Page 18

Blade Wheel Options

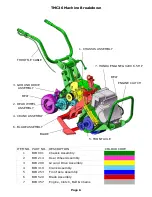

Reversible Blade Wheels

The standard blade-wheels (E) fitted to the

TMC26 can be used with all sod-blade

widths from 40cm (16”) and wider.

The blade-wheels can be reversed or

turned inside out to space them further

apart to give the machine a wider stance

for better stability. When the wheels are

reversed, only sod-blade widths of 45cm

(18”) plus can be fitted

Narrow Blade Wheels

Narrow blade-wheels are available to ac-

commodate sod-blade widths down to

30cm (12”)

Removing the Blade Wheels

Ensure that the machine is properly sup-

ported to take the weight off the wheels for

removal (see Hoisting the Machine)

Place the Ground Drive Lever (C) in the for-

ward engaged position and using the Tee

Wrench (D) provided, undo the three wheel

nuts. When refitting ensure that the wheel

is properly located and tighten the three

nuts firmly.

Hoisting the Machine

Eyelet (A) is provided on the TMC26 to ena-

ble the machine to be lifted for loading or

to enable the blade wheels to be removed.

Before using the eyelet, tighten the depth

clamp lever (B) firmly. Ensure that the

lifting means is securely attached to the

lifting eyelet and that it is capable of sup-

porting the weight of the machine. (see

machine specifications)

A

D

B

C

A

B

E