5.1 Safety instructions

4

Unpacking and inspection

Installation 5

The inverter is thoroughly tested and inspected strictly before delivery. Our inverters

leave our factory in proper electrical and mechanical condition. Special packaging

ensures safe and careful transportation. However, transport damage may still occur. The

shipping company is responsible in such cases. Thoroughly inspect the inverter upon

delivery. Immediately notify the responsible shipping company if you discover any

damage to the packaging which indicates that the inverter may have been damaged or if

you discover any visible damage to the inverter. We will be glad to assist you, if required.

When transporting the inverter, the original or equivalent packaging should be used, and

the maximum layers for original carton is four, as this ensures safe transport.

After opening the package, please check the contents of the box. It should contain the

following, Please check all of the accessories carefully in the carton. If anything missing,

contact your dealer at once.

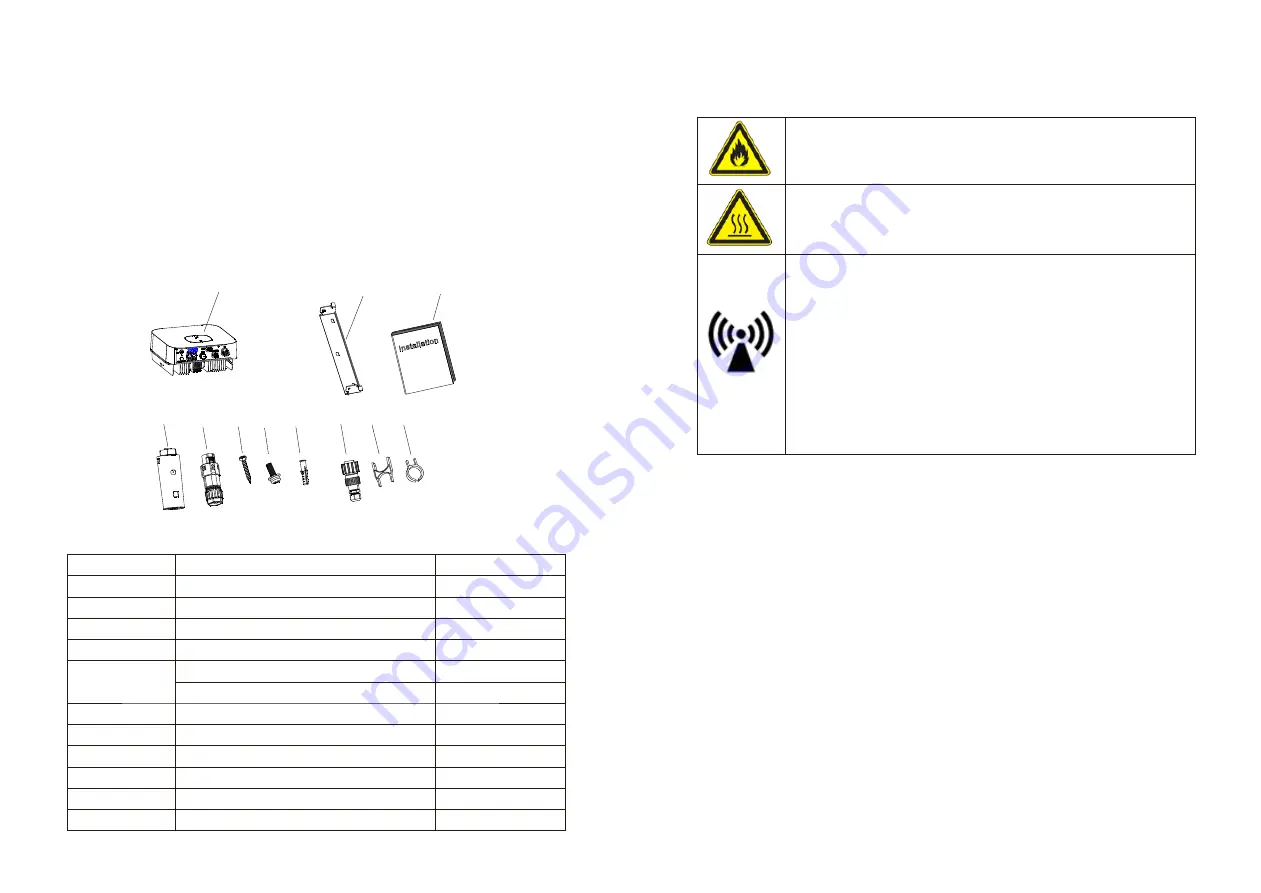

Danger to life due to fire or explosion

Ø

Despite careful construction, electrical devices can cause fires.

Ø

Do not install the inverter on easily flammable materials and where

flammable materials are stored.

Risk of burns due to hot enclosure parts

Mount the inverter in such a way that it cannot be touched

inadvertently.

Possible damage to health as a result of the effects of radiation!

Ø

In special cases, there may still be interference for the specified

application area despite maintaining standardized emission limit

values (e.g. when sensitive equipment is located at the setup

location or when the setup location is near radio or television

receivers).In this case, the operator is obliged to take proper action

to rectify the situation.

Ø

Never install the inverter near the sensitive equipment

(

e.g.

Radios, telephone, television, etc

)

.

Ø

Do not stay closer than 20 cm to the inverter for any length of time

unless it is absolutely necessary.

Ø

Growatt assumes no responsibility for compliance to EMC

regulations for the complete system.

Ø

All electrical installations shall be done in accordance with the local and national

electrical codes. Do not remove the casing. Inverter contains no user serviceable

parts. Refer servicing to qualified service personnel. all wiring and electrical

installation should be conducted by a qualified service personnel .

Ø

Carefully remove the unit from its packaging and inspect for external damage. If you

find any imperfections, please contact your local dealer.

Ø

Be sure that the inverters connect to the ground in order to protect property and

personal safety.

Ø

Both AC and DC voltage sources are terminated inside the Inverter. Please

disconnect these circuits before servicing.

Ø

This unit is designed to feed power to the public power grid (utility) only. Do not

connect this unit to an AC source or generator. Connecting Inverter to external

devices could result in serious damage to your equipment.

Ø

This unit is designed to feed power to the public power grid (utility) only. Do not

connect this unit to an AC source or generator. Connecting Inverter to external

devices could result in serious damage to your equipment.

Ø

When a photovoltaic panel is exposed to light, it generates a DC voltage. When

connected to this equipment, a photovoltaic panel will charge the DC link

capacitors.

Ø

Energy stored in this equipment's DC link capacitors presents a risk of electric shock.

Even after the unit is disconnected from the grid and photovoltaic panels, high

voltages may still exist inside the Inverter. Do not remove the casing until at least 5

minutes after disconnecting all power sources.

Ø

Although designed to meet all safety requirements, some parts and surfaces of

Inverter are still hot during operation. To reduce the risk of injury, do not touch the

heat sink at the back of the Inverter or nearby surfaces while Inverter is operating.

12

11

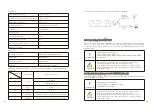

A

C

D

E

F

G

H

I

J

B

K

Object

Description

Quantity

A

AC coupled Inverter

1

B

Mounting bracket

1

C

Quick Guide

1

D

Monitor(Optional)

1

E

COM PORT Signal connector

1

SYS COM PORT Signal connector

1

F

Self-tapping screws

3

G

Safety-lock screw

1

H

Plastic expansion pipe

3

I

AC connector

1

J

Uninstall signal or AC connector tool

1

K

Uninstall Battery terminal tool

1