1

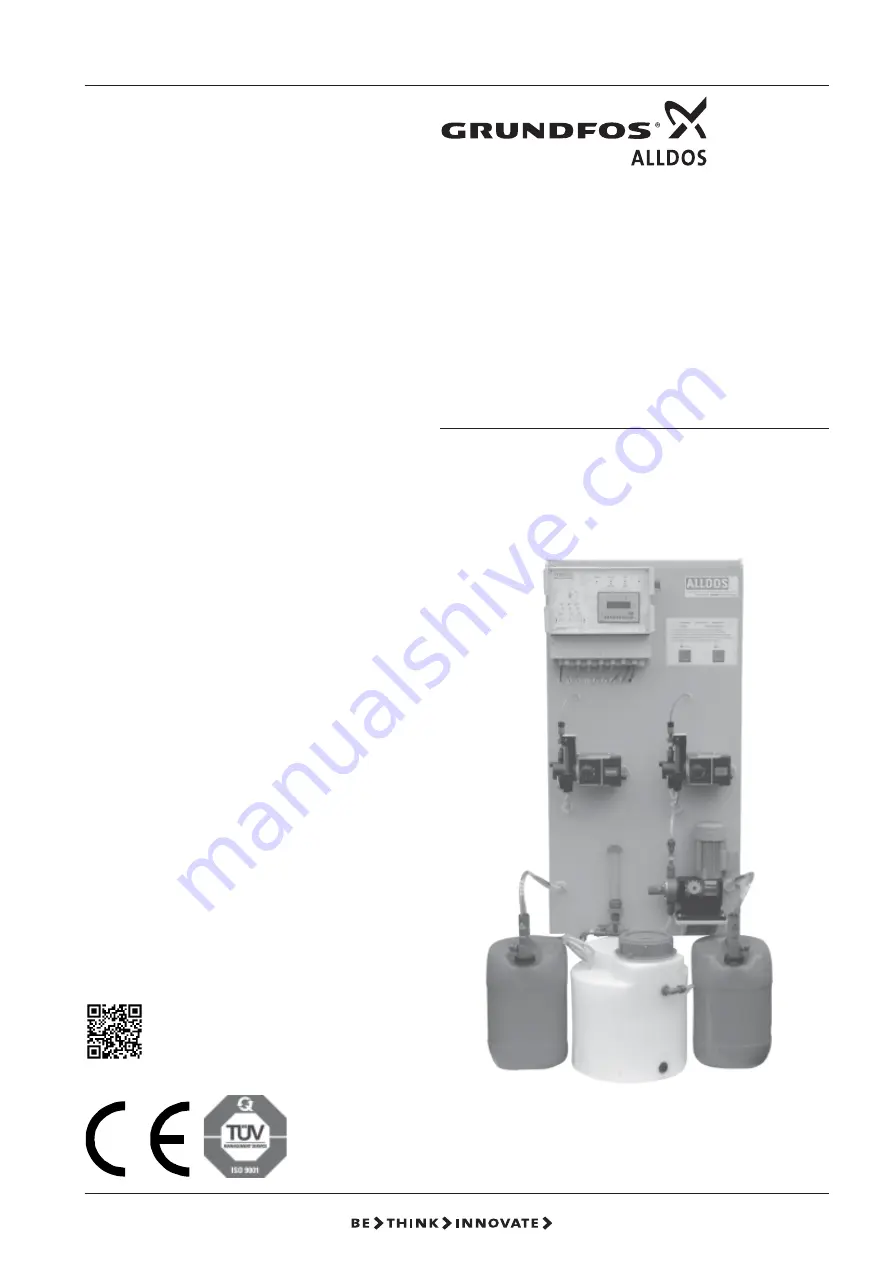

Oxiperm

®

C 164

Fully-automatic Chlorine Dioxi-

de Generation System

164 -150C, -450C, -750C,

-1300C, -2500C

Operation and

Service Manual

Please read the Operation Manual completely and retain for future reference!

Damages resulting from operating errors cancel the guarantee.

Other languages

http://net.grundfos.com/qr/i/96681303

Summary of Contents for Oxiperm C 164 Series

Page 34: ...34 15 710010 V5 0 Oxiperm 164 150 2500 g en...

Page 96: ...96 15 710010 V5 0 Oxiperm 164 150 2500 g en...

Page 115: ......

Page 116: ......

Page 117: ......