GROWSPAN

™

ROUND COLD FRAMES

16

Revision date: 01.01.16

OPTIONAL MAIN COVER INSTALLATION W/ ROLL-UP

SIDES (CONTINUED)

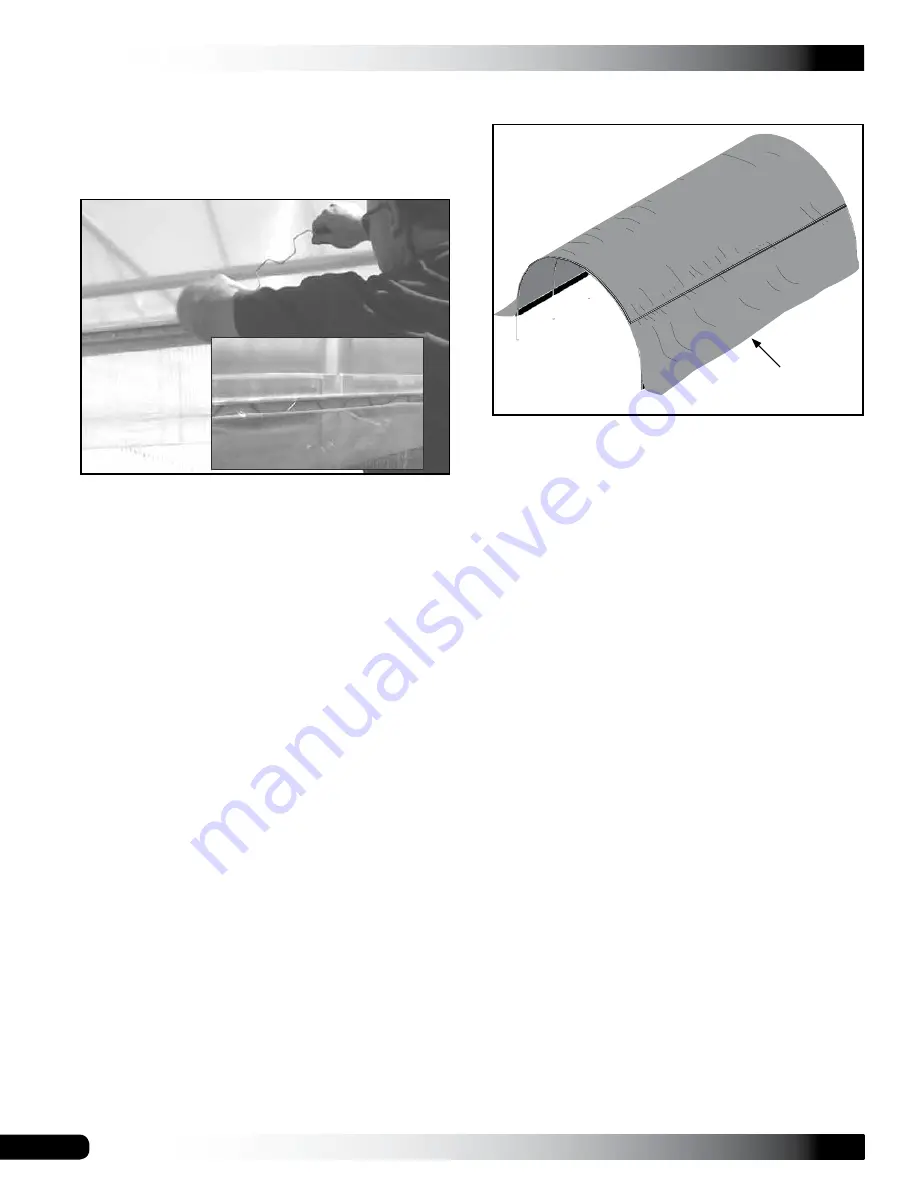

Photos show installing the spring into the U-channel on

the outside of a frame. The process is the same for the

U-channel attached to the top of the end rafters.

5. Continue adding the spring into the U-channel at the

top of the first end rafter. Ensure that an even amount

of the cover is exposed and maintained along the edge

of the frame as it is attached.

NOTE:

The cover material is cut longer/wider than is

required to cover the frame. For easier anchoring, allow

approximately 10" to extend past the edge of the end

rafter as the cover is anchored in place.

6. Continue down both edges of the first end rafter

until the entire length of the end of the main cover is

secured in place.

7. Stretch the cover to the other end of the building and

repeat the steps to secure the main cover in the U-

channel.

NOTE:

Pull the cover tight as the spring is inserted into

the U-channel.

8. After the cover is stretched end-to-end and secured

using the spring and U-channel, move to one side of

the frame and repeat the steps to anchor the main

cover to the first side.

Begin at one end of the U-channel and work toward the

other. It is also possible to begin at the middle of each

side and work toward each end.

NOTE:

Maintain an even length along the side. The

final stretching of the cover takes place when the last

side is secured.

9. After securing the first side, move to the remaining side

and secure it in place.

IMPORTANT:

DO NOT REMOVE TOO MUCH OF THE

EXCESS COVER MATERIAL AT EACH END.

Some

excess main cover material–the material that extends

beyond the end rafters–should remain in place. If the

main cover needs stretched in the future, remove the

spring from the U-channel, grasp the excess material,

pull the cover tight, and reinstall the spring.

The excess material along the sides is rolled up in the

roll-up side assembly.

10. Once the main cover is installed and secured in the

U-channel, follow the instructions provided with the

Twist-of-the-Wrist Assembly if used.

11. Once you have completed the Twist-of-the-Wrist

installation and install your Anti-Billow ropes, read the

Care and Maintenance

section that follows.

Roll-up Portion

of the Cover