GROWSPAN

™

ROUND COLD FRAMES

8

Revision date: 01.01.16

ASSEMBLING THE COLD FRAME COMPONENTS

NOTE

: Assistance is required to assemble the frame.

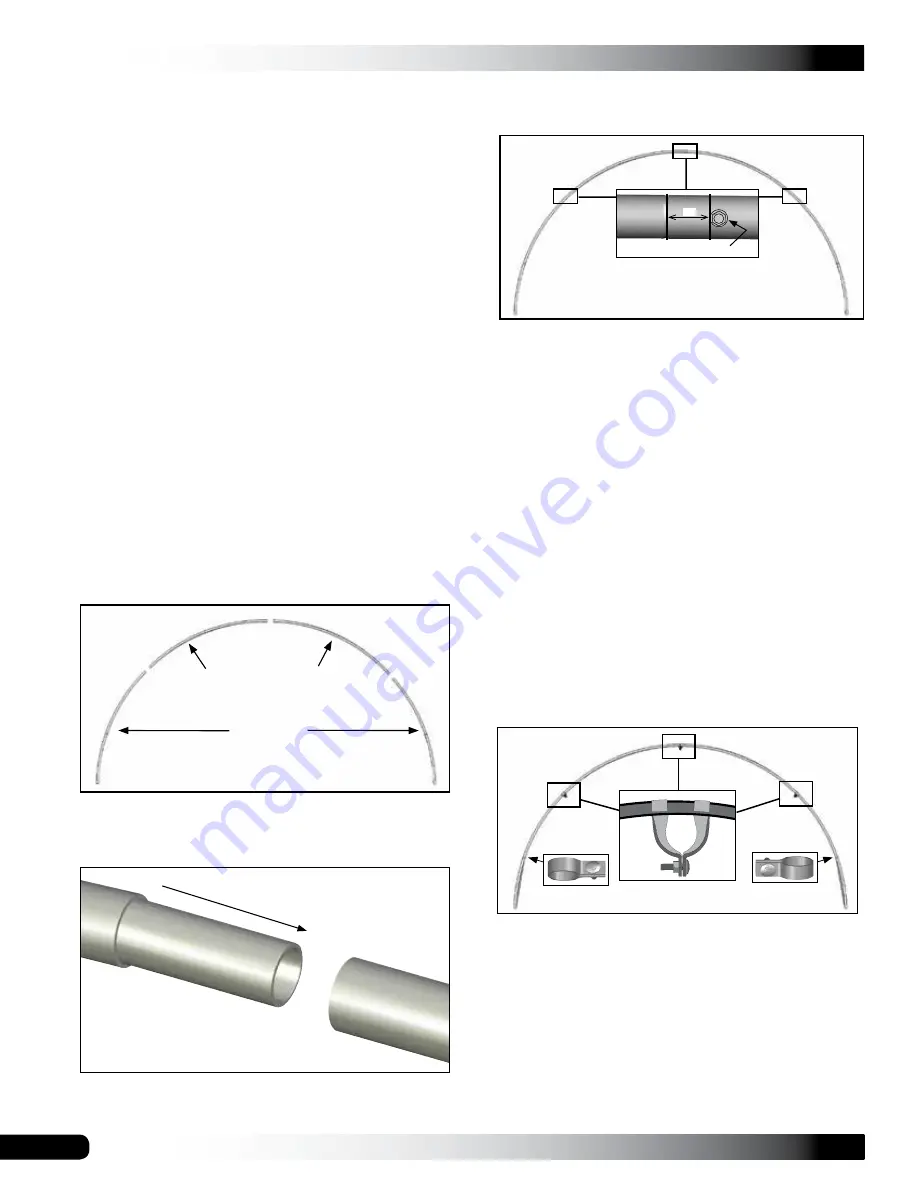

RAFTER ASSEMBLY

Gather the parts:

• Round rafter pipe swaged (#20R1601D)

• Round rafter pipe swaged (#20R1601)

• Round rafter pipe plain (#20R1602)

• End clamp (#102856)

• Band clamp (#QH1402)

• Tek screws

• Nut setter (3/8" x 2-9/16" magnetic)

Rafter Assembly Procedure

Each rafter assembly consists of four (4) rafter pipes: two

(2) swaged pipe sections (#20R1601D) (drilled for ground

posts), one (1) swaged pipe section (#20R1601) (not

drilled) and one (1) plain pipe section (#20R1602).

1. Select the four (4) pipes needed to assemble a rafter

and arrange these on a flat surface as shown below for

assembly.

2. Slide the swaged portion of each rafter pipe into the

plain end of the pipe as shown.

3. With the main rafter pipes seated at each joint and

the rafter positioned on a flat surface, secure only the

center joint with a self-tapping Tek screw.

ATTENTION:

Do not secure the drilled pipes until

the rafter is attached to the ground posts. This allows

holes in the drilled pipes to be aligned with those in the

ground posts.

Install the screws so they will not touch the cover

once it is installed (if equipped). This is typically on

the backside of the rafter, which will be the surface

visible from the

inside

of the shelter once the frame is

assembled.

4. Assemble all the rafters as described and continue with

the steps to complete two (2) end rafters.

END RAFTER ASSEMBLY

Complete the following steps

for the two (2) end rafters

only

.

1. Take one of the assembled rafters and place it on a flat

surface.

2. Slide three (3) end clamps and two (2) band clamps

onto the rafter in the locations noted below.

NOTE:

Do not secure the clamps to the rafter at this

time. These clamps will be repositioned during frame

assembly when the purlin is added.

Use a piece of duct tape (if desired) to keep the clamps

from sliding when the rafter is lifted into position. View

of the end rafter and clamp as shown from the

outside

when the frame is assembled.

3. Repeat the same procedure for the final end rafter.

4. Continue with the

Frame Assembly

instructions.

(#20R1601D)

(#20R1601)

(#20R1602)

1˝

Tek screw