3.7 Adjusting the dosing flow via the stroke length

Make sure the pump was installed and started up correctly.

Only adjust the stroke length while the pump is running.

•

To increase the dosing flow, turn the adjusting knob slowly to the left.

•

To decrease the dosing flow, turn the adjusting knob slowly to the right.

Related information

• 3.2 Safety instructions and requirements for startup

• 5.1.1 DMX 221 components

• 5.1.2 Functional principle of the pump

• 9.6 Dosing curves

3.8 Adjustment of the stroke rate with a frequency converter

If a frequency converter is connected, the dosing flow can be adjusted by changing the stroke

rate. This can only be done in the range of 10-100 % of the maximum stroke rate.

For more information, read the installation and operating instructions of the frequency converter.

Related information

3.9 Opening and reactivating the integral relief valve

•

Make sure the pump was installed and started up correctly.

•

Make sure the pump is running during this task.

WARNING

Chemical hazard

Death or serious personal injury

● Wear protective clothing when working on the dosing head, connections or

lines.

● Collect and dispose of all chemicals in a way that is not harmful to persons or

the environment.

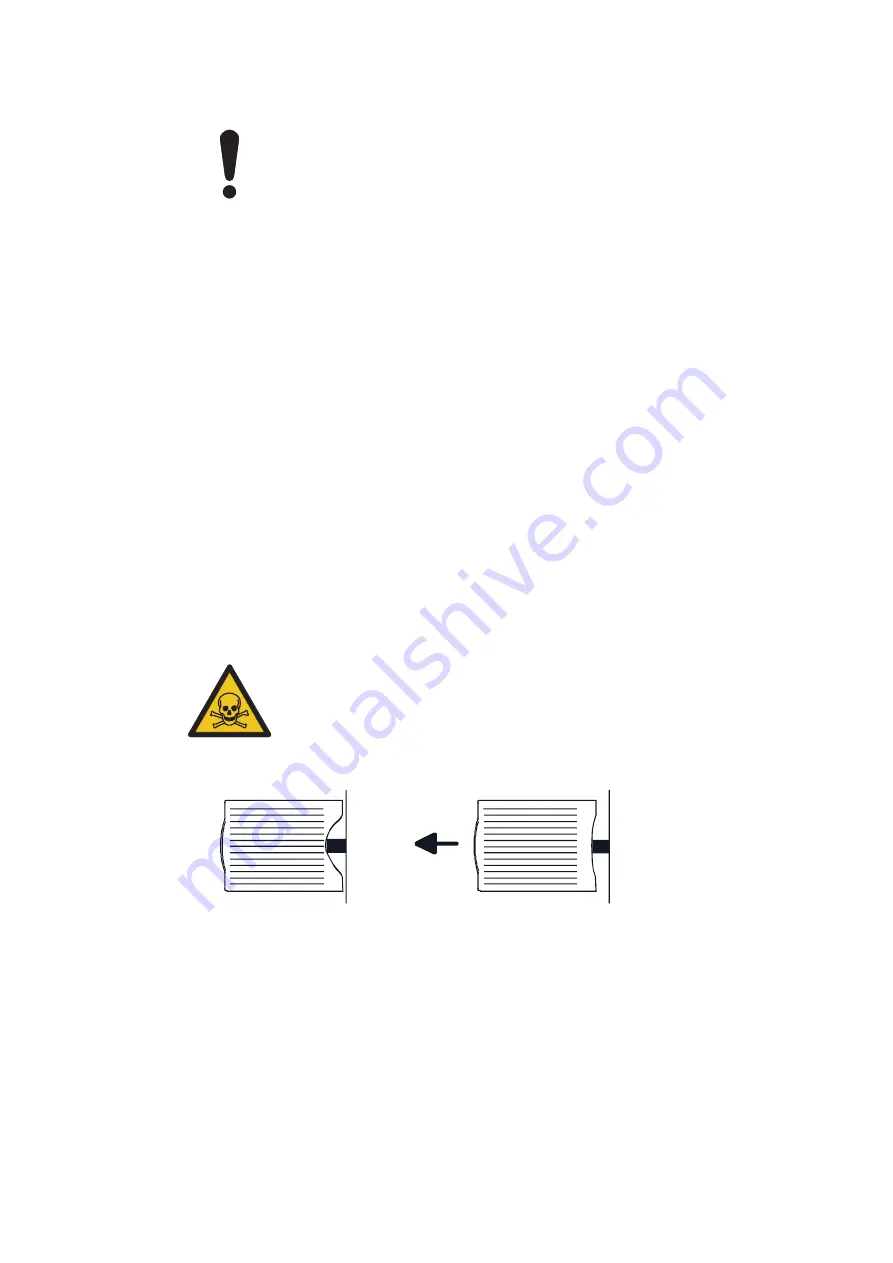

A

B

Fig. 3.9-1 Knob positions

1. To open the relief valve, turn the relief-valve knob to position B.

The relief valve is open. Dosing medium and air can flow out through the overflow line.

2. To reactivate the relief valve, turn the relief-valve knob to position A.

The relief valve is reactivated and will open at the set opening pressure.

Related information

• 3.10 Setting the opening pressure of the integral relief valve

DMX 221 | |

19