7

Revision date: 08.27.19 113466_67_68HBC

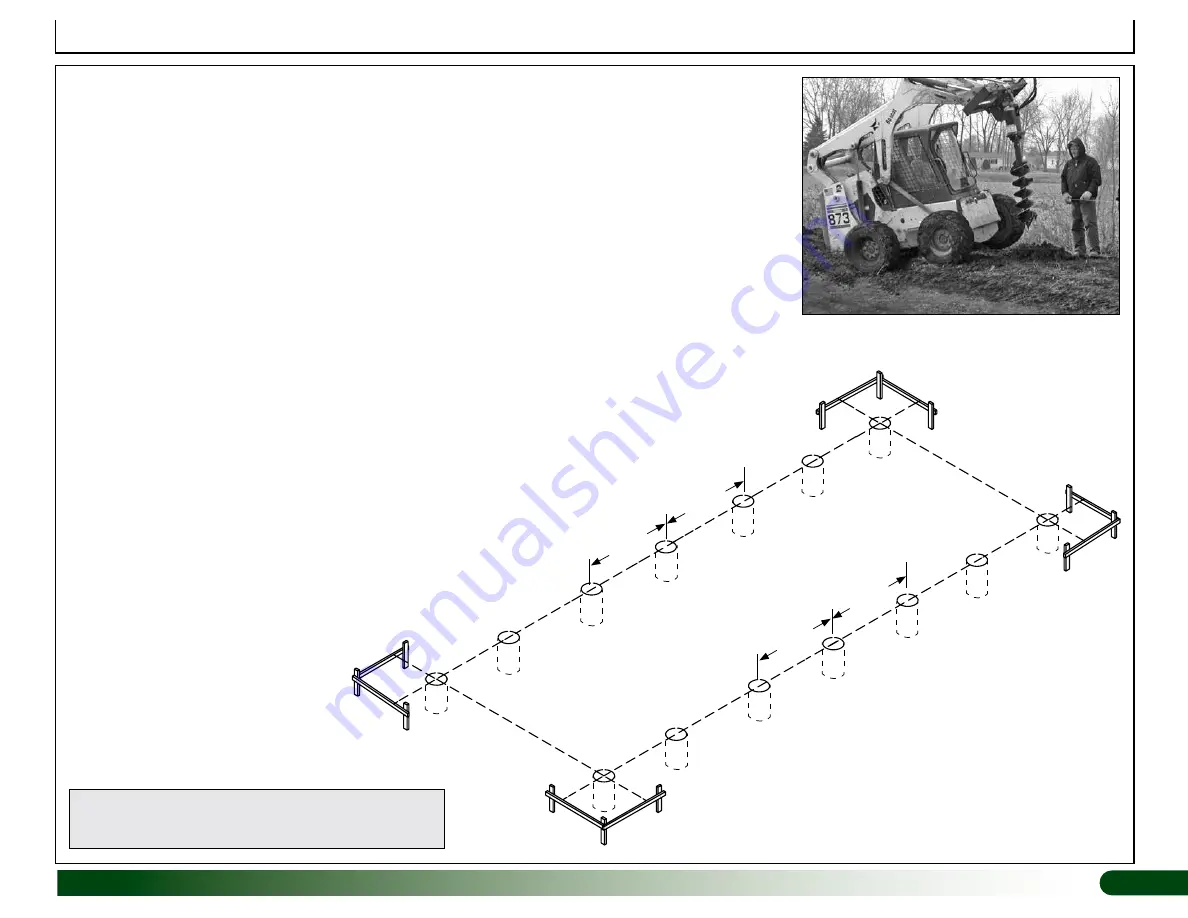

on-center

on-center

on-center

on-center

Set Ground Posts

Drawing may show layout of a different length. Refer to

Quick Start section located at back of these instructions for

on-center measurements and post layout for your frame.

MARK SITE AND DIG POST HOLES FOR CONCRETE

These steps describe marking all ground post locations and digging holes. For some sites, it may not be

possible to complete the procedure in this manner. An alternative procedure such as working from one end

of the building toward the other may be necessary. Determine the best procedure based on site and other

factors and proceed as needed.

NOTE:

Refer to Quick Start Section located near the back of these instructions for Side Profile and

related diagrams

.

If you are not setting ground posts in concrete and are anchoring frame as described in the MUST

READ document, do not auger holes for ground posts. Instead, follow the steps to mark ground

post locations and drive posts into the ground at those locations. See information below and on

next page.

Complete these steps:

1. Stake building outline using string line and batter boards. Set batter boards 3' back from the

building corners. Check to ensure that building layout is square. Cover or panels (if equipped)

will not install properly if frame is not square once assembled.

2. Consult diagrams in Quick Start section to verify frame length and width dimensions and to

accurately position ground posts.

3. Guided by string line, use a flag or stake to mark each ground post hole location.

4. Move string line and dig a post hole a minimum of two

feet (2') deep

or to a depth that is

below geographic frost

line.

Consult local building codes. A power auger works

best.

Minimum hole diameter is 12"

.

5. After digging all holes, reattach string line to batter

boards and use it as a guide to set and align ground

posts.