GROWSPAN

™

ROUND PRO GREENHOUSES AND SYSTEMS

4

Revision date: 01.23.19

SPECIAL NOTE: Baseboards for Frame

These instructions describe installing a baseboard

(recommended) at ground level along each side of the

frame. The baseboard runs from the front to the back of the

frame.

This baseboard is

not included

with the shipment and must

be supplied by the customer. Treated or recycled plastic

lumber works well for a baseboard.

Use the included 1/4" x 4" (FAH009B) carriage bolts

and the 1/4" zinc nuts (FALB01B) to attach a customer-

supplied baseboard. Depending on the dimensions of the

baseboard, alternative customer-supplied fasteners may be

needed.

During the installation, align the baseboard with the

center of the end rafter. Do not allow the baseboard to

extend beyond the end rafters at either end of the frame.

Doing so will interfere with the installation of the end wall

polycarbonate panels.

The baseboard, when installed properly, helps prevent the

ground posts from sinking into the ground when anchored.

Depending on the building, it also provides a surface to

attach struts or other building components. Consult these

instructions or contact Customer Service for additional

information regarding baseboards.

REQUIRED TOOLS

The following list identifies the main tools needed to

assemble the shelter. Additional tools and supports may be

needed.

• Tape measure or measuring device

• Marker to mark locations on the pipes

• Variable speed clutched drill driver (cordless with

extra batteries works best)

• Saw to cut metal and polycarbonate panels

• Wrenches and impact socket set, or an adjustable

wrench

• Scissors, utility knife, or tin snips

• Hammers, rubber mallet, and gloves

• Flat bar or putty knives for panel installation

• Drill bit set that includes a 5/16" bit

• Chalk line

• Caulk gun to apply sealant

• Adjustable pliers and self-locking pliers

• Ladders, work platforms, and other machinery for lifting

designed to work safely at the height of the building

• Rope for temporary rafter bracing during frame

assembly

ASSEMBLY NOTE:

Install Tek screws using a clutched

drill driver running approximately 750 RPM while applying

approximately 50 lbs of force.

Do not use an impact driver to install Tek screws!

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all the

necessary parts

before

you begin to assemble the shelter

frame.

1. Unpack the contents of the shipment and place where

you can easily inventory the parts. Refer to the Bill of

Materials/Spec Sheets.

2. Verify that all parts listed on the Bill of Materials/Spec

Sheets are present. If anything is missing or you have

questions, consult the Pictorial Parts Guide and all

diagrams for clarification, or contact Customer Service.

NOTE:

At this time, you do not need to open the plastic

bags containing smaller parts such as fasteners or

washers (if equipped).

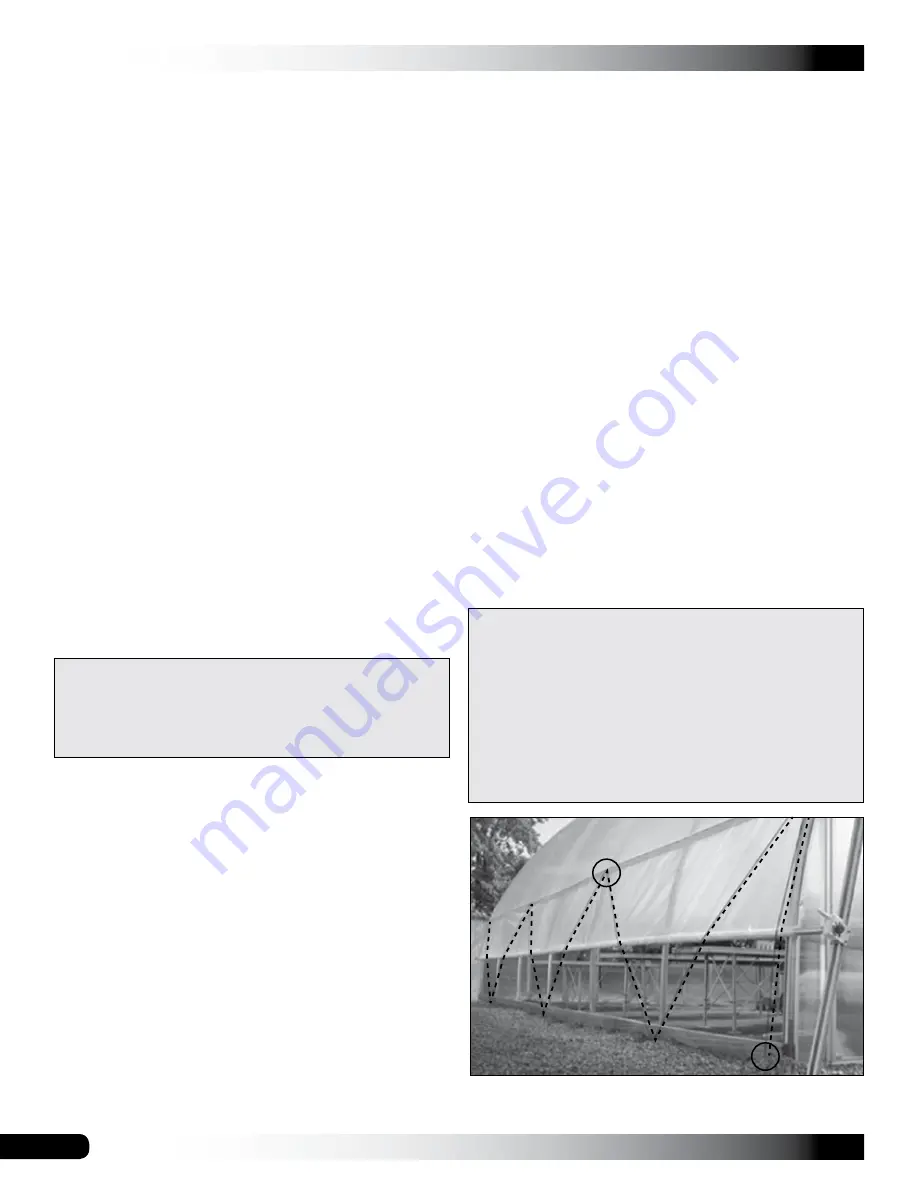

ANTI-BILLOW ROPE INSTALLATION

TO PREVENT DAMAGE AND POSSIBLE INJURY,

INSTALL THE ANTI-BILLOW ROPES IN SHORT

LENGTHS ALONG EACH SIDE OF THE FRAME.

DO NOT INSTALL AS A SINGLE LENGTH TIED AT

EACH END OF THE BUILDING. DOING SO WILL

RESULT IN A LOOSE SIDE PANEL IF THE SINGLE

ROPE BREAKS DURING STRONG WINDS.

Dotted line represents the anti-billow rope. The circles

identify the ends of ROPE #1.

ROPE

#1

ROPE

#2