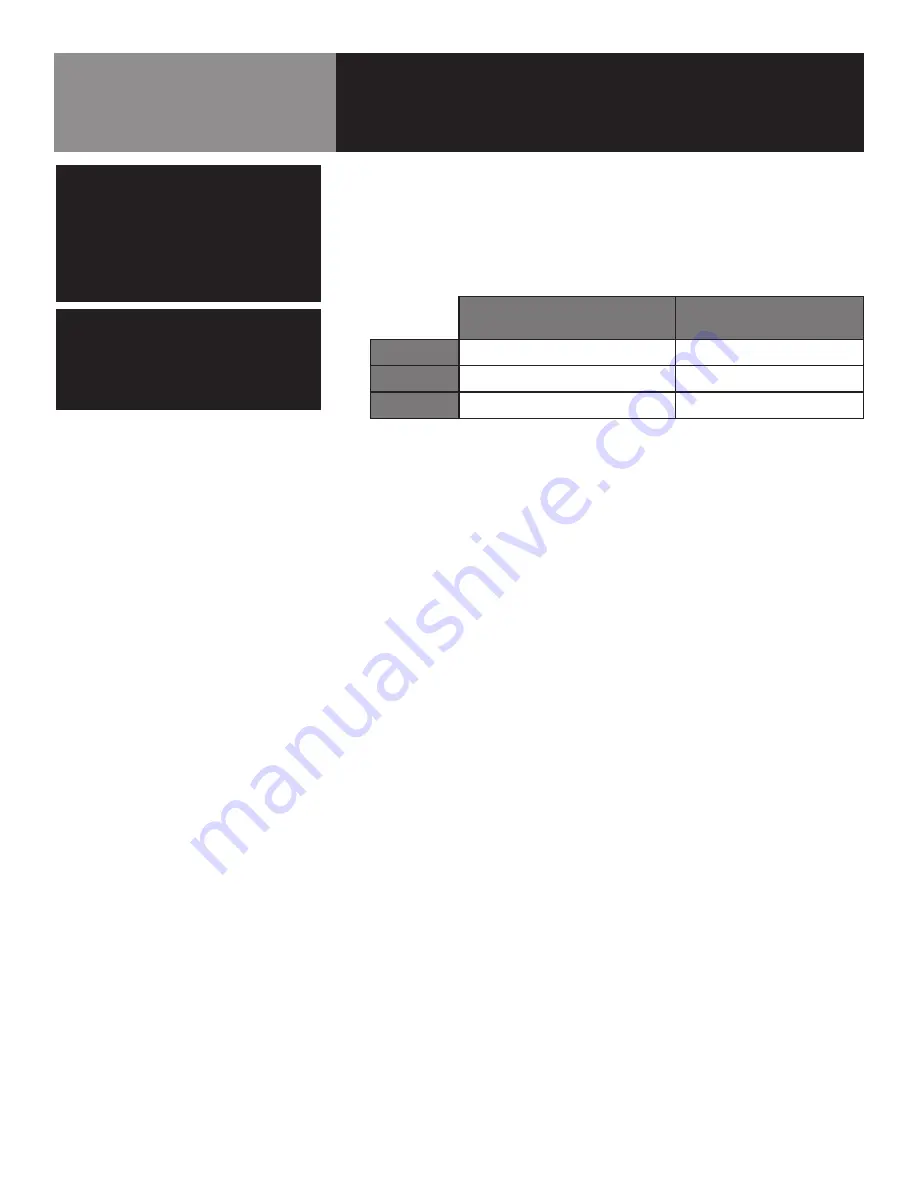

1. Installation on combustible floors is allowed. Minimum clearances between the

unit and combustible surfaces is as follows:

2. We recommends installation of the unit under a vent hood. The base must be

fastened to a working surface or stand.

3. Complete the piping to the gas service main using ½ inch IPS pipe or an

approved equivalent.

4. Provide 115 VAC, 60 cycle, 1 phase, 1 AMP electric service. Local codes and/

or The National Electrical Code should be observed in accordance with ANSI/

NFPA-70 latest edition. AN ELECTRICAL GROUND IS REQUIRED. The electrical

schematic is located on the inside of the service panel and in this manual.

5. Electrical connection to the unit must be water resistant sealtite conduit type or

equal and utilize the water resistant conduit fitting provided on the unit.

6. The installation must conform with local codes or the American National

Standards Z223.1 - latest edition National Fuel Gas Code. The kettle should be

installed in an adequately ventilated room with provision for adequate air supply.

The best ventilation will employ a vent hood and exhaust fan with no direct

connection between the vent duct and the kettle flue. DO NOT obstruct the flue

or vent duct after installation.

7. PRESSURE TEST WARNING

a) Test pressure exceeding ½ PSIG (3.45 kPa). During pressure testing of the

gas supply piping system at pressures exceeding ½ PSIG, the appliance

and its individual shutoff valve must be disconnected from the gas supply

piping system.

b) Test pressure equal to or less than ½ PSIG (3.45 kPa). During pressure

testing of the gas supply piping system at pressures equal to or less than

½ PSIG, the kettle must be isolated from the gas supply piping system by

closing its individual manual shutoff valve.

Installation

WARNING

THE KETTLE MUST BE INSTALLED BY

PERSONNEL QUALIFIED TO WORK WITH

GAS, ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT.

WARNING

THIS UNIT IS FOR COMMERCIAL USE. DO NOT

USE HOME OR RESIDENTIAL GRADE GAS

CONNECTIONS. THEY DO NOT MEET GAS

CODES AND COULD BE HAZARDOUS.

Model

Minimum Clearance from

Combustible walls

Recommended

Clearances

Left Side

1 in.

1 in.

Right Side

0 in.

12-16 in. for servicing

Rear

1 in.

3 in. for faucet bracket

Summary of Contents for TDB 48A

Page 31: ...OM TDH TDHC 31 Wiring Diagram For Classic Control Models ...

Page 32: ...32 OM TDH TDHC Wiring Diagram For Advanced Control Models ...

Page 34: ...34 OM TDH TDHC ...

Page 35: ...OM TDH TDHC 35 ...

Page 36: ...36 OM TDH TDHC ...