10

6. EMC-correct installation

The CU 361 is normally mounted in a panel which

also contains an IO 351 module, frequency

converters, contactors and other power equipment.

In order to ensure a faultless function, it is very

important to install the electronic modules in an

EMC-correct way:

•

Ensure a sufficient earth connection between the

CU 361 and the frame. See fig. 7.

•

Use screened cables for GENIbus. Connect the

screen to the cable clamp of the CU 361 in front

of the terminals A1, Y1 and B1. See fig. 8. Also

use screened cable for the CIM module.

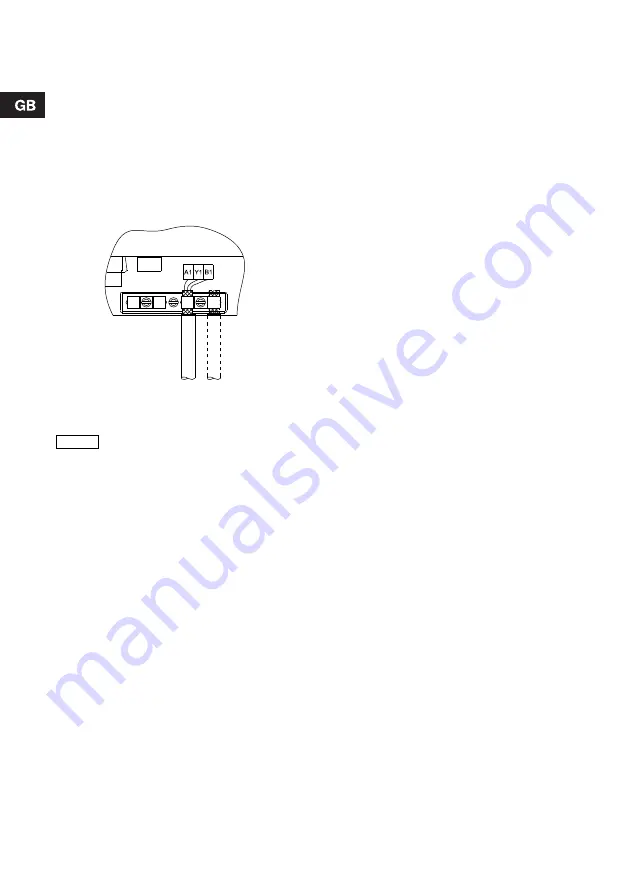

Fig. 8

Screen fixed with cable clamp

•

Signal conductors for digital and analog inputs

and outputs should be screened, i.e. run the

screen all the way to the CU 361 and connect it to

frame with for instance a cable clamp.

Alternatively, the signal conductors in the panel

may be unscreened if the panel is divided into a

power and a low-voltage area. Unscreened signal

conductors must not run in the power area, but

exclusively in ducts in the low-voltage area.

•

Do not twist screen ends to avoid pig tails, as this

will destroy the s creen effect at high frequencies.

Use cable clamps instead.

T

M

04

20

65

19

08

Note

Any isolating plastic tape between

screen and sheath must be removed

before mounting the cable in the cable

clamp.