GROWSPAN

™

GOTHIC COLD FRAMES

10

Revision date: 01.01.16

Rafter shown differs in design.

Rafter shown differs in design.

1st Interior Rafter

End Rafter

Rafter shown differs in design.

FRAME ASSEMBLY (continued)

4. From the location marked in the previous step,

measure forty-eight inches (48") and make another

mark on the assembled purlin.

5. Continue to mark the purlin in 48" intervals until all

locations are marked. These marks help to maintain

the 48" on-center rafter spacing of the shelter during

assembly.

6. Repeat this procedure until all assembled purlins are

marked.

7. After assembling all rafters and pre-marking the purlins,

assemble the frame.

ASSEMBLE THE FRAME

After all ground posts are driven in place, rafters are

assembled and purlins pre-marked, assemble the frame.

Gather the parts:

• All rafter assemblies and pre-marked purlins

• Band clamps (#QH1404)

• Cross connector (#102547)

• 5/16" x 2-1/2" machine bolts and 5/16" nuts

• Lifts, ladders, and assistants

• Rope or cable

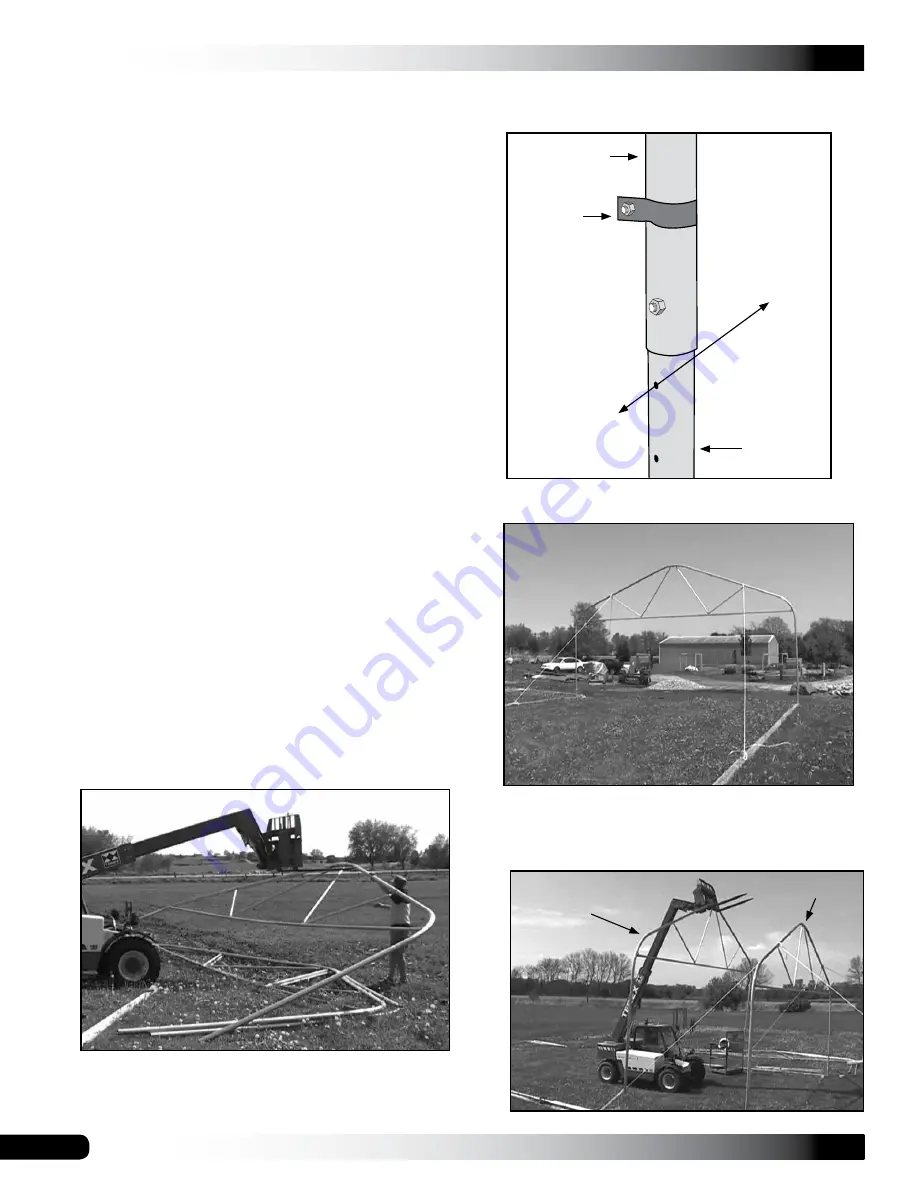

1. Carefully stand the first rafter, slide a band clamp onto

each rafter leg, and place the leg pipes in the first set of

ground posts.

Brace the rafter in place to keep it straight. Depending

on the frame size, a lift and additional assistants may

be needed. Consult Quick Start section for details.

2. Secure the leg pipes to the ground posts using the

5/16" x 2 1/2" machine bolts and nuts.

Inside of

Shelter

Outside of

Shelter

Rafter

Ground

Post

Band

Clamp

ATTENTION:

Stand the rafter so the nuts and bolts of

the end clamps are to the inside of the frame.

3. Use rope or cable to keep the rafter in position.

4. Carefully position the first interior rafter in place and

secure the leg pipes to the ground posts.