Principle of operation

10

Dat

e

of i

ss

u

e : J

a

nu

a

ry 2011

Automatic Greasing System

Twin-3

EG1703P03

2.3

Twin pump unit

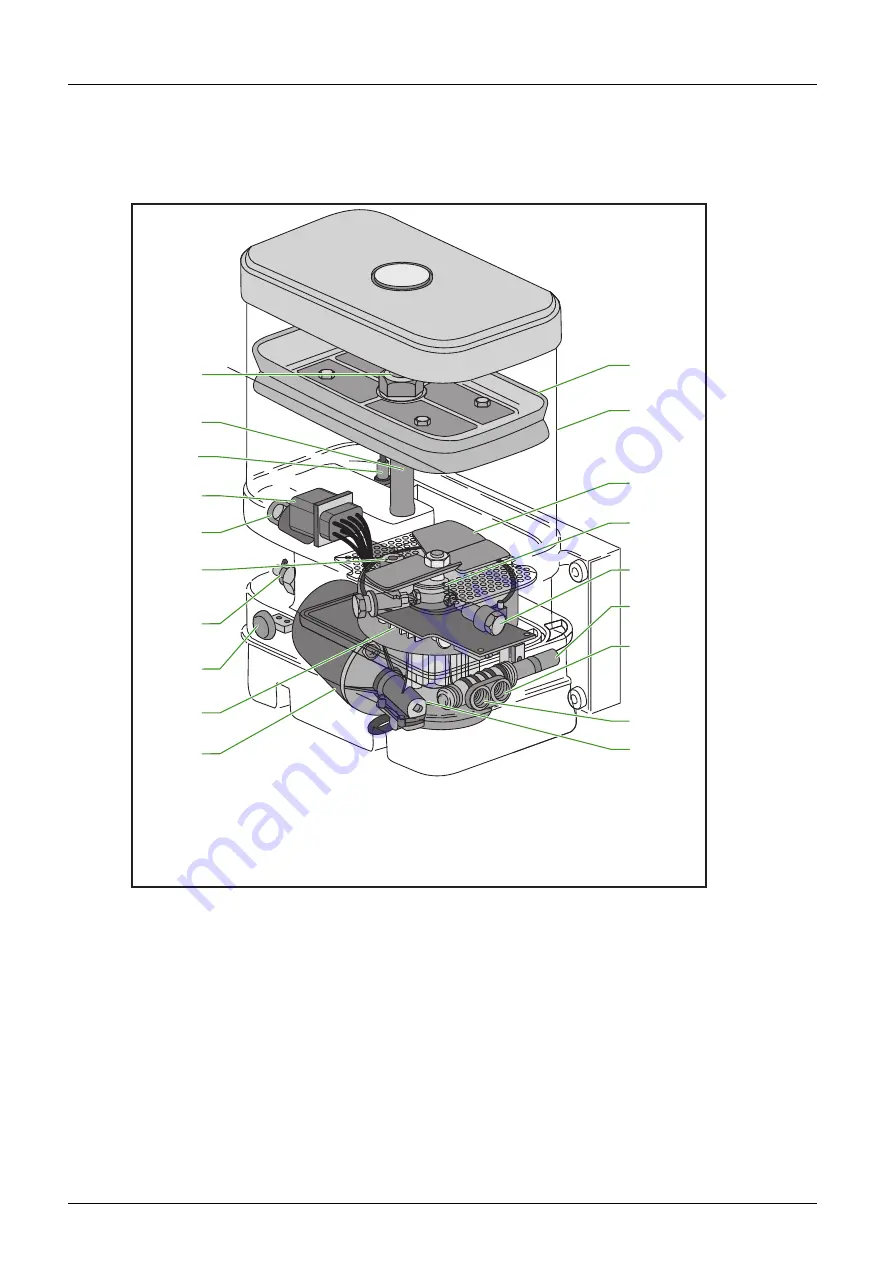

The Twin pump unit consists of various parts. These parts are shown in Figure 2.2.

Figure 2.2

Twin pump unit

The heart of the pump is an electrical-driven piston-pump. This pump consists of three radially-

placed fixed cylinders and pistons (5). The electromotor drives the axle through the mechanical

transmission (9). A cam (4) is fixed on the axle that moves the three pistons to and fro, so the grease

is pumped to the distribution blocks through the primary grease lines. In addition to the cam, the

axle drives the stirring gear (3) located at the bottom of the reservoir and pushes the grease

downwards. A compression channel is located between the pump and the grease channels to the

primary lines. A relief valve (14) and a 5/2-way valve (6) are located in the compression channel.

The relief valve is a protection that leads the grease back to the reservoir when the grease pressure

exceeds 250 bar. The 5/2-way valve determines the primary grease line-A or -B through which

greasing takes place. It has an important task in fulfilling the four phases of the greasing cycle (see

paragraph 2.2).

1

2

3

4

5

6

7

8

9

1

2

11

1

0

1

3

1

4

1

5

16

1

7

18

1

9

1. Follower plate

2. Grease reservoir

3. Stirring gear

4. Cam

5. Cylinder and pistons (3x)

6. 5/2-way valve

7. Primary grease line-A outlet

8. Primary grease line-B outlet

9. Mechanical transmission

10. Electro-motor

11. Control unit

12. Test push-button

13. Filler coupling with grease filter

14. Relief valve

15. Bleeding and grease overflow out-

let

16. Electric connector

17. Minimum level switch

18. Guide rod follower plate

19. Bleeding and grease overflow

channel, connected to the

bleeding and grease overflow

outlet (no. 15)