6

Revision date: 12.30.16

Prepare and Square the Building Site

PREPARE THE BUILDING SITE

A level site is required to accurately and safely construct

the building. Consult the services of a qualified contractor

to properly grade and prepare the site.

Site should slope away from the building for proper water

drainage.

After the site is prepared, mark the location of the frame

corners to square the frame position. Taking these steps

before

assembling the shelter saves time and ensures

that the structure is square and positioned as desired.

The following procedures are suggested methods.

Their use depends on the size of the shelter, shelter

application, the footings (if applicable), and the method

used to anchor the shelter.

When in doubt, consult the services of a qualified

contractor experienced with the construction of similar

structures.

Ground Posts

If the frame includes ground posts, set all ground posts

as described within this manual. Width of the shelter

is measured from the center of one ground post to the

center of the remaining ground post. Length is also

measured center-to-center. If your building includes

ground posts, continue with the Setting Ground Post

section.

SQUARE THE SITE: GENERAL STEPS

1. Identify a corner where a building rafter will be

positioned, drive in a stake, and string a line the exact

width of the building and stake in place. (Width of the

rafter is measured from center-to-center of the rafter

legs.)

2. After the first corner stake is in place, string a line the

width of the building (center-to-center) and drive the

second corner stake into the ground.

3. String a line at least as long as the building 90° from

the line between the first and second stakes.

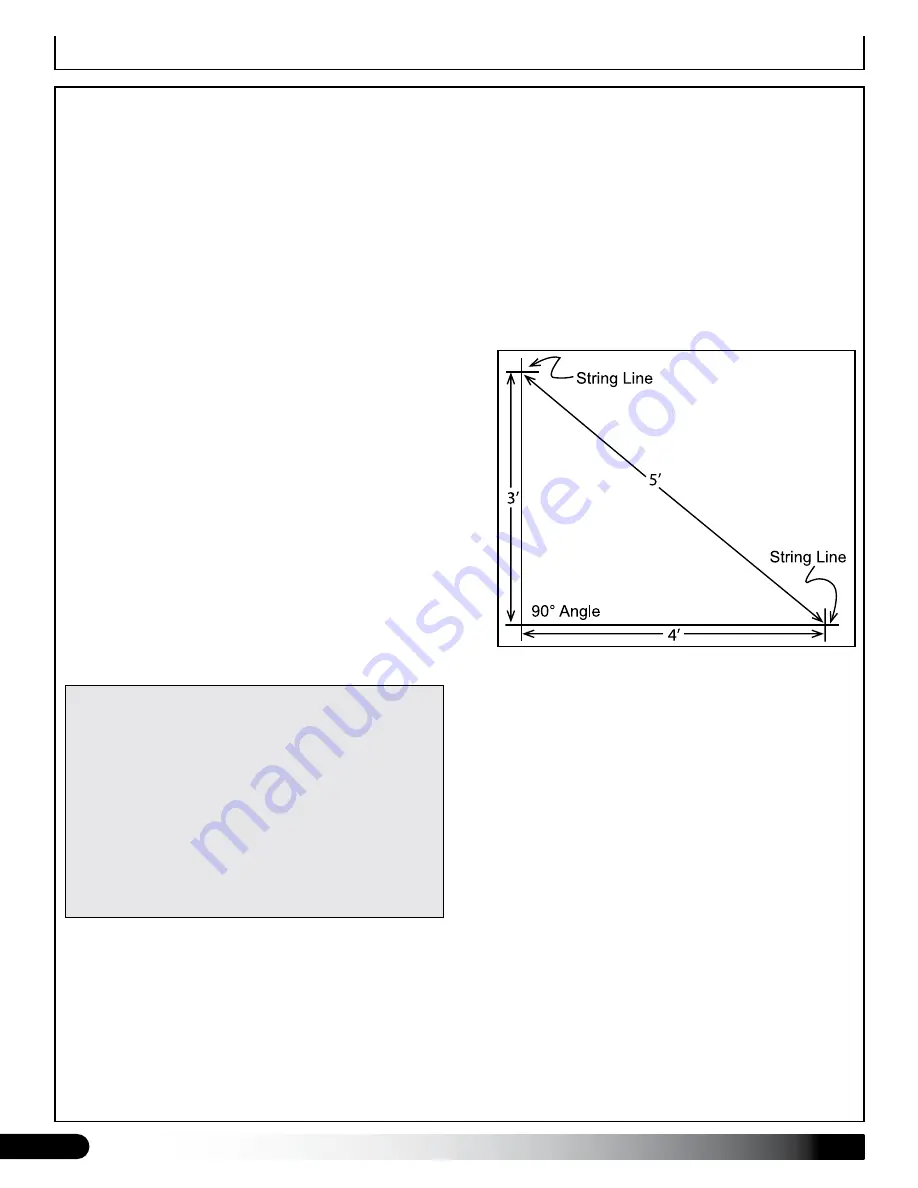

NOTE:

A transit can be used to ensure an accurate

90° angle, or the 3-4-5 rule can be used. Refer to

diagram. Using multiples of 3-4-5 such as 6-8-10 or

12-16-20 helps to maintain an accurate 90° angle.

4. After squaring the position of the building, measure

the length and drive the third corner stake.

5. Repeat the same step for the last corner stake.

NOTE:

The distance measured diagonally between

corner stakes must be equal for the building to be

square.

SETTING THE GROUND POSTS

The frame assembly of this building requires the

setting of all ground post in concrete. Review the

layout diagrams for additional details.

Enlist the services of a professional and competent

contractor to prepare the site and set the ground posts.

Failing to secure ground posts in concrete as required

may result in damage to the building, building contents,

and surrounding property.