12

OPERATION

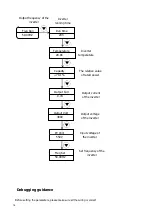

Display Panel

Solar pump inverter uses LCD operation panel. The operation panel is shown in the figure, including 3 LED lights,

LCD display and 5 keys.

Indicator and Key

Name

Function Introduction

POWER

System running

indicator

Green

LED on, inverter is running

ALARM

Warning indicator Yellow

LED on, warning, or LED flashing in auto

operation mode

FAULT

Failure indicator

Red

LED on, system failure

Operation /

Stop Key

1.Press for a short time, then the inverter starts

control;

2. Press for 2s, then inverter stops control.

Confirm /

Programming Key

1.Press for a short time to enter programming mode.

After altering parameter, “press for a short time” to

confirm the alteration

2. Press for 2s to enter the programming menu.

Increment Key

1.When control parameter displays state, increase

parameter number or parameter value;

2. When operation displays data state, according to

operation mode, increase output frequency or display

current operation data.

Decrement Key

1.When control parameter displays state, press for a

short time to decrease parameter number or

parameter value.

2. When operation shows data state, according to

operation mode, decrease output frequency or

display current operation data.

Return Key

Return the initial display.